In today’s competitive market, speed, accuracy, and creativity are the driving forces behind successful product launches. Businesses can no longer rely solely on traditional design cycles; they need Prototyping tools that accelerate innovation, reduce risks, and ensure products meet customer expectations before hitting the shelves.

While technology evolves, so do the demands for smarter design solutions, and this is where Rapid Prototyping services and advanced Engineering prototype techniques step in to bridge the gap between ideas and reality.

The Role of Prototyping Tools in Product Innovation

Prototyping tools are the backbone of modern product development. They help transform raw concepts into tangible, testable models that bring clarity to design intent. Instead of relying on guesswork, businesses can visualize, adjust, and perfect their designs before committing to full-scale production.

With the right Prototyping tools, companies can:

Identify flaws early in the design stage

Improve product ergonomics and usability

Communicate ideas clearly with stakeholders and clients

Reduce manufacturing costs by eliminating unnecessary iterations

From Concept to Reality: How Rapid Prototyping Services Work

Rapid Prototyping services use advanced fabrication methods—such as 3D printing, CNC machining, and laser cutting—to quickly produce physical models from digital designs. This drastically reduces lead times compared to traditional manufacturing.

2.1 Speed Meets Precision

In product design, time is money. Rapid Prototyping services empower companies to go from a CAD file to a fully functional model in a fraction of the time it would take with conventional processes.

2.2 Multiple Iterations Without High Costs

By pairing Prototyping tools with these services, teams can create multiple design variations for testing without a huge financial burden. This freedom encourages creativity and exploration.

Why Prototyping Tools Are Essential for Engineering Prototypes

An Engineering prototype is more than just a visual model—it’s a working representation of a product’s functionality. It allows engineers to test structural integrity, performance, and manufacturability before mass production.

Prototyping tools make it possible to:

Simulate real-world usage scenarios

Test material durability and load capacity

Ensure compliance with safety and industry standards

By integrating these tools with modern design workflows, engineers can create reliable Engineering prototype models that minimize costly errors later.

Types of Prototyping Tools for Every Stage of Development

Different stages of product development require different types of Prototyping tools. Let’s explore the most commonly used categories:

4.1 Digital Prototyping Tools

Software-based tools like CAD (Computer-Aided Design) and simulation software allow teams to design, visualize, and test products virtually before physical manufacturing.

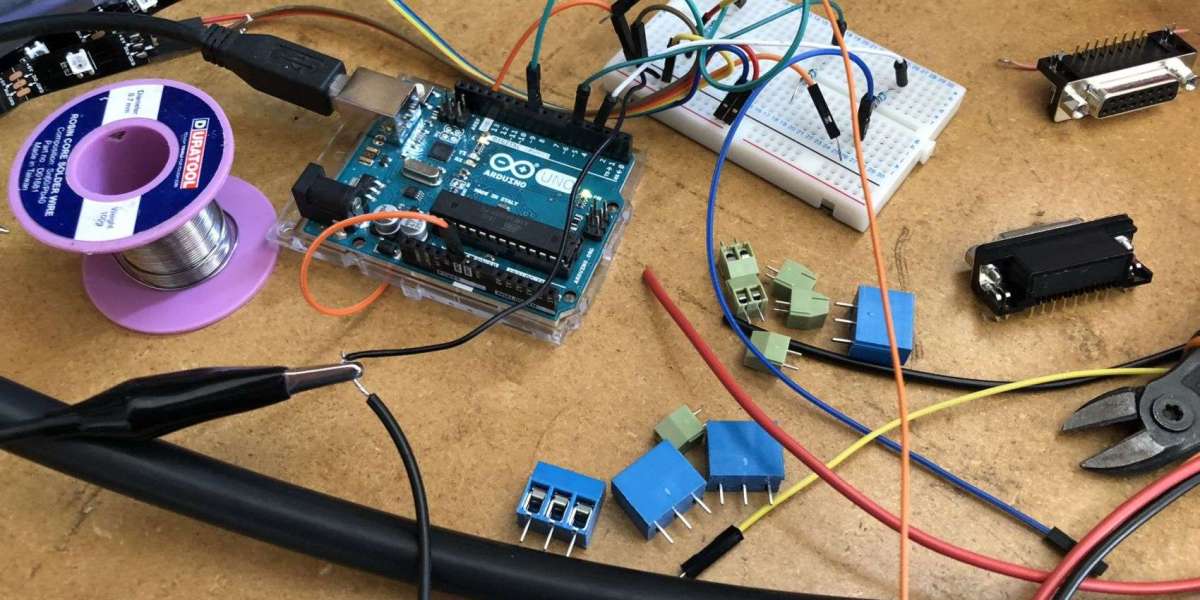

4.2 Physical Prototyping Tools

Equipment such as 3D printers, CNC machines, and molding systems bring digital models into the physical world, allowing hands-on testing.

4.3 Hybrid Prototyping Tools

A combination of digital and physical tools can accelerate the design cycle, enabling simultaneous visualization and real-world testing.

The Impact of Prototyping Tools on Cost and Efficiency

When businesses invest in Prototyping tools, they save more than just time. They also:

Reduce waste by avoiding mass production errors

Lower labor costs by catching design flaws early

Shorten the time-to-market for new products

Rapid Prototyping services amplify these benefits by providing quick turnaround times and professional-quality prototypes, even for complex designs.

Using Prototyping Tools for Cross-Functional Collaboration

Prototyping tools don’t just benefit engineers—they empower marketing teams, sales teams, and executives as well. By having a tangible model in hand, all departments can align on the vision of the final product.

With Rapid Prototyping services, cross-functional teams can review prototypes together, make quick adjustments, and ensure the product appeals to both functional and aesthetic requirements.

Real-World Applications of Engineering Prototypes

Industries across the globe rely on Engineering prototype models for different purposes:

Automotive: Testing aerodynamics and safety features

Consumer electronics: Validating circuit board layouts and housing designs

Medical devices: Ensuring precision in life-saving instruments

The use of advanced Prototyping tools ensures these prototypes are built with accuracy, enabling faster certification and regulatory approval.

How to Choose the Right Prototyping Tools for Your Business

When selecting Prototyping tools, consider:

Project Complexity: High-detail designs may require CNC machining or resin-based 3D printing.

Material Requirements: Different tools work with different materials—plastic, metal, or composites.

Budget and Timeline: Some methods are more cost-effective for short runs, while others are better for large-scale prototyping.

Partnering with a provider offering Rapid Prototyping services can help you access a variety of tools without the upfront investment.

The Future of Prototyping: AI, Automation, and Sustainability

Prototyping tools are evolving with the rise of artificial intelligence, automation, and eco-friendly materials. In the near future, we can expect:

AI-driven design optimizations

Fully automated prototyping workflows

Sustainable materials that reduce environmental impact

These innovations will make Engineering prototype development even faster, more accurate, and more responsible.

Conclusion:

The path from concept to final product has never been more streamlined, thanks to the power of Prototyping tools. From early sketches to fully functional Engineering prototype models, these tools allow teams to innovate faster, smarter, and with greater precision.

Whether it’s through in-house equipment or specialized Rapid Prototyping services, businesses that embrace these technologies position themselves ahead of the competition. By investing in the right Prototyping tools, you’re not just making a product—you’re shaping the future of innovation.