The handheld design ensures that operators can maneuver the machine with ease, reaching tight corners and intricate areas that larger, stationary systems cannot access. This mobility does not come at the expense of performance. With carefully calibrated laser output, the handheld laser welding machine can produce consistent welds, ensuring structural integrity and minimal distortion. Its precision is particularly valuable for industries such as automotive manufacturing, aerospace, jewelry, and electronics, where even minor imperfections can have significant consequences.

Material versatility is another hallmark of handheld laser welding machines. They can work effectively with metals such as stainless steel, aluminum, copper, and even specialty alloys. This adaptability allows workshops and production facilities to reduce downtime caused by equipment changes and material-specific limitations. Furthermore, the concentrated energy of the laser minimizes the heat-affected zone, reducing the risk of damage to surrounding areas and preserving the original properties of the material being welded.

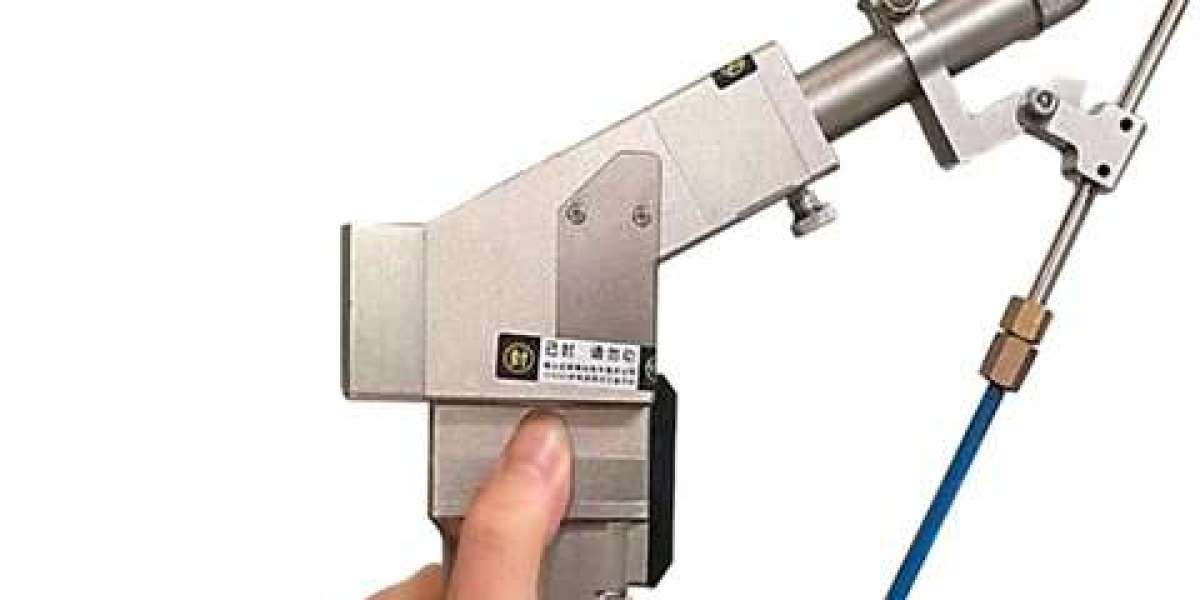

Safety and control are crucial considerations when operating a handheld laser welding machine. Operators can adjust parameters such as pulse duration, laser intensity, and welding speed to match the requirements of each task. This flexibility ensures precise control over the weld while maintaining consistent quality. In addition, the design of these machines often incorporates safety features to protect the user, such as shielding mechanisms and ergonomic handles that reduce operator fatigue during prolonged use.

Training and skill development play a significant role in maximizing the effectiveness of handheld laser welding machines. While the technology simplifies the welding process, achieving optimal results requires understanding the interaction between the laser and different metal surfaces. Professionals who master this technology can complete high-quality welds more quickly than with conventional methods, improving overall productivity. Additionally, the use of a handheld laser welding machine often reduces the need for post-weld finishing, which can further save time and resources in industrial settings.

Maintenance and calibration are straightforward but essential for ensuring the longevity and reliability of the machine. Routine inspections of the laser lens, cooling system, and electronic components prevent performance degradation and minimize unexpected downtime. When used consistently within recommended operating parameters, handheld laser welding machines provide years of dependable service, supporting the demands of continuous industrial operations.

Beyond its industrial applications, the handheld laser welding machine is also a valuable tool for specialized repair work. Automotive workshops use it for fixing engine components, exhaust systems, and body panels. Jewelry makers rely on its precision for intricate repairs and custom designs. Even in scientific laboratories, where small-scale metal fabrication is required, handheld laser welding machines offer a combination of accuracy and adaptability that traditional welding cannot match.

The future of welding technology is increasingly focused on compact, efficient, and precise solutions, making handheld laser welding machine a cornerstone of modern metalworking. Their ability to deliver strong, clean, and repeatable welds in a variety of settings highlights the evolution of laser-based tools in professional and industrial environments. Whether for large-scale manufacturing or delicate repair tasks, this technology is reshaping expectations for speed, quality, and reliability in metal joining processes.

In this guide, we will explain how the handheld laser welding machine works, its applications across industries, and best practices for achieving optimal performance in daily operations.