IMARC Group, a leading market research company, has recently released a report titled “Digital Manufacturing Market Report by Component (Software, Services), Process Type (Computer-Based Designing, Computer-Based Simulation, Computer 3D Visualization, Analytics, and Others), Application (Automation and Transportation, Aerospace and Defense, Consumer Electronics, Utilities and Processes, Industrial Machinery, and Others), and Region 2025-2033”. The study provides a detailed analysis of the industry, including the digital manufacturing market trends, growth, size, and industry growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How Big Is the global digital manufacturing market?

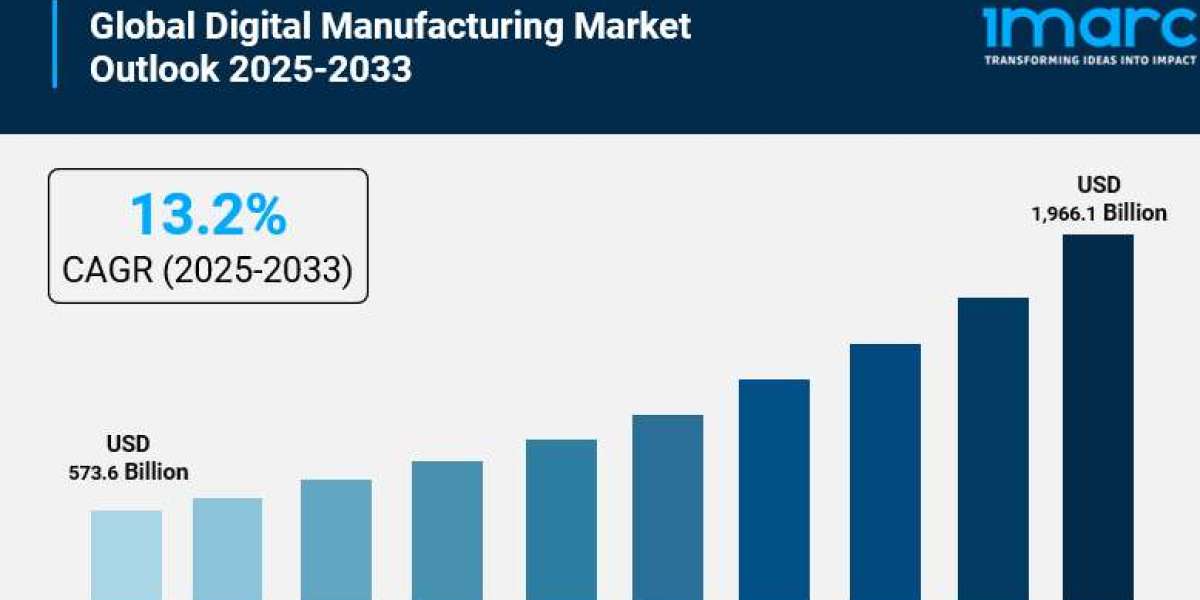

The global digital manufacturing market size reached USD 573.6 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 1,966.1 Billion by 2033, exhibiting a growth rate (CAGR) of 13.2% during 2025-2033.

Rising Adoption of Industry 4.0 Technologies

One of the significant trends that is reshaping the future of production systems is the digital manufacturing market, which is experiencing industry-wide changes brought about by the adoption of Industry 4.0 technologies. The Internet of Things (IoT), artificial intelligence, robotics, and digital twins are some of the advanced technologies that are leading to the shift of traditional manufacturing into smart and connected systems. Such integration enables manufacturers not only extend to possible predictive maintenance, cut the idle time but also simplify the flow of logistics in the supply chain network. In 2025 digital manufacturers are requested to respond quickly to a growing need for a higher level of efficiency with lower operational costs that further is expected to lead to a stronger adoption of digital manufacturing in the automotive, aerospace, and electronics sectors where real-time data and automation make it possible to accelerate the innovations and outputs of higher quality.

Growing Need for Customization and Agile Production

The digital manufacturing market drives by one of the major factors which are consumer demand for personalized and customized products. Companies are utilizing 3D printing, computer-aided design (CAD), and cloud-based platforms to deliver customer-oriented solutions faster and more effectively. In addition, digital manufacturing also allows manufacturers to adjust to changing market needs without getting stuck with waste, both material and of process. In 2025 companies needing the ability to adapt production systems to shifting market scenarios, thus turning the tides toward on-demand manufacturing models in the sectors such as healthcare, fashion and automotive, are demanding agile production systems. The latter opens up the field for more creative product-making, faster prototyping processes, and scalable production, which becomes a business leader in the digital manufacturing market as a go-to growth strategy.

Integration of Sustainability and Smart Materials

On top of that, sustainability is slowly becoming a point the manufacturer must consider when making his decisions; and digital manufacturing is a crucial part in the whole process of eco-friendly practices. By applying advanced simulation instruments and analytics tools, companies can maximize the use of their resources, decrease the consumption of energy, and lower waste resulting from production activities. The association between the usage of smart materials and the application of recyclable components is also part of the ongoing modernization of digital production systems in their efficient usage. In the year of 2025, industries are more focused on controlling their carbon footprints and on following environmental regulations. Digital manufacturing, however, is the only reliable way of coming up with such empowering solutions. Not only does this practice support business sustainability initiatives but it keeps up with the increasing consumer need for green and responsible products.

Digital Manufacturing Market Trends 2025

The digital manufacturing market is rapidly growing with the implementation of novel trends that have the potential to substantially transform production methods. The deployment of digital twin technology, through which manufacturers can reproduce, supervise, and adjust their physical operations virtually is one of the foremost phenomena among the different changes in 2025. Consequently, collaboration platforms that are cloud-based have a similar exposure, permitting effortlessly functioning teams scattered in different parts of the world to carry out the design, testing, and manufacture of their products. In addition to that, the fusion of AI within the operation of production machinery has emerged as a pivotal trend permitting the implementation of smart judgment, control of quality, and prescriptive data analysis. Additive manufacturing is being utilized as the main method of production that is more economical for both small and large-scale productions, especially for prototyping purposes. Furthermore, the element of cybersecurity is progressively more emphasized as the level of safety is raised by the inclusion of sophisticated security measures which aim at protecting sensitive data in the connected production environment. These improvements are illustrative of the fact that, in 2025, innovations in digital manufacturing are no longer just tools for support, but rather central to the global competition among industries

Get your Sample of Digital Manufacturing Market Insights for Free: https://www.imarcgroup.com/digital-manufacturing-market/requestsample

Industry Segmentation:

Digital Manufacturing Market Report Segmentation:

Segmentation By Component:

- Software

- Services

Segmentation By Process Type:

- Computer-Based Designing

- Computer-Based Simulation

- Computer 3D Visualization

- Analytics

- Others

Segmentation By Application:

- Automation and Transportation

- Aerospace and Defense

- Consumer Electronics

- Utilities and Processes

- Industrial Machinery

- Others

Regional Insights:

- North America

- Europe

- Asia Pacific

- Middle East and Africa

- Latin America

Who are the key players operating in the industry?

The report covers the major market players including:

- Autodesk Inc.

- Bentley Systems

- Incorporated CAD Schroer GmbH

- Dassault Systemes S.A.

- Mentor Graphics Corporation

- Siemens Aktiengesellschaft

- PTC Inc.

Ask Our Expert & Browse Full Report with TOC & List of Figure: https://www.imarcgroup.com/request?type=report&id=2048&flag=E

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services.

IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302