IMARC Group, a leading market research company, has recently releases a report titled “Shape Memory Alloys Market Size, Share, Trends and Forecast by Alloy Type, End-Use Industry, Functionality Type, Application, and Region, 2025-2033.” The study provides a detailed analysis of the industry, including the global shape memory alloys market share, size, growth, trends, and forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Shape Memory Alloys Market Highlights:

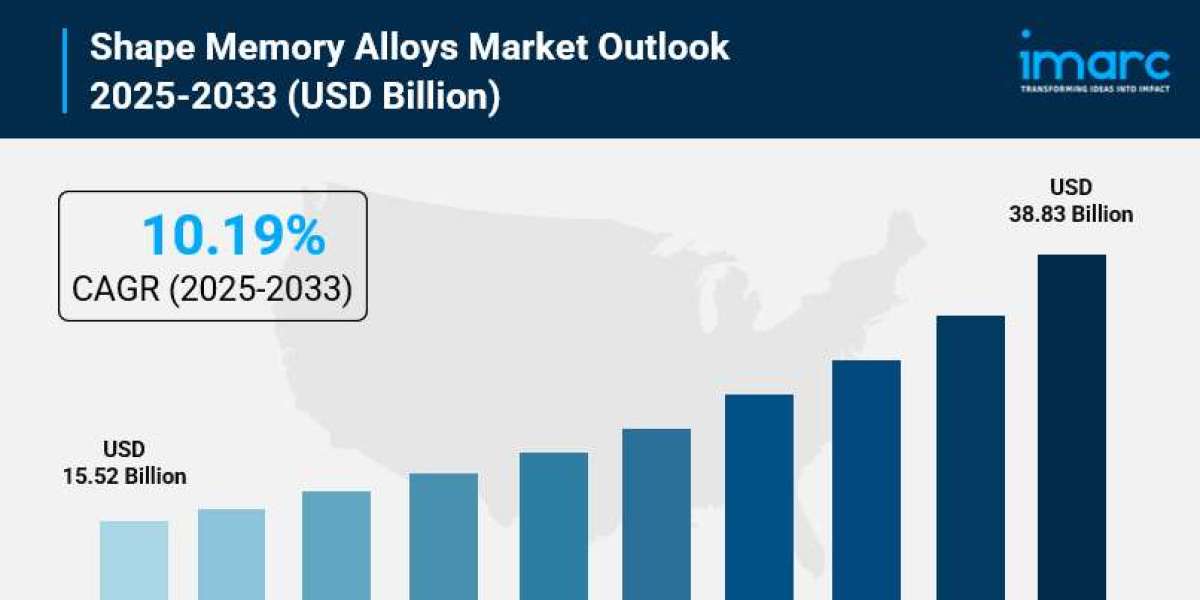

- Shape Memory Alloys Market Size: Valued at USD 15.52 Billion in 2024.

- Shape Memory Alloys Market Forecast: The market is expected to reach USD 38.83 Billion by 2033, growing at an impressive rate of 10.19% annually.

- Market Growth: The shape memory alloys market is experiencing robust growth driven by expanding applications across medical, aerospace, automotive, and electronics sectors.

- Technology Integration: Advanced applications in biomedical devices, actuator systems, and smart materials are revolutionizing how industries approach design and functionality.

- Regional Leadership: North America commands the largest market share at 37.5%, powered by strong industrial demand and cutting-edge research facilities.

- Medical Innovation: Rising demand for minimally invasive medical devices and advanced surgical tools is driving substantial investments in shape memory alloy technologies.

- Key Players: Industry leaders include Allegheny Technologies, DYNALLOY, Inc., EUROFLEX GmbH, Fort Wayne Metals, Nippon Steel Group, and SAES Getters S.p.A., which dominate the market with innovative solutions.

- Market Challenges: High production costs and the need for specialized manufacturing processes present ongoing challenges.

Request for a sample copy of the report: https://www.imarcgroup.com/shape-memory-alloys-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends and Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Industry Trends and Drivers:

- Explosive Growth in Vehicle Production:

The automotive sector is witnessing unprecedented expansion, creating massive opportunities for shape memory alloys. In 2024, worldwide car sales reached 74.6 Million units, showcasing a 2.5% increase from 2023. This surge in vehicle production is creating enormous pressure on manufacturers to adopt advanced materials that offer flexibility, precision, and durability. Shape memory alloys, especially nickel-titanium, deliver excellent properties like high strength, flexibility, and corrosion resistance, making them perfect for automotive applications. These innovative materials are being integrated into components such as actuators, sensors, and adaptive systems, improving vehicle performance and safety. They help optimize features like adjustable seats, mirrors, and airbags. Their ability to respond to temperature changes and perform mechanical movements without external power makes them highly suitable for modern energy-efficient vehicles. As the demand for electric and autonomous vehicles continues growing, the need for advanced materials like shape memory alloys keeps increasing, positioning the automotive industry as a major growth driver.

