Category: Indicator

In the world of industrial automation, clarity and feedback are everything. Whether it’s a flashing LED on a control panel or a digital display showing process data, indicators serve as the eyes of automation systems — providing real-time visual cues that help operators monitor, control, and respond to system conditions instantly. These small yet powerful devices play a vital role in ensuring safety, efficiency, and smooth operation across industries.

What Is an Indicator?

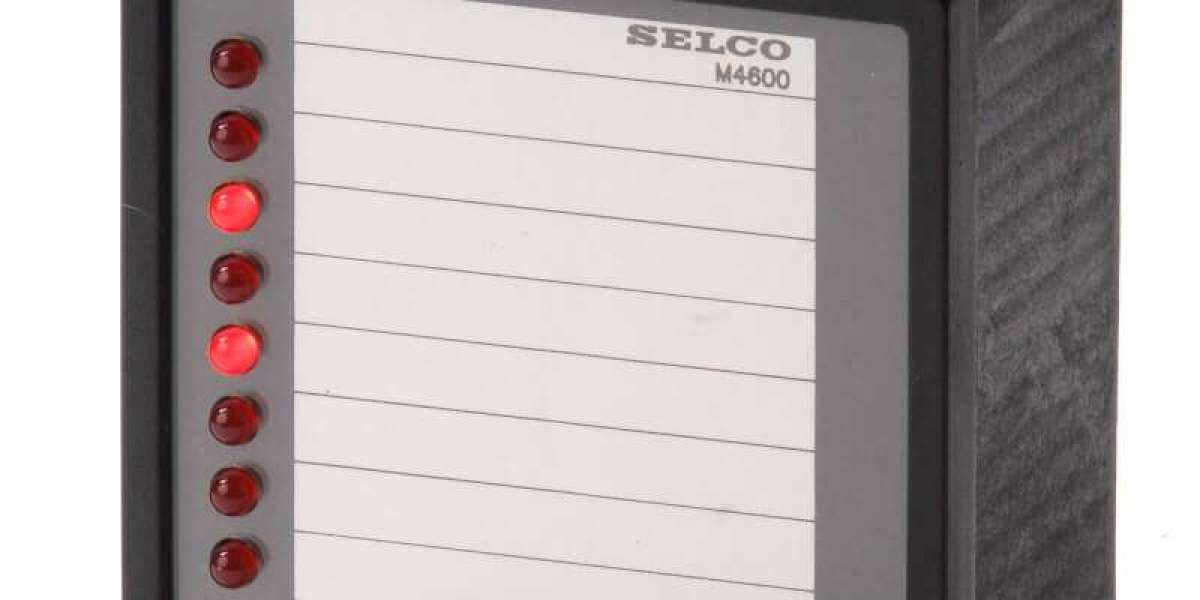

Indicators can take many forms — from simple pilot lights to advanced digital displays — and are used to convey essential data such as power status, operating mode, faults, or measurements.

In automation, indicators act as an interface between humans and machines, allowing operators to quickly understand what’s happening within complex systems without needing detailed diagnostics.

How Indicators Work

Indicators operate by converting electrical signals into visible or readable outputs. Depending on the design, they may use LEDs, LCDs, analog meters, or signal lamps to display specific system conditions.

For example:

- A green light might show normal operation.

- A red light could indicate a fault or emergency stop.

- A digital display might show temperature, voltage, or process speed.

By simplifying complex electrical signals into intuitive visuals, indicators help minimize human error and enhance decision-making in real-time operations.

Types of Indicators

Different types of indicators are used based on the application and information required:

- Pilot Indicators – Simple on/off lights that show equipment status.

• Signal Lamps – Used in panels to indicate operational or alarm conditions.

• Analog Indicators – Needle-based gauges showing variable data like pressure or current.

• Digital Indicators – Provide numeric readouts for precise monitoring of process values.

• Multi-Color Indicators – Offer multiple states (e.g., green for normal, amber for warning, red for fault).

• Smart Indicators – Integrated with sensors and PLCs for intelligent process feedback.

Why Indicators Matter in Automation

In automated environments, instant feedback is critical. Indicators enhance both safety and efficiency by providing:

- Quick Status Monitoring – Enables operators to identify system states at a glance.

• Fault Detection – Alerts users to malfunctions or abnormal conditions immediately.

• Improved Productivity – Reduces downtime by facilitating faster troubleshooting.

• Operator Safety – Warns of hazardous situations before they escalate.

• Seamless Integration – Works with PLCs, HMIs, and SCADA systems for centralized control.

Common Applications of Indicators

Indicators are used across nearly every industry where automation and monitoring are essential:

- Control Panels – Provide system status and fault alerts in electrical panels.

• Manufacturing Lines – Show machine readiness, process completion, or errors.

• Energy Systems – Indicate voltage, current, and load conditions.

• Transportation & Logistics – Used in signaling systems and vehicle dashboards.

• Building Automation – Show HVAC performance, lighting status, and alarm notifications.

The Future of Indicator Technology

As industries adopt Industry 4.0 technologies, indicators are becoming more advanced and connected than ever. Future developments include:

- IoT-Enabled Indicators – Communicate data to cloud-based dashboards for remote monitoring.

• Smart LED Arrays – Adapt brightness, color, and patterns dynamically for better visibility.

• Touch and Interactive Displays – Combine indication and control in one compact device.

• Energy-Efficient Designs – Use low-power components for sustainable automation systems.

• Integration with AI Systems – Enable predictive alerts and intelligent fault detection.

Closing Note

Indicators may seem simple, but their impact on automation is profound. By delivering clear, reliable feedback, they empower operators to act with confidence — ensuring every process runs safely, smoothly, and efficiently.

In a world driven by data and precision, indicators remain the silent communicators of control — illuminating the path toward smarter, more responsive automation.

? Call us: +1 (234) 288 1755

? Email: [email protected]