The Industrial Internet of Things (IIoT) has become the core enabler of digital transformation across manufacturing, energy, utilities, transportation, and other industrial sectors. As organizations accelerate their move toward connected operations and data-driven decision-making, the role of Industrial IoT platforms is evolving rapidly. Modern IIoT platforms are no longer limited to device connectivity or basic monitoring—they now serve as intelligent, autonomous ecosystems that drive real-time optimization, predictive insights, and industry-wide interoperability.

QKS Group’s Spark Matrix Industrial Internet of Things Platform market research delivers a comprehensive analysis of the global IIoT landscape, evaluating key market trends, technology advancements, and strategic growth opportunities. The research offers essential insights for technology vendors to better understand the evolving market and for industrial organizations to assess vendor capabilities, innovation maturity, and competitive positioning.

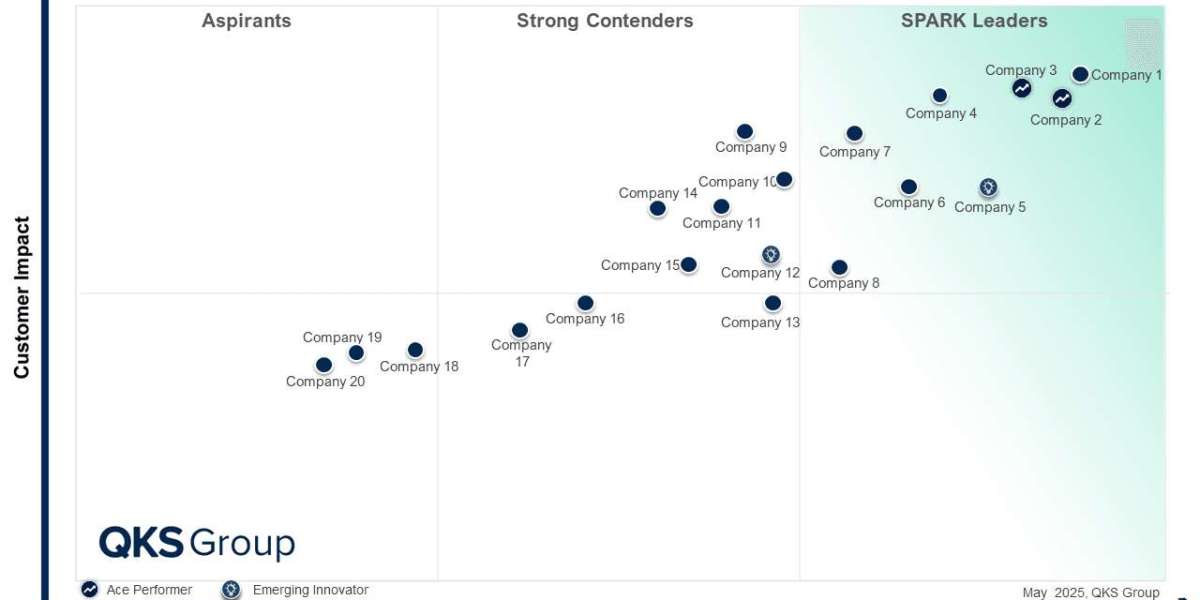

A major highlight of this research is the proprietary SPARK Matrix analysis, which provides a detailed evaluation and ranking of leading IIoT platform providers based on their technological excellence, customer impact, and global market presence. The SPARK Matrix covers established and emerging vendors such as ABB, Actility, Altizon, AWS, Braincube, Cisco, Cumulocity, Davra, Eurotech, Exosite, Inductive Automation, Litmus, Losant, Microsoft, PTC, ROOTCLOUD, Samsung SDS, Siemens, Telit Cinterion, and Univers. These vendors are shaping the next wave of industrial digitalization through innovation in edge computing, AI-driven automation, streaming analytics, and cross-ecosystem integration.

The Evolving Role of IIoT Platforms in Modern Industrial Ecosystems

Industrial operations are becoming more complex and highly distributed, with machines, sensors, controllers, and applications generating data at unprecedented scale. IIoT platforms play a critical role by unifying these data streams, enabling real-time monitoring, remote operations, and process optimization. However, the next generation of IIoT platforms goes beyond foundational capabilities—driving industrial transformation through AI, autonomy, and automation.

Key capabilities of modern IIoT platforms include:

- Device and Asset Connectivity: Supporting diverse protocols such as MQTT, OPC UA, Modbus, and proprietary industrial standards.

