IMARC Group, a leading market research company, has recently releases a report titled “Plastic Processing Machinery Market Size, Share, Trends and Forecast by Product Type, Plastic Type, End-Use Industry, and Region, 2025-2033.” The study provides a detailed analysis of the industry, including the global plastic processing machinery market size, share, trends and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Plastic Processing Machinery Market Highlights:

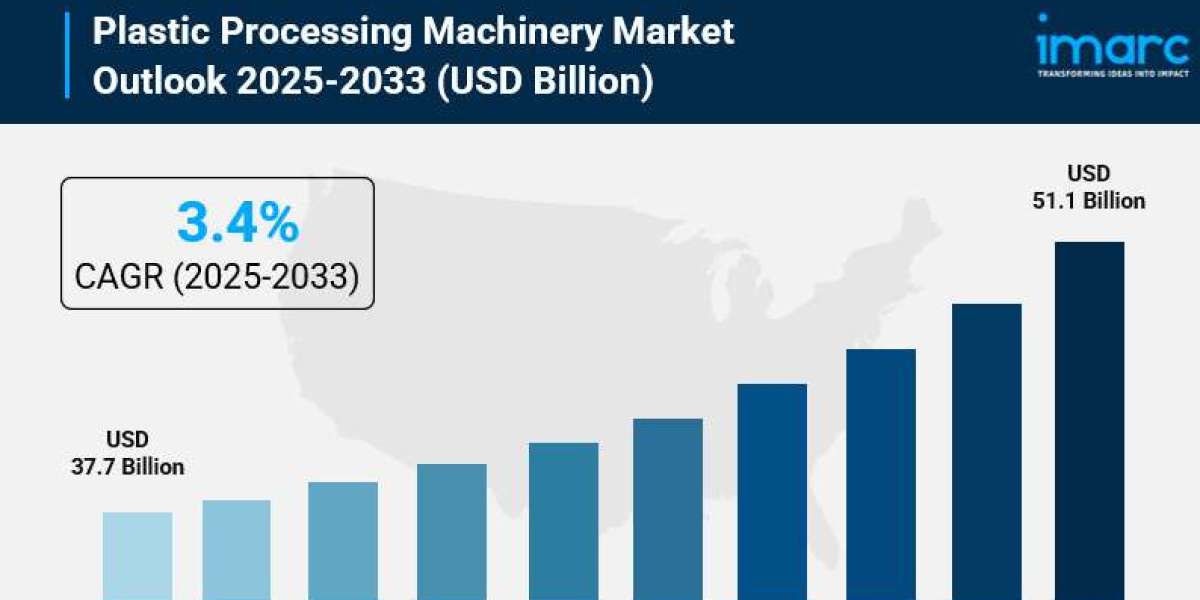

- Plastic Processing Machinery Market Size: Valued at USD 37.7 Billion in 2024.

- Plastic Processing Machinery Market Forecast: The market is expected to reach USD 51.1 billion by 2033, exhibiting a growth rate (CAGR) of 3.4% during 2025-2033.

- Market Growth: The plastic processing machinery market is projected to grow significantly due to increased demand for plastic products across various industries.

- Key Drivers: Growth is driven by advancements in technology, rising production of plastics, and increasing applications in packaging, automotive, and consumer goods.

- Types of Machinery: Includes injection molding machines, blow molding machines, extrusion machines, and thermoforming machines.

- Regional Insights: Asia-Pacific dominates the market, driven by high manufacturing capacities in countries like China and India.

- Sustainability Trends: Growing focus on sustainable practices is leading to the development of eco-friendly machinery and processes.

- Competitive Landscape: The market features several key players, including Engel, Arburg, and Husky Injection Molding Systems, focusing on innovation and strategic partnerships.

- Future Outlook: The market is expected to witness continuous growth with the integration of automation and smart technologies, enhancing efficiency and productivity.

