The Global Micromachining Market is rapidly gaining traction as industries increasingly demand high-precision components and advanced miniaturization techniques. The Micromachining Market involves specialized manufacturing processes used to create microscale structures and devices with extreme accuracy. These technologies are essential for producing small, complex components used in electronics, medical devices, automotive systems, and aerospace applications.

With continuous advancements in laser technology, automation, and semiconductor processing, micromachining has evolved into a cornerstone of modern manufacturing. It enables the production of intricate parts that meet the growing requirements for miniaturization, energy efficiency, and enhanced performance. According to recent estimates, the Global Micromachining Market is projected to reach USD 3,162.3 million by 2024 and further expand to USD 6,265.0 million by 2033, growing at a CAGR of 7.9%.

The expanding use of microfabrication technologies in medical and electronic components, coupled with increasing industrial automation, is driving the adoption of micromachining solutions worldwide. The shift toward micro-scale precision manufacturing aligns with emerging trends in wearable technology, MEMS sensors, and microelectronics production.

? Request a Free Sample Report: https://dimensionmarketresearch.com/report/micromachining-market/request-sample/

Understanding the Micromachining Market

Micromachining refers to the process of fabricating miniature components with micrometer or even nanometer precision. It is widely used to produce parts for electronics, medical implants, and aerospace systems that require ultra-fine geometries. The process typically uses laser, electrochemical, or ultrasonic methods to remove material from a substrate with exceptional accuracy.

This technology plays a vital role in enabling innovations like microelectromechanical systems (MEMS), microsensors, and lab-on-chip devices, which are transforming healthcare diagnostics, automotive safety systems, and consumer electronics. The ability of micromachining to deliver high repeatability and precision makes it a preferred choice over traditional mechanical machining techniques.

Moreover, the trend toward miniaturization in consumer electronics—such as smartphones, wearables, and advanced optical devices—has accelerated demand for micromachined components. As the Internet of Things (IoT) ecosystem expands, manufacturers are increasingly investing in microfabrication capabilities to support high-volume production of compact sensors and integrated circuits.

Key Market Drivers

1. Rising Demand for Miniaturized Components

The ongoing trend toward miniaturization in electronics, medical devices, and automotive systems is a major driver of market growth. Micromachining enables the production of smaller, lighter, and more efficient components that support high-performance functionality.

2. Advancements in Laser Technology

The adoption of laser-based micromachining processes has revolutionized precision manufacturing. Ultrafast and femtosecond lasers provide unparalleled control and accuracy, allowing for precise cutting, drilling, and surface structuring without thermal damage.