- Unified Data Layer: Aggregating, contextualizing, and visualizing data from machines, sensors, and enterprise applications.

- Edge & Fog Computing: Processing data closer to the source for reduced latency and improved reliability.

- AI/ML-Driven Insights: Enabling predictive maintenance, anomaly detection, and optimization models.

- Digital Twins: Creating virtual models of assets and processes for simulation, diagnostics, and continuous optimization.

- Workflow Automation: Orchestrating processes across production lines, logistics systems, and maintenance operations.

As industrial enterprises adopt Industry 4.0 initiatives, IIoT platforms have become the foundation for connected factories, smart energy grids, digital supply chains, and autonomous industrial systems.

Key Market Trends Shaping the Future of IIoT Platforms

QKS Group’s research highlights several emerging technology and market trends that are accelerating the shift toward intelligent, autonomous, and interoperable industrial ecosystems.

- The Rise of the Unified Namespace (UNS)

One of the most transformative developments in the IIoT space is the emergence of the Unified Namespace (UNS). UNS acts as a real-time, hierarchical data architecture that connects OT systems, IT systems, and enterprise applications into a unified data fabric.

By breaking long-standing data silos, UNS provides a centralized data layer that supports interoperability, scalability, and real-time decision-making across industrial environments. This shift is enabling industries to transition from isolated data pockets to connected and transparent digital ecosystems.

- Shift Toward Modular, Open, and API-Driven Architectures

Traditional industrial platforms were often rigid and proprietary, limiting flexibility and integration. The new generation of platforms is embracing open standards, containerized environments, microservices, and API-first design.

This transition supports plug-and-play integration, rapid deployment, and vendor-agnostic interoperability—allowing organizations to build tailored industrial solutions without being locked into a single ecosystem.

- Edge-to-Cloud Intelligence for Real-Time Automation

Industrial environments demand ultra-low latency and high resilience. As a result, IIoT platforms are becoming increasingly edge-native, deploying machine learning models and analytics at the edge.

This enables factories and industrial systems to operate autonomously, even when cloud connectivity is inconsistent. The seamless flow of intelligence between the edge and the cloud is shaping the future of resilient, real-time industrial automation.

- Autonomous Operations and Self-Optimizing Systems

With advancements in AI, machine learning, and digital twins, IIoT platforms are evolving from systems that inform to systems that autonomously operate and optimize industrial processes.

This includes self-calibrating machines, automatically adjusting production parameters, and fully automated maintenance cycles—creating a new era of smart, adaptive industrial operations.

- Sustainability and Energy Intelligence

Industrial sustainability initiatives are driving increased adoption of IIoT platforms. Modern solutions enable real-time energy monitoring, emissions tracking, and optimization of resource usage.

Sustainability-driven operations—powered by IIoT insights—support global decarbonization goals and offer cost savings through improved operational efficiency.

SPARK Matrix: Understanding Vendor Capabilities and Differentiation

The SPARK Matrix assessment within the QKS Group research provides actionable insights into how leading vendors differentiate themselves through innovation, scalability, usability, integration capability, and customer impact.

The evaluation helps enterprises understand:

- Strength of platform architecture and deployment flexibility

- Industry-specific solution accelerators

- Breadth of edge and connectivity capabilities

- AI/ML maturity and analytics sophistication

- Ability to support UNS and open industrial architectures

- Ecosystem partnerships and marketplace integrations

- Customer support, vision alignment, and long-term viability

Enterprises can use the SPARK Matrix insights to identify the right vendor based on specific industrial requirements—ranging from manufacturing and energy to logistics, oil & gas, and utilities.

Future Outlook: Toward Autonomous, Sustainable, and Interoperable Industrial Enterprises

The global IIoT platform market is entering a new era—one defined by autonomy, intelligence, and interoperability. As industries continue to prioritize digital transformation, IIoT platforms will serve as the backbone for:

- Autonomous industrial operations

- Real-time decisioning powered by AI and UNS

- Sustainable and energy-efficient ecosystems

- Cyber-resilient and secure industrial networks

- Seamless IT-OT convergence

- Scalable multi-vendor integration

As industrial enterprises modernize, the demand for IIoT platforms that deliver end-to-end intelligence and operational excellence will only continue to grow.

#IIoTPlatform #IndustrialIoT #SmartManufacturing #DigitalIndustrialTransformation #SPARKMatrix