- Revolutionary Medical Device Innovation:

The biomedical sector is experiencing a transformation thanks to shape memory alloys. These remarkable materials, particularly nickel-titanium, offer excellent biocompatibility, corrosion resistance, and elasticity that make them ideal for implants and surgical tools. They're being widely used in stents, dental wires, orthopedic implants, and minimally invasive surgical devices. These materials adapt to body conditions and return to their original shape after deformation, helping improve patient comfort and recovery. The demand for advanced medical devices continues rising due to increasing surgeries, aging populations, and chronic health conditions. Shape memory alloys also reduce complications and support faster healing, which boosts their utilization in modern healthcare. Their flexibility and responsiveness allow innovations in robotic surgery and micro devices. Healthcare professionals are increasingly recognizing that these materials enable more precise procedures with better patient outcomes, driving widespread adoption across medical facilities.

- Massive Consumer Electronics Expansion:

The consumer electronics industry is experiencing explosive growth, creating substantial demand for compact and efficient materials like shape memory alloys. India is set to reach a USD 1 Trillion digital economy by FY26, with its electronics sector estimated at USD 155 Billion, 65% of which originates from local production. Shape memory alloys are proving ideal for miniaturized devices due to their ability to change shape in response to temperature or electrical signals. They're being used in various electronic components such as microactuators, switches, and connectors, enabling more precise and reliable operations. As the consumer electronics industry evolves, shape memory alloys help improve device performance, reduce size, and increase longevity. Their use in mobile phones, laptops, wearables, and other gadgets allows smarter and more efficient designs. The Asia-Pacific region is particularly dynamic, with household electronics usage in India projected to reach USD 270 Billion by 2030, highlighting the rising demand for advanced materials in compact and high-performance devices.

- Accelerating Construction and Infrastructure Development

Construction activities worldwide are expanding at an impressive pace, creating significant opportunities for shape memory alloys. Nominal construction expenditures were anticipated to hit USD 14.7 Trillion in 2024 and USD 15.6 Trillion by 2025, indicating a 3.2% and 6.4% rise year-over-year, respectively. Shape memory alloys offer unique properties like super-elasticity and corrosion resistance, making them ideal for applications in buildings, bridges, and infrastructure. These innovative materials are being used in seismic and structural reinforcement systems, allowing buildings to respond to stress and vibrations during earthquakes and extreme weather conditions. Shape memory alloys are also being employed in smart structures, where they enable self-healing and adaptive features to improve durability and safety. As urbanization activities accelerate and construction projects become more complex, the need for high-performance materials keeps increasing. Their ability to perform under dynamic conditions and enhance structural integrity is fueling market expansion across infrastructure projects globally.

Shape Memory Alloys Market Report Segmentation:

Breakup by Alloy Type:

- Nickel-Titanium

- Copper-Based Alloys

- Iron-Manganese-Silicon

- Others

Nickel-titanium dominates with 71.2% market share, remaining the preferred choice across industries due to its exceptional shape memory effect, super elasticity, and corrosion resistance.

Breakup by End-Use Industry:

- Biomedical

- Aerospace & Defense

- Automotive

- Consumer Electronics & Home Appliances

- Others

Biomedical leads with 43.7% market share, reflecting the widespread adoption in medical devices, surgical tools, and implantable solutions that improve patient outcomes.

Breakup by Functionality Type:

- Super-elasticity (or Pseudoelasticity)

- Constrained Recovery

- Free Recovery

- Others

Super-elasticity represents the most utilized functionality type, as it allows materials to undergo large strains and return to their original shape without temperature changes, perfect for medical and high-stress applications.

Breakup by Application:

- Laser

- Motors and Actuators

- Transducers

- Structural Material

- Sensors

- Others

Motors and actuators command 30.3% market share, representing the backbone of automation and precision control systems across robotics, aerospace, and automotive sectors.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Who are the key players operating in the industry?

The report covers the major market players including:

- Allegheny Technologies

- DYNALLOY, Inc.

- EUROFLEX GmbH

- Fort Wayne Metals

- RAU GmbH & Co. KG

- Metalwerks, Inc.

- Nippon Steel Group

- SAES Getters S.p.A.

- Furukawa Electric Co., Ltd.

- TiNi Aerospace, Inc.

- Ultimate NiTi Technologies

Ask Analyst For Request Customization: https://www.imarcgroup.com/request?type=report&id=1862&flag=E

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services.

IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302