Industry Key Highlights

According to TechSci Research report, “India Industrial Automation Market - By Region, Competition Forecast & Opportunities 2030F”, India Industrial Automation Market was valued at USD 16.2 billion in 2024 and is expected to reach at USD 37.42 Billion in 2030 and project robust growth in the forecast period with a CAGR of 14.8% through 2030.

Request For Sample Copy of Report For More Detailed Market insight: https://www.techsciresearch.com/sample-report.aspx?cid=15147#requestform

The surge is largely attributed to the nation’s accelerated transition toward digital manufacturing, propelled by the growing influence of Industry 4.0. Government initiatives such as "Make in India," coupled with the rising need for increased productivity, operational efficiency, and cost reduction across industries, are fostering a vibrant ecosystem for automation solutions.

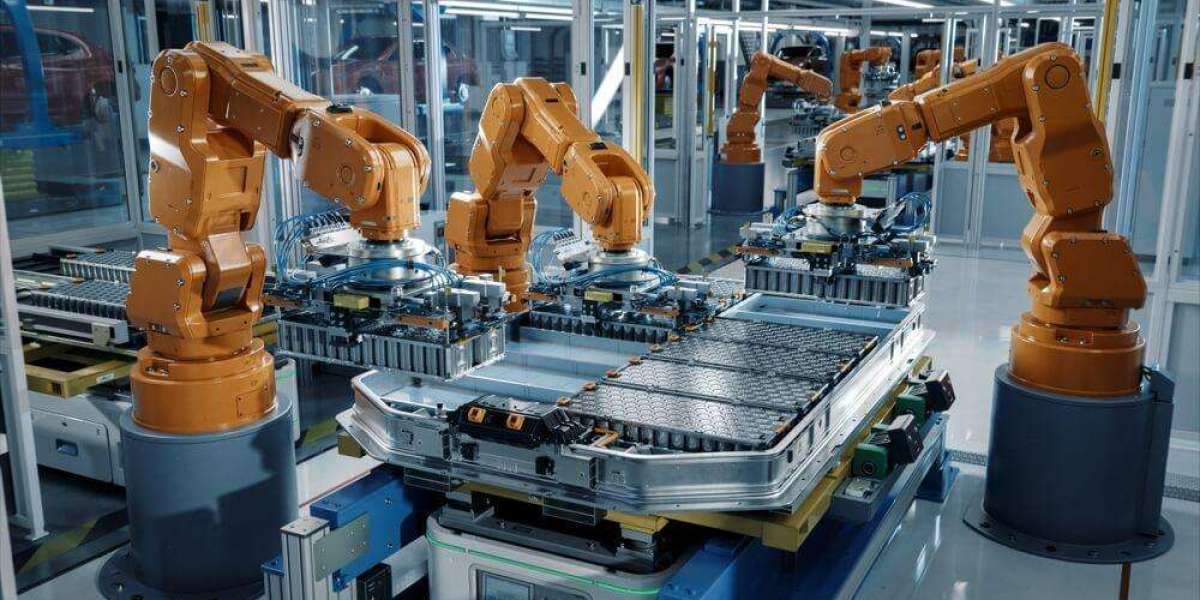

The backbone of this transformation is the integration of smart technologies — IoT, artificial intelligence, robotics, and big data analytics — which are reshaping traditional production lines into intelligent, interconnected networks. These advanced technologies are enabling industries to become more agile, responsive, and resilient. Moreover, the shift towards sustainable practices, including energy-efficient manufacturing, is further reinforcing the adoption of automation.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the "India Industrial Automation Market"@https://www.techsciresearch.com/report/india-industrial-automation-market/15147.html

Emerging Trends in India’s Industrial Automation Landscape

Rise of Industry 4.0 and Smart Manufacturing

Industry 4.0 has emerged as the cornerstone of India’s industrial evolution. The fusion of digital technologies with manufacturing processes has led to the rise of smart factories — environments where machines, systems, and humans collaborate seamlessly. Automation is no longer restricted to basic functions; it has evolved into an ecosystem that thrives on predictive analytics, self-learning systems, and autonomous operations.

