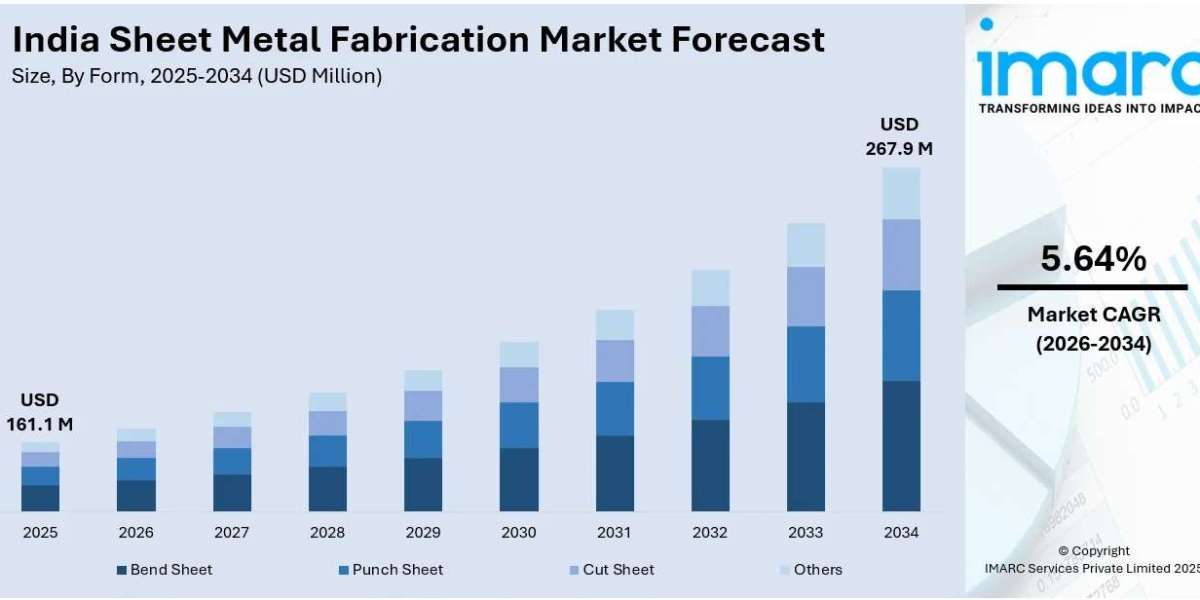

The India Sheet Metal Fabrication Market reached USD 161.1 Million in 2025 and is forecast to reach USD 267.9 Million by 2034, growing at a CAGR of 5.64% during 2026-2034. Growth is propelled by expanding demand in automotive, construction, and industrial sectors, alongside urbanization, infrastructure development, automation adoption, and supportive government policies. Advancements in CNC machining, laser cutting, and robotic welding further improve efficiency and accuracy in fabrication processes. For more details, visit the India Sheet Metal Fabrication Market report page. The report presents a thorough review featuring the India Sheet Metal Fabrication Market Analysis, share, trends, and research of the industry.

STUDY ASSUMPTION YEARS

- Base Year: 2025

- Historical Year/Period: 2020-2025

- Forecast Year/Period: 2026-2034

INDIA SHEET METAL FABRICATION MARKET KEY TAKEAWAYS

- Current Market Size: USD 161.1 Million in 2025

- CAGR: 5.64%

- Forecast Period: 2026-2034

- Increasing adoption of advanced fabrication technologies such as laser cutting, CNC machining, and automated forming is enhancing productivity and reducing material waste.

- Urbanization and infrastructure projects are driving demand for bespoke metal components.

- Government initiatives like "Make in India" and PLI schemes are encouraging local manufacturing and investments in fabrication technology.

- Rising demand from automotive, aerospace, electronics, and construction industries is expanding market opportunities.

- Export opportunities are growing as multinational corporations seek reliable fabrication partners in India.

Sample Request Link: https://www.imarcgroup.com/india-sheet-metal-fabrication-market/requestsample

MARKET TRENDS

The market is witnessing rising adoption of advanced fabrication technologies, driven by the demand for accuracy, efficiency, and automation. Companies are increasingly utilizing laser cutting, CNC machining, and automated forming solutions to improve productivity and minimize waste. For instance, the BLECH India event in May 2024, hosting over 250 exhibitors and 15,000 visitors, underscores the growing significance of laser cutting and automation in sheet metal fabrication.

Automation is rapidly advancing in the sector with firms integrating robotics and IoT-based solutions to automate fabrication processes. This shift promotes sustainable practices, such as the use of energy-efficient equipment and optimized material usage. The emergence of smart factories and automated production lines is setting the stage for the future growth of India's sheet metal industry, enhancing global competitiveness.

The market's growth is also fueled by government policies promoting local manufacturing and industrial expansion. These policies encourage the adoption of innovative fabrication technologies, helping sectors like automotive, aerospace, and construction improve product quality and operational efficiency. Such trends signal a robust move toward a high-tech and sustainable fabrication landscape.

MARKET GROWTH FACTORS

The increasing demand from automotive, industrial, and construction sectors is a key growth driver. Urbanization and major infrastructure projects are boosting the need for custom metal components. The automotive industry's use of lightweight materials for fuel efficiency has led to higher incorporation of fabricated sheet metals in vehicle manufacturing.

Government initiatives such as the Production Linked Incentive (PLI) schemes and Make in India program are facilitating local manufacturing growth and attracting investments in advanced fabrication technologies. These initiatives support the adoption of robotic welding, laser cutting, and CNC automation, enhancing productivity and precision.

The precision needs of consumer goods and electronics sectors are driving the demand for metal frames and enclosures. With multinational companies seeking dependable fabrication partners in India, export potential is expanding. Integration of automation, AI-based quality control, and material innovations further positions India as a cost-effective, skilled labor hub in the global sheet metal fabrication arena.

MARKET SEGMENTATION

Form:

- Bend Sheet

- Punch Sheet

- Cut Sheet

- Others

Each form segment represents specific types of sheet metal fabrication processes used in various applications, providing diverse product offerings.

Material:

- Silver

- Aluminum

- Others

Material segments categorize the metal types used in fabrication, influencing product properties and industry uses.

End Use:

- Industrial Machinery

- Construction

- Aerospace and Defence

- Automotive

- Electronics

- Telecommunication

- Others

These segments represent the key industries that utilize sheet metal fabrications tailored to their operational requirements.

REGIONAL INSIGHTS

The report covers North India, South India, East India, and West India regions. The source does not explicitly highlight a dominant region or specific statistics such as market share or CAGR by region.

Summary: Not provided in source.

RECENT DEVELOPMENTS & NEWS

In November 2024, Raghu Vamsi Group invested INR 300 Crore to establish a precision manufacturing facility in Hyderabad. This expansion enhances India's aerospace and defense supply chain through advanced CNC machining and sheet metal fabrication, boosting competitiveness in high-precision components.

In September 2024, SLTL Group showcased its 12kW Fiber Laser Cutting Machine at the Rajkot Machine Tools Show held on September 25-28. This advancement in laser technology improves precision, reduces material waste, and accelerates automation, enhancing manufacturing efficiency in India's sheet metal sector.

KEY PLAYERS

- Raghu Vamsi Group

- SLTL Group

CUSTOMIZATION NOTE

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

ABOUT US

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

CONTACT US

IMARC Group,

134 N 4th St. Brooklyn, NY 11249, USA,

Email: [email protected],

Tel No: (D) +91-120-433-0800,

United States: +1-201-971-6302