Reliability in the Sachet Packaging Machine Market. Consistent access to quality materials directly impacts the production output, machine performance, and the competitiveness of manufacturers in both local and international markets. With increasing global supply chain complexities, geopolitical shifts, and environmental pressures, sourcing strategies have become a central point of discussion in the packaging machinery sector.

Importance of Raw Material Quality in Packaging Machinery

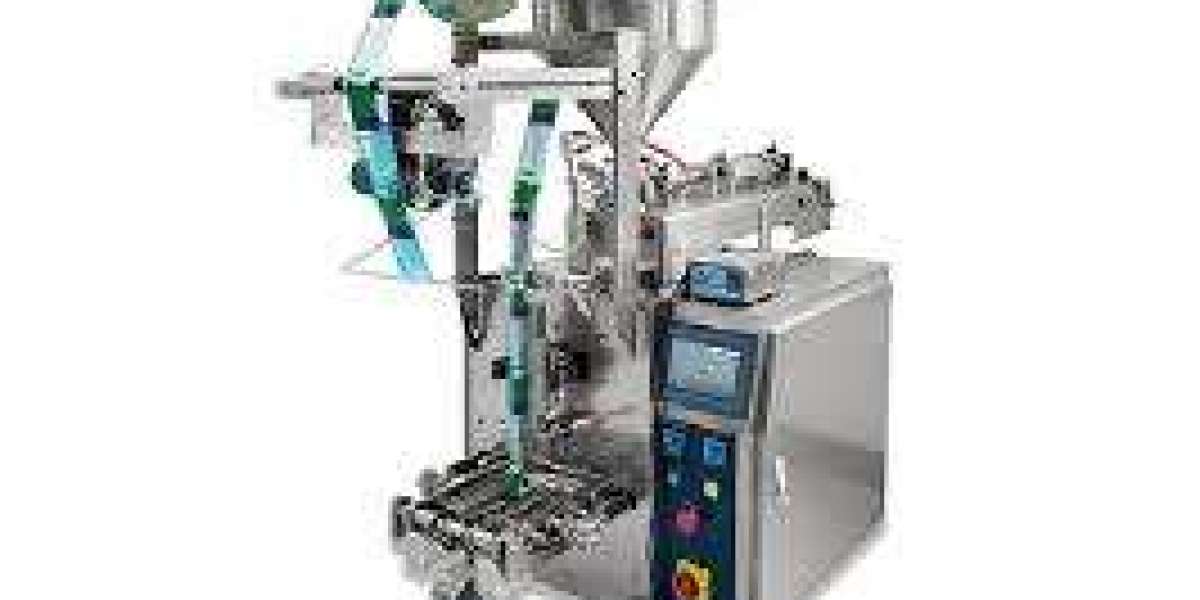

High-quality raw materials, such as stainless steel, aluminum, precision components, electrical systems, and automation controls, are essential for producing reliable sachet packaging machines. Poor-quality materials can result in machine breakdowns, reduced operational life, and increased maintenance costs. This, in turn, impacts delivery timelines, production capacity, and overall customer satisfaction.

Manufacturers are increasingly recognizing the need to establish strong supplier partnerships and maintain stringent quality checks to ensure that materials meet specific industry standards. This is especially important for sectors like pharmaceuticals and food packaging, where hygiene, safety, and durability are critical.

Global Supply Chain Challenges Affecting Raw Material Availability

The sachet packaging machine market is not immune to disruptions in global supply chains. Recent years have seen significant challenges, including:

Geopolitical Tensions: Trade disputes and sanctions can restrict the availability of essential raw materials.

Pandemic-Related Disruptions: COVID-19 highlighted vulnerabilities in international supply networks.

Transport and Logistics Bottlenecks: Delays at ports, rising freight costs, and container shortages have impacted delivery times.

Resource Scarcity: Increased competition for metals and electronic components has tightened supply.

These factors contribute to fluctuations in pricing and availability, making it more difficult for manufacturers to plan production schedules efficiently.

Cost Volatility and Its Impact on Profitability

The cost of raw materials has seen sharp fluctuations due to global market dynamics. Metals like stainless steel and aluminum, which are extensively used in manufacturing sachet packaging machines, can experience price increases due to rising energy costs or limited mining output.

Manufacturers must balance absorbing these costs against passing them on to customers. Over time, this volatility can significantly affect profitability, especially for small and mid-sized manufacturers who have less leverage in securing bulk discounts from suppliers.

Strategies for Securing Reliable Raw Material Supplies

To counter these challenges, many companies in the sachet packaging machine market are implementing proactive sourcing strategies:

Diversifying Supplier Networks: Relying on multiple suppliers from different geographic regions reduces dependency on any single source.

Long-Term Supplier Contracts: Securing agreements with fixed pricing over longer periods helps stabilize costs.

Local Sourcing Initiatives: Partnering with local suppliers can reduce transportation delays and mitigate geopolitical risks.

Inventory Management: Maintaining a strategic reserve of key materials ensures production continuity during disruptions.

These strategies, while sometimes requiring higher upfront investment, provide long-term stability and help maintain consistent production output.

Technological Solutions to Optimize Material Usage

In addition to sourcing strategies, technology plays a vital role in reducing reliance on scarce or expensive raw materials. Some innovations include:

Advanced Manufacturing Techniques: CNC machining and precision engineering minimize material wastage.

Automation and AI Integration: AI-powered systems can optimize design layouts for better material efficiency.

Alternative Materials: Exploring high-strength composites or recycled metals can lower dependency on traditional resources.

By leveraging these solutions, manufacturers can enhance production efficiency and reduce costs without compromising quality.

Regulatory and Sustainability Pressures

Environmental regulations are influencing how companies source and use raw materials. Many markets now require packaging machinery to be manufactured using eco-friendly processes and sustainable materials. This adds another layer of complexity to sourcing decisions, as manufacturers must balance cost, availability, and compliance requirements.

For example, the European Union’s sustainability policies encourage the use of recycled metals and the reduction of carbon footprints in manufacturing. Such regulations push manufacturers to adapt their sourcing practices to remain competitive in international markets.

Building Resilience in the Supply Chain

A resilient supply chain is one that can adapt quickly to unexpected disruptions. This requires:

Strong Supplier Relationships: Close communication with suppliers ensures early warnings about potential shortages.

Supply Chain Mapping: Understanding every step in the supply chain helps identify vulnerabilities.

Contingency Planning: Preparing alternative sourcing and production strategies in case of emergencies.

Companies that prioritize resilience are better positioned to maintain consistent production output, even in volatile market conditions.

Case Study: A Manufacturer’s Approach to Overcoming Sourcing Challenges

A leading sachet packaging machine manufacturer in Asia faced severe delays in receiving imported stainless steel components due to port congestion and freight cost surges. To address this, the company:

Partnered with local steel producers to source 40% of its requirements.

Invested in in-house component manufacturing capabilities.

Adopted lean manufacturing techniques to reduce wastage.

Within six months, production delays dropped by 60%, and the company reported improved profitability despite ongoing global supply challenges.

The Road Ahead for Raw Material Sourcing in the Industry

Looking forward, the sachet packaging machine market is expected to focus on sustainability, technology integration, and stronger supplier relationships. Companies that can combine cost efficiency with resilience will have a significant competitive advantage.

As global supply chains evolve, raw material sourcing strategies will play a decisive role in shaping the growth and stability of this sector. Continuous monitoring of market trends, investment in innovation, and proactive planning will be essential to ensure consistent production output in an increasingly competitive landscape.

Learn more...

https://www.pristinemarketinsights.com/sachet-packaging-machine-market-report