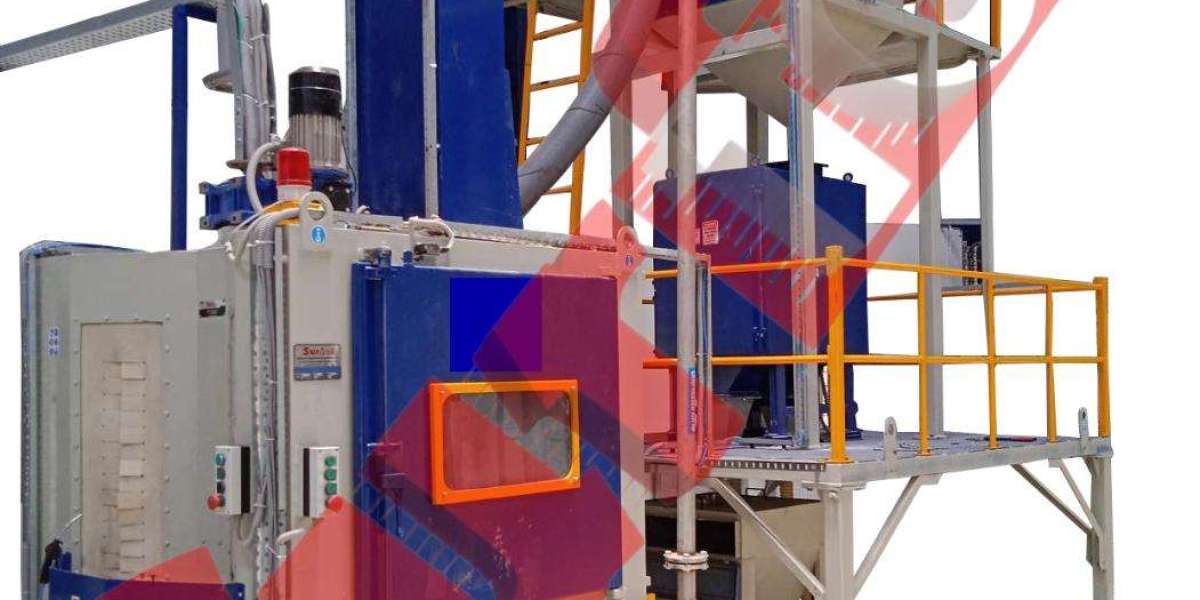

For manufacturers who need consistent fatigue life, superior surface integrity, and durable components, a shot peening machine is not a luxury—it’s a necessity. From aerospace turbine blades to automotive gears and heavy engineering springs, shot peening creates a controlled layer of compressive residual stress that delays crack initiation and dramatically improves service life. At sfecindia, we design and build shot peening machines that serve all industrial manufacturers—OEMs, Tier-1s, and precision job shops—by combining process accuracy, robust mechanicals, and easy digital traceability. Shot Blasting Machine, Shot Blasting Machine Manufacturers, Robotic Shot Peening Machine, shot peening machine, Robotic Shot Peening Machine Manufacturers , shot blasting machine manufacturers in india , shot peening machine manufacturers in india, shot peening machine manufacturers, Roll Etching Machine Manufacturers, Roll Texturing Machine Manufacturers, Shot blasting machine manufacturer, shot blasting machine manufacturers in asia, CNC Shot peening Machine

https://sfecindia.net/

https://sfecindia.net/shot-peening-machine.html

https://sfecindia.net/robotic-shot-peening-machine.html

https://sfecindia.net/roll-etching-machine.html

https://sfecindia.net/shot-peening-for-gears.html

What Is Shot Peening—and Why It Matters

Shot peening is a cold working process in which spherical media (steel, ceramic, or glass shots) bombard a surface at calibrated velocity and coverage. Each impact plastically deforms a tiny dimple; together these dimples generate compressive stress that counters tensile loads in service. The result is:

- Higher fatigue strength and longer component life

- Resistance to stress corrosion cracking and fretting

- Smoother micro-geometry where required and controlled roughness where beneficial

- Repeatable surface integrity for safety-critical parts

For all industrial manufacturers, a correctly specified shot peening machine standardizes this outcome shift after shift, part after part.

Industries and Components That Benefit

Aerospace: landing gear, turbine blades, discs, compressor wheels, fasteners

Automotive & EV: gears, shafts, springs, connecting rods, clutch hubs, transmission parts

Energy & Heavy Engineering: drill bits, blades, hubs, pipelines, powertrain couplings

Rail & Off-Highway: axles, springs, bogie components, track hardware

Medical & Tools: orthopedic implants (where allowed), cutting tools, dies, molds

Wherever cyclic loading exists, a shot peening machine can convert warranty risk into durable performance.

