Laminated busbars are engineered components used in electrical and electronic systems to efficiently distribute power while minimizing inductance, resistance, and electromagnetic interference. These compact, multi-layered conductors — typically made from layers of copper or aluminum separated by insulating materials — are increasingly adopted in power electronics, renewable energy systems, electric vehicles (EVs), and industrial automation.

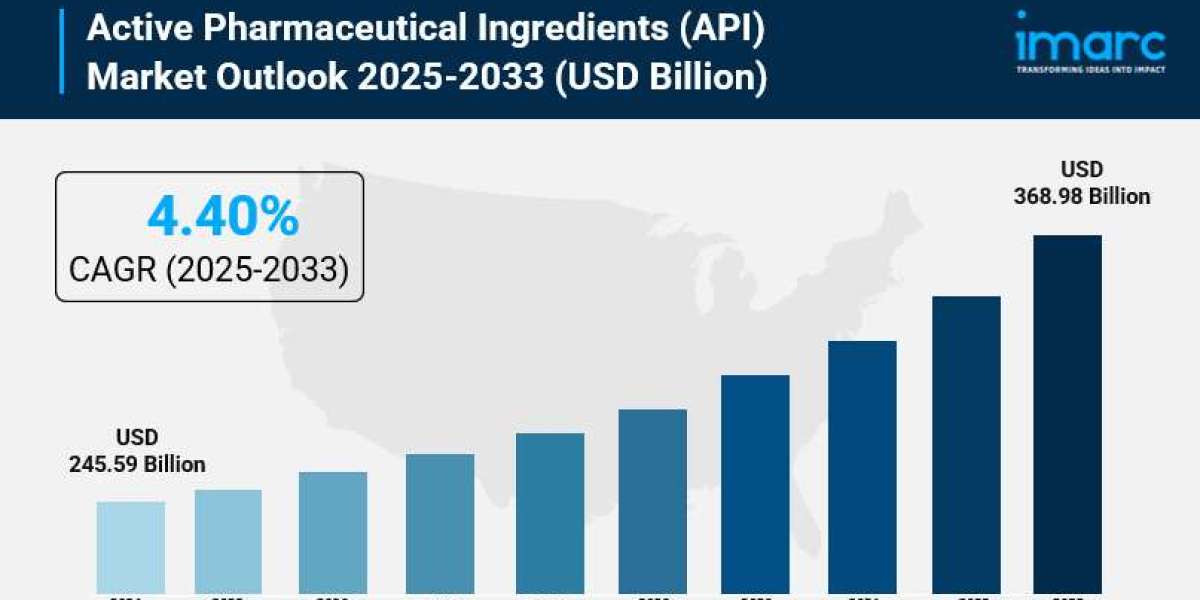

The global laminated busbar market is expanding rapidly due to growing demand for compact, high-performance electrical interconnect solutions. The shift toward electrification, renewable energy integration, and miniaturization of electrical systems is driving industries to adopt laminated busbars over traditional wiring and cabling methods. These busbars ensure better thermal management, higher current-carrying capacity, and reduced system complexity.

Market drivers include the proliferation of EVs, where laminated busbars are used in battery modules, inverters, and power distribution units to manage heat and space constraints. Additionally, renewable energy applications — particularly in solar inverters, wind turbines, and battery energy storage systems — benefit from the low inductance and improved electrical performance that laminated busbars provide. The industrial automation sector also uses these components to ensure reliable power flow in robotics, motor drives, and control systems.

From a technology perspective, recent innovations are focused on advanced materials, improved insulation systems, and automated manufacturing techniques. High-speed production and custom designs tailored to application-specific needs are making laminated busbars more accessible and cost-effective. Integration with smart sensors and condition monitoring systems is emerging to support predictive maintenance in mission-critical applications.

Regionally, Asia-Pacific leads the global market, primarily due to the dominance of China, Japan, and South Korea in electronics manufacturing, EV production, and renewable energy expansion. North America is witnessing strong growth due to investments in energy storage systems and grid modernization, while Europe continues to lead in renewable energy installations and electric mobility initiatives.

In conclusion, laminated busbars are a cornerstone of modern electrical systems, offering space-saving, low-loss, and high-reliability power distribution solutions. As energy systems become more complex and compact, laminated busbars will remain vital in ensuring efficient and safe power delivery across a wide range of industries.