Real-time data monitoring and decision-making are revolutionizing production planning and maintenance operations. Predictive maintenance, enabled through IoT and AI, helps businesses avoid costly downtimes by foreseeing equipment failures. This trend is particularly prevalent in high-value sectors such as automotive, aerospace, and electronics, where precision and efficiency are paramount.

Human-Robot Collaboration (Cobots)

Collaborative robots, or cobots, are transforming assembly lines by working alongside human operators. These robots are designed to assist rather than replace workers, significantly increasing productivity while ensuring safety. Cobots are increasingly being deployed in mid-sized enterprises due to their flexibility and cost-effectiveness. Their ability to adapt to various tasks and quick deployment is making them popular in India’s fast-growing SME sector.

Cloud-Based Automation and Edge Computing

As manufacturing processes generate enormous amounts of data, cloud computing is becoming integral to data storage and processing. Cloud-based automation platforms provide centralized control, seamless scalability, and easier software updates. Complementing this, edge computing enables faster data processing closer to the source, enhancing real-time analytics and decision-making — essential for applications requiring minimal latency.

Cybersecurity and Industrial Automation

With increased connectivity comes increased vulnerability. Cybersecurity is gaining prominence in the automation landscape. Industrial control systems and smart devices must be protected from data breaches and malicious attacks. Companies are now integrating cybersecurity frameworks directly into automation architectures to safeguard critical infrastructure.

Green Automation and Sustainability

Sustainability is influencing design choices and operational goals. Smart automation systems equipped with energy monitoring capabilities are helping companies reduce their carbon footprint and comply with environmental regulations. Sustainable manufacturing, aided by automation, supports optimized resource consumption, waste reduction, and energy conservation.

Key Market Drivers

Government Initiatives Fueling Modernization

India’s ambitious "Make in India" and "Digital India" programs are creating a favorable policy environment for industrial modernization. These initiatives aim to make India a global manufacturing hub by incentivizing technological upgrades and automation investments. Tax incentives, ease of doing business reforms, and PLI (Production Linked Incentive) schemes have catalyzed the adoption of smart manufacturing practices.

Increasing Demand for Operational Efficiency

Industries are under growing pressure to deliver high-quality products at reduced costs. Automation offers solutions by minimizing human error, reducing production times, and optimizing resource utilization. Companies are prioritizing automation to maintain competitiveness in global markets.

Workforce Challenges and Skill Gaps

India's large workforce presents both a challenge and an opportunity. While labor is relatively inexpensive, rising skill gaps and the need for precision are pushing companies towards automation. Automated systems can perform repetitive and hazardous tasks, allowing the workforce to focus on more complex and strategic roles.

Competitive Landscape

Key market players in the India Industrial Automation Market are: -

- Siemens AG

- ABB Ltd.

- Rockwell Automation, Inc.

- Schneider Electric SE

- Honeywell International Inc.

- Mitsubishi Electric Corporation

- FANUC Corporation

- Hitachi, Ltd.

Customers can also request for 10% free customization on this report.

Future Outlook

The future of India’s industrial automation landscape looks promising, with technology continuing to disrupt traditional models. As businesses recognize the strategic value of automation beyond operational efficiency — including agility, sustainability, and innovation — the market will witness accelerated growth.

Key future developments include:

Rise of 5G-powered automation: Low latency and high-speed connectivity will unlock real-time communication between devices, critical for autonomous operations.

Growth of software-defined manufacturing: Virtual models and digital twins will enable simulation and optimization of production processes.

Expansion of SMEs into automation: Cost-effective solutions tailored for small and mid-sized manufacturers will democratize access to automation.

Focus on cybersecurity: Secure-by-design automation systems will become a standard to counter rising cyber threats.

Integration of blockchain in supply chains: Enhancing traceability and transparency through automated ledgers.

India is on a transformative journey, moving towards becoming a global manufacturing powerhouse. The integration of intelligent automation will play a decisive role in this evolution. As new technologies emerge and adoption becomes mainstream, the India Industrial Automation Market is set to scale new heights, reshaping the future of manufacturing and industrial productivity.

Contact US:

Techsci Research LLC

420 Lexington Avenue, Suite 300,

New York, United States- 10170

Tel: +13322586602

Web: https://www.techsciresearch.com/