Core Machine Types from sfecindia

CNC Shot Peening Machines

Multi-axis programmable systems for complex geometries. Servo-controlled nozzles, real-time velocity feedback, and closed-loop air pressure deliver tight intensity bands on aero and transmission components.

Indexing Hanger Type Shot Peening Machines

Ideal for high-mix, medium-volume production. Multiple stations allow load/peen/unload in parallel, maximizing uptime. Great for springs, hooks, brackets, and structural parts.

Table/Turntable Shot Peening Machines

For heavier, disk-like parts—gears, rings, dies—needing uniform coverage. Programmable table speeds and nozzle angles ensure even exposure.

Robotic Shot Peening Cells

Six-axis robots handle intricate paths, maintain standoff distance, and automate part manipulation. Perfect for all industrial manufacturers chasing flexible automation and quick changeovers.

Air Peening vs. Wheel Peening

Air Peening: Compressed air propels media—best for precision control, lower intensity drift, and delicate parts.

Wheel Peening: Impeller wheels deliver high throughput for rugged parts at scale; lower operating costs per piece.

What Makes an sfecindia Shot Peening Machine Different

- Closed-Loop Intensity Control: Live monitoring of air pressure, media flow, and nozzle velocity stabilizes Almen intensity across shifts.

- Media Flow Precision: Mass-flow controllers, vibratory classifiers, and sieves maintain shot size distribution for repeatable results.

- Coverage Assurance: Vision-assisted or algorithmic coverage models reduce over-peening and cut cycle times.

- Dust & Containment Engineering: Efficient reclamation, cyclone separators, and cartridge filtration protect operators and parts.

- Operator-First Design: Intuitive HMI, recipe libraries, alarms, and guided setup minimize training time.

- Traceability & Analytics: Batch logs, intensity records, coverage metrics, and maintenance counters simplify audits and PPAPs.

- Built-for-India, Built-for-Export: Rugged frames, quality components, and serviceability tuned for long life and global standards.

Key Specifications to Get Right

When shortlisting a shot peening machine, align specs to your parts and standards:

Almen Intensity Range: Ensure your required N/A/C strip ranges are achievable with headroom.

Media Type & Size: Steel (S), conditioned cut wire (CCW), ceramic, or glass—matched to base material and finish targets.

Nozzle/Wheel Power: Determines intensity and coverage rates; balance with part temperature limits.

Fixturing & Motion: Rotary tables, multi-spindle indexers, or robots for line-of-fire accuracy and throughput.

Process Monitoring: Flow meters, pressure transducers, temperature sensors, strip holders, and vision options.

Automation Level: From semi-automatic to fully robotic with auto-loaders and in-cell inspection.

Footprint & Utilities: Air, power, and dust extraction sized for peak demand, not just averages.

Standards & Compliance

Critical sectors require documented compliance. sfecindia machines are engineered to help you meet commonly referenced specifications and best practices (e.g., Almen intensity verification, media conditioning, coverage validation, and periodic process audits). We provide calibration kits, SPC templates, and IQ/OQ/PQ support on request, helping all industrial manufacturers pass customer audits confidently.

Typical Workflow with an sfecindia Shot Peening Machine

Application Study: Parts, load conditions, and target fatigue life.

Media & Intensity Trials: Almen strips, saturation curves, and coverage studies to lock parameters.

Fixture Design: Repeatable orientation and minimal shadowing.

Recipe Build: Set pressures, flows, stand-off, angles, and traverse speeds.

Run & Validate: Log intensity, verify coverage, sample surface roughness, and archive batch data.

Scale & Optimize: Adjust nozzles, paths, or wheels for takt time; implement preventative maintenance.

ROI: Where the Payback Comes From

Reduced Field Failures: Fewer returns and extended warranties

Longer Part Life: Pushes design margins or allows lightweighting

Process Repeatability: Less scrap and rework

Audit Readiness: Quicker approvals, faster customer onboarding

Lower Cost per Part: Especially with automated media recovery and high uptime

Even modest increases in fatigue life can repay a shot peening machine investment within months, especially on high-value or safety-critical components.

Why Choose sfecindia

Application Depth: Decades of shot finishing expertise—from blasting to precision peening—applied to your parts.

Customization: From compact cells to multi-robot lines, each shot peening machine is tailored to your geometry and standards.

Lifecycle Support: Installation, training, calibration tools, spares, and remote diagnostics.

Made for All Manufacturers: Whether you’re scaling an automotive line or running an aerospace repair shop, we size the solution to your takt, space, and quality goals.