At the heart of every robust machine is a powerful engine, and for heavy equipment like the Liebherr excavator, the engine's reliability is paramount. While much attention is paid to major components like the fuel pump or pistons, the humble thermostat is one of the most critical parts in ensuring the engine’s long-term health. The thermostat acts as the "conductor" of the engine cooling system, regulating temperature to ensure the engine operates in its optimal range. This article will focus on the often-overlooked but crucial role of thermostats in Liebherr engines, explaining how a small component is vital for fuel efficiency, performance, and longevity. We will cover the symptoms of a failing thermostat, the consequences of ignoring the problem, and provide a clear guide on proper diagnostics and replacement using genuine Liebherr parts.

How a Thermostat Works: The Conductor of the Cooling System

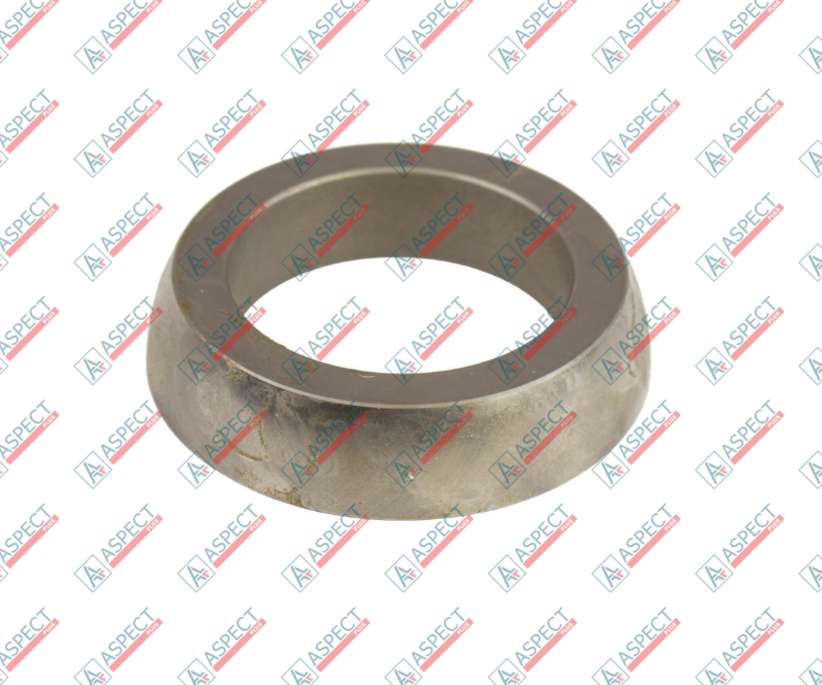

The primary function of a thermostat is to maintain the engine's operating temperature within a very specific and efficient range. It is a simple, spring-loaded valve that contains a wax pellet.

- Warm-Up Phase: When the engine is cold, the thermostat remains closed, preventing coolant from circulating to the radiator. This allows the engine to warm up quickly, reducing wear and improving fuel efficiency.

- Operating Phase: As the engine reaches its designated operating temperature, the wax pellet melts and expands, pushing the valve open. This allows coolant to flow to the radiator, where it dissipates heat.

- Regulation: The thermostat continuously adjusts its opening and closing, precisely regulating the amount of coolant flowing to the radiator to maintain a stable and ideal operating temperature.

This continuous regulation is vital for Liebherr engines, which are designed for optimal performance at a specific temperature.

Symptoms of a Failing Thermostat

A faulty thermostat can lead to two main problems: engine overheating or engine overcooling. Both are detrimental to the engine's health.

- Engine Overheating: This is the most obvious symptom and occurs when the thermostat gets stuck in the closed position. The coolant cannot reach the radiator, and the engine's temperature rises rapidly. This can lead to a damaged head gasket, warped cylinders, and catastrophic engine failure.

- Engine Overcooling: This occurs when the thermostat gets stuck open. The coolant circulates through the radiator constantly, preventing the engine from reaching its optimal operating temperature. This leads to poor fuel efficiency (as the fuel-air mixture is not properly vaporized), increased engine wear, and a loss of performance.

- Erratic Temperature Fluctuations: If the thermostat is failing intermittently, the temperature gauge may show wild swings from normal to hot and back again, which is a clear sign of an issue with the engine temperature control.

- Increased Fuel Consumption: An engine that runs too cool will consume more fuel to generate the same amount of power, a direct consequence of a faulty thermostat.

Why a Thermostat Fails and How to Replace It

Thermostats are simple devices, but they can fail due to material fatigue, corrosion, or contamination from the coolant itself. The failure of a thermostat is not just an inconvenience; it can have a direct impact on the most expensive component in your machine: the engine.

When a thermostat is suspected to be faulty, a simple diagnostics check can be performed. After the engine is cool, a visual inspection of the coolant level and the thermostat housing can reveal problems. However, a full test of its functionality often requires removing it and testing it in hot water to see if it opens at the correct temperature.

The Importance of a Quality Replacement:

When it's time for a thermostat replacement, using genuine Liebherr parts is essential. A non-genuine thermostat may be calibrated to the wrong temperature, or its material may not be durable enough to withstand the corrosive environment of the engine cooling system. A correct thermostat replacement guide will always recommend using genuine Liebherr parts because they are engineered to the exact specifications of the Liebherr engine, ensuring:

- Correct Temperature Control: The thermostat will open and close at the precise temperature required for the specific Liebherr engine model.

- Reliability and Longevity: The part is built to last, preventing a repeat failure and safeguarding the engine from damage.

Our company Aspect Plus offers a wide range of genuine Liebherr thermostats and other engine parts to help you maintain your equipment and ensure its long-term performance.

Conclusion

The thermostat is a critical, though inexpensive, component that plays a key role in the engine temperature control of Liebherr engines. Its proper function is vital for fuel efficiency, performance, and, most importantly, the longevity and reliability of your heavy equipment. By being vigilant for symptoms of a bad thermostat and committing to timely thermostat replacement with genuine Liebherr parts, you can prevent a minor issue from turning into a major engine catastrophe.

For expert diagnostics and a trusted source for all your Liebherr engine parts and cooling system needs, contact the specialists at Aspect Plus. We are here to help you protect your investment and ensure your Liebherr engine runs at its best.