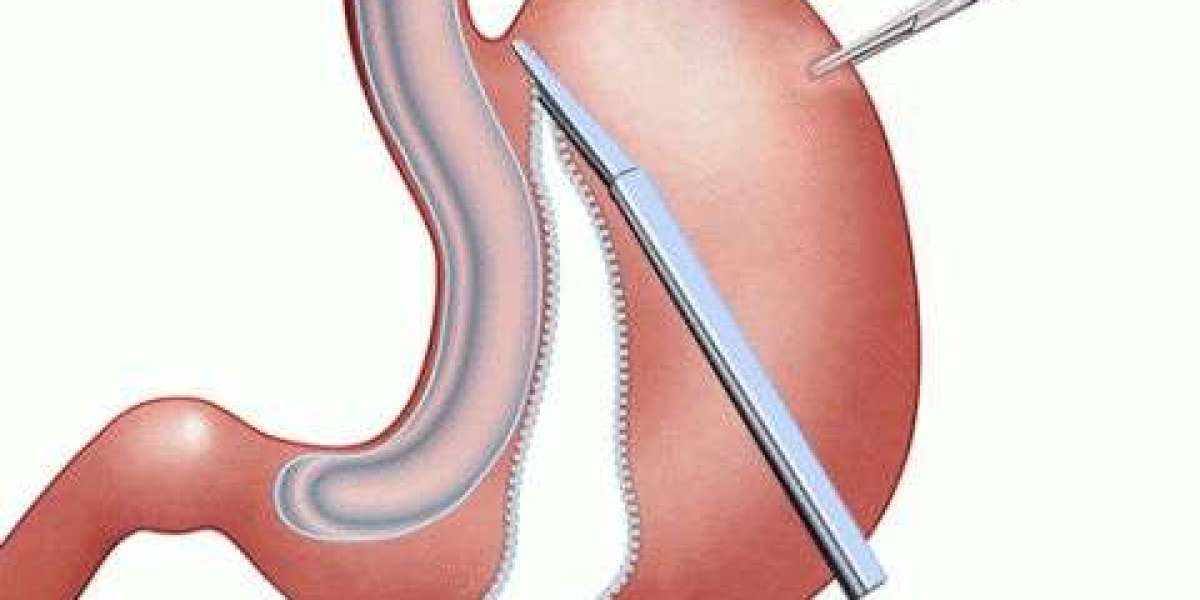

3. Growth in the Medical and Healthcare Sector

Micromachining is crucial in medical device manufacturing, where intricate parts such as stents, catheters, and surgical instruments require micron-level precision. The growing demand for minimally invasive procedures is driving innovations in micro-scale medical technologies.

4. Expansion of Automotive and Aerospace Applications

The automotive and aerospace industries increasingly use micromachining to create lightweight and durable components, improving fuel efficiency and performance. Sensors, actuators, and fluid control systems produced via micromachining are essential for advanced safety and control systems.

5. Emergence of MEMS and Nanotechnology

The growing use of microelectromechanical systems (MEMS) in electronics, sensors, and communication devices is fueling the market’s growth. Micromachining enables the fabrication of MEMS components with high uniformity and precision, supporting innovation in smart devices and IoT systems.

Market Segmentation

The micromachining market can be segmented by type, application, and industry vertical.

By Type:

Laser Micromachining

Electrochemical Micromachining

Ultrasonic Micromachining

Micro-EDM (Electrical Discharge Machining)

Hybrid Micromachining

By Application:

Microfabrication

Micro-molding

Surface Structuring

Micro-drilling and Cutting

Engraving and Patterning

By End-User Industry:

Electronics and Semiconductor

Automotive

Aerospace and Defense

Medical and Healthcare

Industrial Manufacturing

Among these, laser micromachining remains the most dominant segment, owing to its precision, non-contact nature, and ability to process a variety of materials such as metals, ceramics, and polymers.

? Purchase the report for comprehensive details: https://dimensionmarketresearch.com/checkout/micromachining-market/

Regional Analysis

Asia-Pacific – Market Leader

The Asia-Pacific region is projected to lead the Global Micromachining Market with an estimated revenue share of 35.6% in 2024. The dominance of this region stems from the presence of major manufacturing hubs in China, India, South Korea, and Japan. These countries are at the forefront of the electronics, automotive, aerospace, and medical device industries, which heavily rely on micromachining for the production of high-precision components.

China’s thriving semiconductor and electronics manufacturing ecosystem drives substantial demand for laser and electrochemical micromachining tools. Meanwhile, India’s expanding automotive industry and South Korea’s leadership in semiconductor fabrication contribute to the region’s growth momentum.

The continuous rise in demand for smartphones, electric vehicles, and miniaturized medical instruments further solidifies Asia-Pacific’s position as the global hub for micromachining technologies. The availability of skilled labor, government support for advanced manufacturing, and growing investments in automation are reinforcing regional market expansion.

North America

North America holds a significant market share, primarily driven by technological advancements and the adoption of precision manufacturing techniques in aerospace and healthcare industries. The United States, with its strong presence of medical device and defense manufacturers, continues to invest in advanced micromachining solutions to improve component reliability and performance.

Europe

Europe’s market growth is supported by its well-established automotive and industrial sectors. Countries like Germany, the UK, and France are investing in micromachining for high-end engineering applications, including aerospace components and energy-efficient machinery. The emphasis on quality, sustainability, and automation enhances the adoption rate of micromachining technologies in the region.

