Magpie Sealing Technology Insight

Valve Packing Seals: Wear and Lubrication in Packing Seals

The service life and reliability of valve packing seals are strongly influenced by two critical factors: wear and lubrication. Understanding these aspects is essential for improving performance and reducing seal failures in demanding industrial environments.

What is Wear of Packing?

Friction-induced wear is one of the most common challenges in packing seals. During rotary or reciprocating motion, not only does the packing material degrade, but the shaft or valve stem in contact with the packing may also suffer abrasion.

The severity of wear depends on multiple factors, including:

The wear resistance of both the packing and shaft materials.

The shaft’s rotational or reciprocating speed.

The effectiveness of lubrication and cooling.

The quality of packing installation and adjustment.

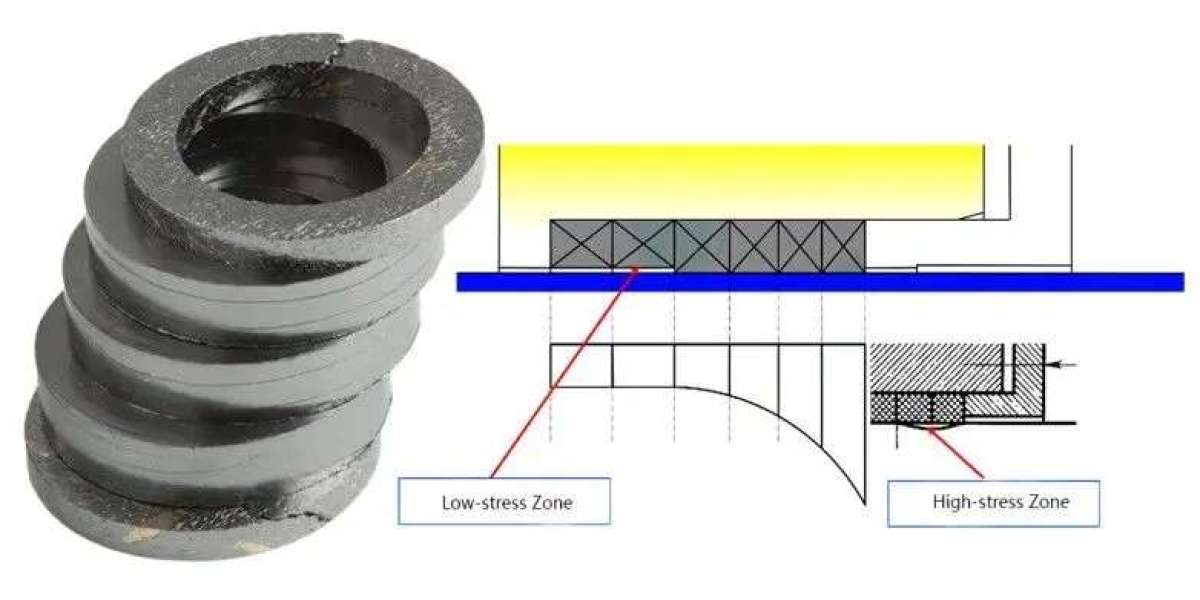

Due to the uneven axial distribution of radial contact stress, even correctly installed packing tends to wear faster at the gland area, with the wear rate decreasing inward. Poor installation can exacerbate this issue, creating high-stress zones that cause accelerated damage to both packing and shaft surfaces in a relatively short period.

Additionally, improper stem alignment—such as lack of coaxiality between the valve stem, stuffing box, and packing rings—can lead to uneven circumferential wear, which often becomes a major cause of packing seal failure.

Lubrication: Reducing Wear of Packing

Lubrication is a key factor in reducing wear and extending packing service life. Most braided packing materials are impregnated with self-lubricating, high-temperature-resistant lubricants. In some cases, lubrication can also come from external sources or even the process fluid itself.

Lubricants provide several critical functions:

Reducing friction between the packing and shaft.

Dissipating heat generated during operation.

Limiting thermal degradation of packing materials.

For extreme service conditions—such as high temperature, high pressure, or high shaft speed—forced lubrication and cooling may be required to maintain seal integrity.

In many valve stem packing assemblies, lantern rings (spacer rings) are installed within the packing set. These components enhance performance by:

Allowing lubricant injection.

Enabling leak detection and monitoring.

Providing a means to inject sealant in the event of excessive leakage, helping to restore sealing capacity.

Magpie’s Low-Emission Solutions

At Magpie Sealing, we are committed to delivering advanced low-leakage sealing systems that combine material science and precision engineering. Our solutions are designed to minimize fugitive emissions, extend service life, and enhance equipment reliability under the most demanding conditions.

If you have technical questions about sealing technologies or wish to explore tailored solutions for your applications, we welcome your comments and inquiries.

Thank you for reading this issue of Magpie Sealing Technology Insight. In our next edition, we will introduce the different types of sealing gaskets and their performance characteristics. Stay tuned!

It's important to know about Google SEO to help your website rank higher in search results.