Request for a sample copy of the report: https://www.imarcgroup.com/plastic-processing-machinery-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends and Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Industry Trends and Drivers:

- Automation and the Integration of Industry 4.0:

A primary market driver is due to the accelerating trend of Industry 4.0 technologies being integrated within the plastics manufacturing sector for automation. Machinery of a more advanced type is just but an investment by companies from all over the globe toward improvement of production efficiency. Better quality control is ensured as reliance on only manual labor decreases. Modern plastic processing equipment such as injection molding and extrusion machines does now feature integrated robotics as well as advanced sensors with real-time data analytics capabilities. This lets us predict maintenance and remotely diagnose problems while optimizing production cycles. When companies adopt the Industrial Internet of Things (IIoT), machines through centralized management systems communicate smoothly, which greatly increases overall equipment effectiveness (OEE). Smart factories are important for manufacturers to stay competitive specifically in high-wage economies because this shift minimizes waste, maximizes throughput, and achieves precision that is needed by complex, high-value plastic components within automotive and medical devices sectors.

- Growing Demand from Packaging and Automotive Industries:

Since packaging along with automotive are two key end-use sectors under sustained and strong demand, they propel the plastic processing machinery market. The packaging industry gains momentum due to global population growth, urbanization, and e-commerce expansion. The industry finds that massive volumes of plastic containers with films in addition to bottles are required. This demand requires investment. Firms should invest ceaselessly in rapid, large-capacity equipment. The automotive sector is adopting lightweight plastic components. This adoption seeks to work for the improving of fuel efficiency as well as reducing vehicle weight, especially within electric vehicles (EVs). Complex plastic parts both interior and exterior need advanced machines. The machines are able to perform with high-precision injection molding. Manufacturers are always seeking after machinery for a processing of specialty plastics and of composites meeting those stringent safety and durability standards. Consistent need for advanced plastic forming machinery is certain, because faster process speeds, larger output amounts, and exact parts are required within these two huge, expanding sectors.

- The Circular Economy and Demand for Sustainable Processing:

The third critical driver focuses globally on sustainability along with the circular economy that reshapes fundamentally design with functionality in plastic processing machinery. Environmental issues with rules (such as single-use plastic bans and recycled content orders) force equipment makers to adapt. Demand for machinery so as to handle recycled as well as bio-based plastics, which often have different thermal and rheological properties than virgin materials, is driven through this trend. Innovators develop machines for using energy in a more efficient way, systems closing loops so as to minimize waste output, and equipment processing plastics that are highly difficult to recycle. Chemical recycling machinery and improved sorting technologies currently show a market increase. Industry's shift from a linear model toward a circular one is compelling capital expenditure on advanced processing machinery. It can assist in the using of post-consumer resin (PCR) and other sustainable materials for maintaining product quality.

Plastic Processing Machinery Market Report Segmentation:

Breakup by Product Type:

- Blow Molding Machinery

- Compression Molding Machinery

- Extrusion Molding Machinery

- Injection Molding Machinery

- Rotational Molding Machinery

- Others

Breakup by Plastic Type:

- Polypropylene (PP)

- Polyethylene (PE)

- Polyurethane (PUR)

- Polyvinyl Chloride (PVC)

- Polyethylene Terephthalate (PET)

- Polystyrene (PS)

- Others

Breakup by End Use Industry:

- Packaging Industry

- Construction Industry

- Automotive Industry

- Electronic and Electrical Industry

- Agriculture Industry

- Others

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Who are the key players operating in the industry?

The report covers the major market players including:

- Arburg GmbH

- Cosmos Machinery

- Haitian Plastics Machinery Group Co. Ltd.

- Husky Injection Molding Systems

- Japan Steel Works Ltd.

- Milacron Holdings Corporation

- Niigata Machine Techno Company Ltd.

- Sumitomo Heavy Industries

- Toshiba Machine Co. Ltd.

Ask Analyst For Request Customization: https://www.imarcgroup.com/request?type=report&id=2026&flag=E

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services.

IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302