Rest of the World

Regions such as the Middle East, Africa, and Latin America are gradually adopting micromachining technologies as part of their industrial modernization efforts. Growing medical and automotive sectors, coupled with foreign investments, are expected to contribute to the region’s steady growth over the next decade.

Emerging Market Trends

Integration of AI and Machine Learning: Smart micromachining systems are leveraging artificial intelligence to optimize process parameters, minimize waste, and enhance precision.

Additive-Subtractive Hybrid Manufacturing: Combining micromachining with 3D printing offers a flexible and efficient approach to producing complex geometries.

Green Manufacturing Initiatives: Environmental sustainability is becoming a priority, with manufacturers adopting cleaner, energy-efficient micromachining processes.

Miniaturization of Medical Devices: Growing demand for micro implants, biosensors, and diagnostic tools is fostering advancements in micromachining.

Automation and Robotics Integration: Automated micromachining systems improve throughput, consistency, and safety in production environments.

Competitive Landscape

The Global Micromachining Market is characterized by intense competition among key manufacturers focusing on innovation, product enhancement, and cost efficiency. Companies are investing heavily in R&D to develop laser systems with better beam control and higher productivity.

Strategic partnerships between micromachining tool manufacturers and end-user industries are helping tailor solutions for specific applications such as semiconductor wafer cutting, stent fabrication, and microelectronics assembly.

Leading players are also expanding their geographical presence to cater to the growing industrial base in emerging economies, particularly in Asia-Pacific.

Future Outlook

The future of the Global Micromachining Market is shaped by increasing technological sophistication, automation, and cross-industry integration. As miniaturization becomes a fundamental requirement in modern products, micromachining will continue to play a critical role in manufacturing innovation.

The growing importance of precision engineering, combined with the demand for compact and lightweight components, will create sustained opportunities across multiple industries. Moreover, as laser technology and nanomanufacturing continue to evolve, micromachining processes are expected to achieve even higher accuracy and production efficiency.

Over the coming decade, advancements in MEMS devices, optical communication systems, and biomedical applications will drive strong market expansion. With its ability to deliver ultra-precise, repeatable, and environmentally friendly manufacturing, micromachining stands as a cornerstone of the next industrial revolution.

FAQs about the Global Micromachining Market

1. What is the size of the Global Micromachining Market?

The market is valued at USD 3,162.3 million in 2024 and is projected to reach USD 6,265.0 million by 2033, growing at a CAGR of 7.9%.

2. Which region dominates the micromachining market?

The Asia-Pacific region leads with an estimated 35.6% share in 2024, driven by its strong electronics, automotive, and medical device manufacturing sectors.

3. What are the main applications of micromachining?

Micromachining is primarily used for micro-drilling, cutting, engraving, surface structuring, and precision component manufacturing across electronics, medical, and aerospace industries.

4. What technologies are used in micromachining?

Key technologies include laser micromachining, electrochemical micromachining, ultrasonic micromachining, and micro-EDM. Among these, laser-based processes hold the largest market share due to their precision and versatility.

5. What factors are driving the growth of the micromachining market?

Rising demand for miniaturized electronic and medical components, technological advancements in laser systems, and the adoption of Industry 4.0 manufacturing processes are major growth drivers.

Summary of Key Insights

The Global Micromachining Market is poised for strong and sustained growth over the next decade. Its expansion is fueled by increasing demand for miniaturized, high-precision components across multiple sectors such as electronics, medical devices, and automotive manufacturing.

With technological advancements in laser processing, automation, and smart manufacturing, micromachining continues to evolve as a vital technology for achieving efficiency and innovation. The Asia-Pacific region, leading the market with over one-third of global revenue, highlights the growing importance of precision manufacturing in emerging economies.

As industries embrace miniaturization, sustainability, and digital transformation, micromachining will remain a critical enabler of the global shift toward advanced manufacturing solutions.