In the domain of advanced materials science, the delineation between tensile strength vs yield strength is paramount for understanding the elastic-plastic transition and ultimate load-bearing capacity of structural and functional materials. These two parameters, though often considered in tandem, characterize fundamentally distinct mechanical phenomena that inform both design strategy and failure analysis.

Conceptual and Mechanistic Distinctions

The comparative evaluation of tensile strength vs yield strength requires a rigorous understanding of their mechanistic underpinnings:

Yield Strength (σy): Defines the critical stress at which permanent, plastic deformation initiates. Microscopically, this corresponds to the onset of dislocation glide or twinning within the crystal lattice.

Tensile Strength (σu): Represents the maximal stress the material can endure prior to fracture, often associated with necking and localized strain accumulation.

In essence, the study of tensile strength vs yield strength elucidates the bifurcation between recoverable elastic behavior and irreversible plastic deformation culminating in failure.

Stress-Strain Curve Analysis

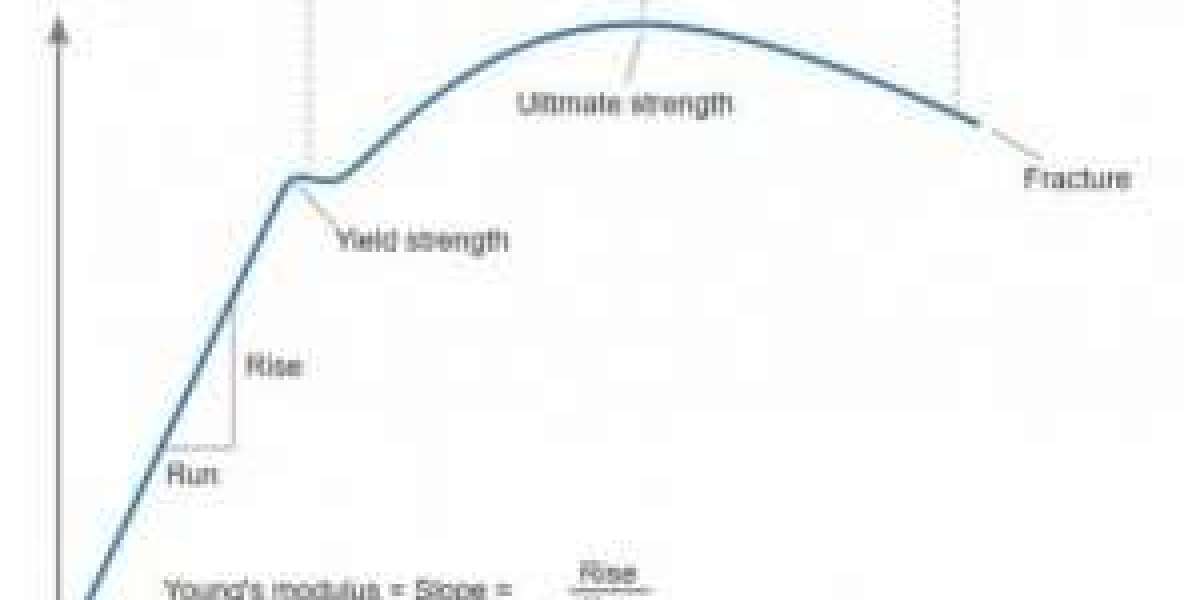

A detailed inspection of tensile strength vs yield strength is facilitated through stress-strain characterization:

Elastic Regime: Governed by Hooke’s law, where stress and strain are linearly proportional; deformation is reversible.

Yield Point: Marks the transition to plasticity; the magnitude of applied stress at this juncture defines yield strength.

Strain Hardening Region: Plastic deformation induces dislocation multiplication and interaction, temporarily increasing material resistance to further deformation.

Ultimate Tensile Stress (UTS): The apex of the stress-strain curve, representing tensile strength; beyond this point, localized necking precedes catastrophic fracture.

The ratio of tensile strength vs yield strength is indicative of ductility, toughness, and work-hardening capacity, crucial parameters in advanced engineering applications.

Microstructural Determinants

The intricate interplay of microstructural features governs tensile strength vs yield strength:

Grain Boundaries: Serve as dislocation barriers, with finer grains enhancing yield and tensile strength (Hall-Petch effect).

Phase Composition: Multi-phase alloys (e.g., martensitic-austenitic steels) exhibit complex stress redistribution affecting both yield and ultimate strength.

Precipitation Hardening: Nanoscale precipitates impede dislocation motion, selectively elevating yield strength.

Work Hardening and Cold Working: Increases dislocation density, modifying the tensile strength vs yield strength ratio by enhancing yield more than ultimate tensile strength.

Temperature and Strain Rate Sensitivity: Elevated temperatures reduce σy and σu due to increased atomic mobility, whereas high strain rates may induce dynamic strengthening phenomena.

Engineering Implications

A sophisticated understanding of tensile strength vs yield strength is critical in high-performance design:

Structural Components: Yield strength governs elastic safety limits, while tensile strength ensures ultimate failure is avoided.

Aerospace Engineering: Material selection leverages high tensile-to-yield ratios for fatigue resistance and impact tolerance.

Automotive Safety: Crashworthiness depends on predictable plastic deformation beyond yield without premature tensile failure.

Pressure Vessels and High-Temperature Applications: Elevated yield strength ensures dimensional stability under operating loads, while tensile strength dictates burst limits.

Quantitative Material Comparison

| Material | σy (MPa) | σu (MPa) | Ductility & Microstructural Notes |

|---|---|---|---|

| Mild Steel | 250 | 450 | High ductility, extensive plastic flow |

| Maraging Steel | 1100 | 1400 | Low ductility, high yield, precipitation-hardened |

| Aluminum 7075-T6 | 503 | 572 | Moderate ductility, aerospace applications |

| Ti-6Al-4V | 880 | 950 | Excellent strength-to-weight, moderate ductility |

| Stainless Steel 316 | 290 | 580 | Corrosion resistant, high tensile/yield ratio |

Design Optimization Considerations

Analyzing tensile strength vs yield strength enables:

Determination of factor of safety (FoS) in structural and mechanical designs:

FoS=Yield StrengthApplied StressFoS = \frac{\text{Yield Strength}}{\text{Applied Stress}}

Prediction of elastic and plastic deformation regimes under service loads.

Assessment of fatigue life, impact resistance, and ductility in cyclic loading scenarios.

Microstructural engineering through alloying, heat treatment, and work hardening to tailor σy and σu for specific applications.

Conclusion

The rigorous evaluation of tensile strength vs yield strength constitutes a cornerstone of metallurgical engineering, combining microstructural insight, mechanical testing, and thermomechanical considerations. Yield strength delineates the boundary of recoverable deformation, whereas tensile strength quantifies ultimate failure limits. Mastery of tensile strength vs yield strength enables engineers to design materials and components that harmonize performance, safety, and durability in complex operational environments.