Global Artificial Intelligence (AI) in Manufacturing Market Outlook 2024–2030

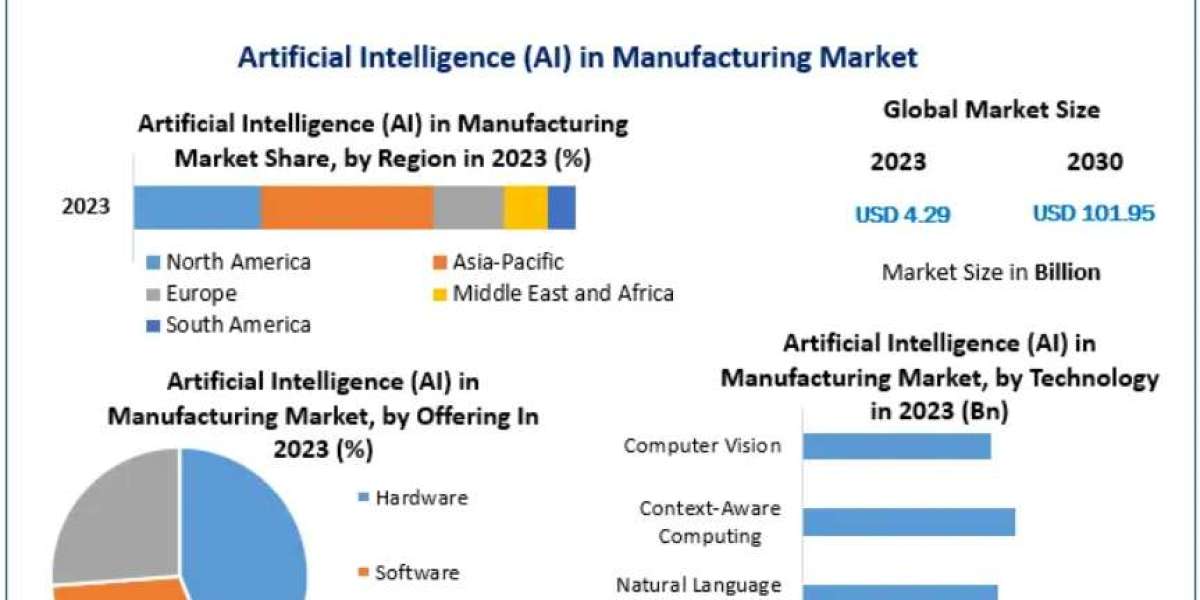

The Artificial Intelligence (AI) in Manufacturing Market is poised for unprecedented growth, transforming the way industries manage operations, optimize production, and enhance efficiency. Valued at USD 4.29 billion in 2023, the market is projected to reach USD 101.95 billion by 2030, exhibiting a remarkable CAGR of 57.2% over the forecast period. The rapid adoption of AI technologies is reshaping manufacturing, driving cost savings, predictive maintenance, and smart production systems across multiple industries.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/63530/

Transforming Manufacturing with AI

AI is revolutionizing manufacturing by enabling machines and systems to analyze vast volumes of data, predict outcomes, and automate complex processes. From predictive maintenance to quality control, AI applications reduce unplanned downtime, improve operational efficiency, and enhance product quality. With the rise of Industry 4.0, connected devices, IoT sensors, and cloud-based analytics are generating enormous volumes of industrial data, creating opportunities for AI to optimize manufacturing workflows.

By 2023, approximately 1.8 megabytes of new data were generated every second, and this number is projected to grow at an annual rate of 40% over the next decade. This explosion of data fuels the need for AI-driven analytics and intelligent automation in factories, enabling real-time decision-making and predictive insights.

Market Drivers

Operational Efficiency and Cost Reduction:

Unplanned equipment downtime and production delays result in significant financial losses for manufacturers. AI-powered predictive maintenance and machinery inspection solutions help prevent failures, reduce repair costs, and optimize production schedules.

Rising Adoption of Industry 4.0 Technologies:

Manufacturers are increasingly integrating AI with IoT, robotics, and cloud computing to create smart factories. This combination enables automated material handling, adaptive production planning, and real-time quality monitoring.

Data-Driven Decision Making:

AI leverages advanced analytics, machine learning, computer vision, and natural language processing to provide actionable insights. These technologies enhance process efficiency, improve safety, and enable predictive operational planning.

Market Restraints

Despite the significant potential, AI adoption in manufacturing faces challenges:

Complex Industrial Data: The heterogeneous and unstructured nature of manufacturing data complicates AI implementation.

Skill Shortages: Many factories lack professionals skilled in both AI technology and industrial processes.

High Implementation Costs: Advanced AI hardware, software, and integration require substantial investment, limiting adoption for small and medium enterprises.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/63530/

Market Opportunities

Autonomous Manufacturing and Smart Factories:

AI presents opportunities to create fully autonomous factories with minimal human intervention. From robotic process automation to intelligent material movement, AI-driven systems are enhancing productivity, reducing errors, and enabling rapid scalability.

Sector-Specific Innovations:

The automobile sector dominates AI adoption due to increasing demand for autonomous vehicles, advanced quality control systems, and predictive maintenance solutions. Similarly, semiconductor, pharmaceuticals, and heavy machinery industries are leveraging AI to optimize complex manufacturing operations.

Segment Analysis

By Offering:

Hardware: AI-enabled machinery, sensors, and computing devices driving automation.

Software: Machine learning platforms, context-aware computing, computer vision, and NLP applications.

Services: Integration, consulting, and maintenance support for AI solutions.

By Technology:

Machine Learning

Natural Language Processing (NLP)

Context-Aware Computing

Computer Vision

By Application:

Predictive Maintenance & Machinery Inspection

Production Planning

Material Movement

Quality Control

Cybersecurity

Industrial Robots

Reclamation

Regional Insights

Asia Pacific leads the AI in Manufacturing market with over 46% market share in 2023, supported by advanced manufacturing hubs in China, Japan, and South Korea. The region benefits from early adoption of Industry 4.0 technologies and significant investment in smart manufacturing infrastructure.

North America and Europe are witnessing robust adoption driven by technological innovation, industrial automation, and the presence of leading AI solution providers.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/63530/

Key Market Players

Major players dominating the AI in Manufacturing market include:

Nvidia

Intel

IBM

Siemens

General Electric (GE)

Google

Microsoft

Rockwell Automation

SAP

Cisco Systems

Mitsubishi Electric

Vicarious

Rethink Robotics

SparkCognition Inc.

Ubtech Robotics

These companies focus on high-performance AI solutions, industrial automation, predictive analytics, and smart factory platforms, positioning themselves at the forefront of industrial AI innovation.

Future Outlook

The AI in Manufacturing market is on the path to transforming traditional manufacturing landscapes into intelligent, autonomous ecosystems. With continued investments in AI hardware, software, and services, along with the increasing demand for operational efficiency, predictive maintenance, and smart production processes, the market is set for remarkable growth. As manufacturers globally embrace AI-driven technologies, the sector is poised to redefine productivity, innovation, and competitiveness in the industrial world.