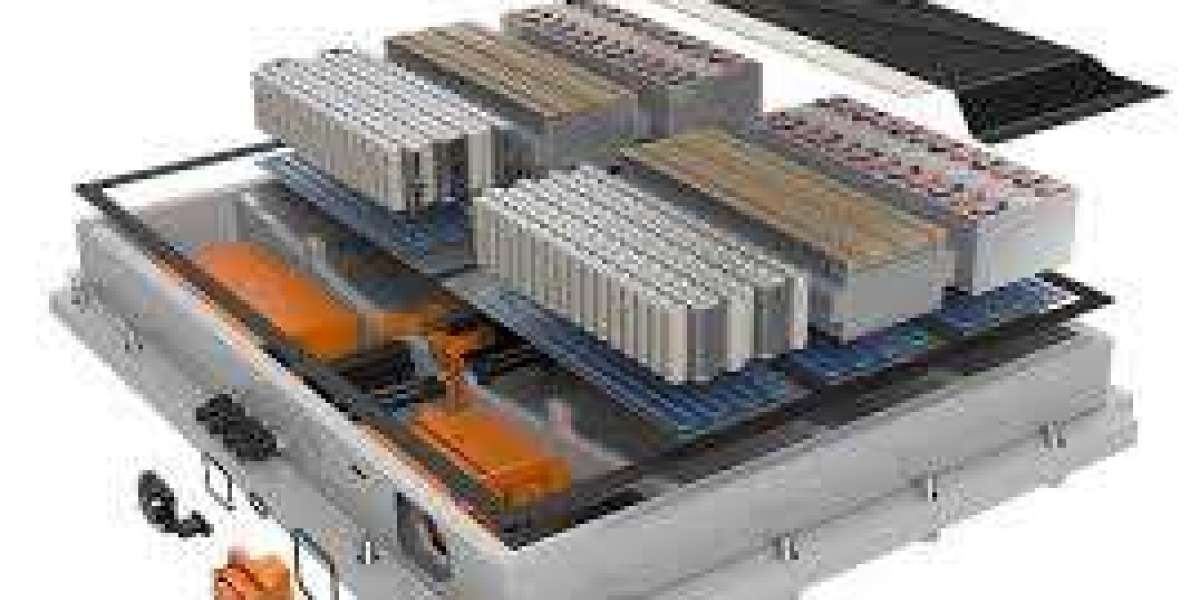

The electric vehicle battery adhesive market trends highlight the increasing importance of environmental compliance and low-emission adhesive formulations in modern electric vehicle batteries. Adhesives are essential for structural bonding, thermal management, and electrical insulation in battery systems. As governments enforce stricter emission and sustainability regulations, manufacturers are adopting low-VOC, eco-friendly adhesive solutions that reduce environmental impact while maintaining performance and reliability. These environmentally compliant adhesives support safe battery operation, improve durability, and extend battery life. Innovation in sustainable formulations ensures that electric vehicles meet both regulatory standards and consumer expectations for clean, high-performance transportation.

Market Drivers

Key drivers for market growth include stringent environmental regulations, rising consumer awareness, and increasing adoption of eco-friendly manufacturing practices. Adhesives that comply with low-emission standards help reduce VOCs and harmful chemical exposure, improving workplace safety and environmental sustainability. The growth of the electric vehicle market, coupled with demand for high-performance batteries, encourages the use of adhesives that meet both operational and environmental requirements. Advances in lithium-ion, solid-state, and hybrid battery technologies require adhesives capable of withstanding extreme thermal, mechanical, and electrical stresses while remaining environmentally compliant. Manufacturers are investing in research to develop adhesives that meet regulatory standards and ensure optimal battery performance.

Technological Innovations

Technological advancements focus on developing high-performance, environmentally friendly adhesives that meet regulatory and operational demands. Epoxy, silicone, and polyurethane-based adhesives provide structural integrity, thermal management, and electrical insulation. Low-VOC and recyclable adhesive formulations reduce environmental impact without compromising durability and reliability. Multifunctional adhesives integrate bonding, thermal, and electrical properties, reducing production complexity and improving efficiency. Automated application techniques enhance precision, minimize waste, and ensure consistent quality. Innovations in vibration-resistant, thermally conductive, and sustainable adhesives support safe, reliable, and environmentally compliant battery systems in modern electric vehicles.

Regional Insights

Regional adoption of environmentally compliant adhesives varies based on regulatory frameworks, EV production capacity, and sustainability initiatives. Europe leads in enforcing strict environmental standards, promoting low-emission adhesives. North America shows steady growth, driven by government incentives and growing awareness of eco-friendly practices. Asia-Pacific dominates EV production, particularly in China, Japan, and South Korea, where large-scale manufacturing encourages adoption of compliant adhesive solutions. Emerging markets are gradually integrating environmentally friendly adhesives to support sustainable EV production. Companies expanding R&D and production capabilities regionally can capitalize on regulatory trends and growing demand for low-emission, high-performance adhesives.

Market Challenges

Challenges in the market include balancing performance with environmental compliance, raw material availability, and cost considerations. High-performance adhesives must maintain durability, thermal stability, and electrical insulation while meeting low-emission standards. Developing solutions for lithium-ion, solid-state, and hybrid batteries requires specialized materials and extensive testing. Supply chain constraints and logistical issues can affect production efficiency. Companies must manage costs, sustainability, and regulatory compliance simultaneously. Overcoming these challenges is essential to delivering eco-friendly adhesive solutions that enhance battery safety, performance, and durability while adhering to environmental standards.

Competitive Landscape

The market is highly competitive, with global and regional players focusing on innovation, collaboration, and sustainability. Partnerships between adhesive manufacturers and automakers facilitate customized solutions for environmentally compliant battery systems. Mergers and acquisitions expand technological capabilities, production capacity, and market reach. Continuous innovation in low-VOC, high-performance, and multifunctional adhesives is critical to maintaining leadership. Companies offering durable, sustainable, and compliant adhesives gain a competitive advantage as global EV production increases. Effective strategies in R&D, production optimization, and environmental compliance allow companies to differentiate themselves in the growing EV battery adhesive market.

Applications Across EV Segments

Adhesives are applied across passenger cars, commercial vehicles, buses, and trucks. Passenger vehicles benefit from lightweight, environmentally friendly adhesives that improve battery efficiency, safety, and thermal performance. Commercial EVs and buses require adhesives that withstand vibrations, prolonged usage, and temperature fluctuations while remaining compliant with emission standards. Hybrid and plug-in hybrid vehicles rely on adhesives that provide structural integrity, thermal management, and electrical insulation. Tailored, eco-friendly adhesive solutions ensure consistent battery performance, reliability, and safety across all EV segments, supporting sustainable growth in the electric vehicle industry.

Future Outlook

The electric vehicle battery adhesive market is expected to grow steadily, driven by environmental compliance and demand for low-emission formulations. Advanced, multifunctional adhesives integrating bonding, thermal management, and electrical insulation will see broader adoption. Sustainable, low-VOC, and recyclable adhesives will become increasingly important to meet regulatory and environmental requirements. Investments in research, production optimization, and global distribution will ensure high-performance, environmentally compliant adhesives are available to meet the growing EV demand. Overall, the market presents significant opportunities for companies to develop innovative, sustainable adhesive solutions that enhance safety, performance, and environmental responsibility in electric vehicles worldwide.