Powering Precision: The Unmatched Reliability of the ZJP Roots Vacuum Pump in Industrial Applications

In today’s fast-paced industrial world, precision and reliability are the cornerstones of successful operations. Whether in electronics, pharmaceuticals, metallurgy, or chemicals, vacuum systems play an essential role in achieving clean, controlled environments. Among the leading technologies in vacuum engineering is the ZJP Roots Vacuum Pump, a powerhouse known for its dry operation, high-speed performance, and operational stability. This article explores what makes the ZJP Roots Vacuum Pump a critical component in industrial vacuum systems, its core design principles, applications, and the benefits it delivers across various sectors.

The Fundamentals of the Roots Vacuum Pump

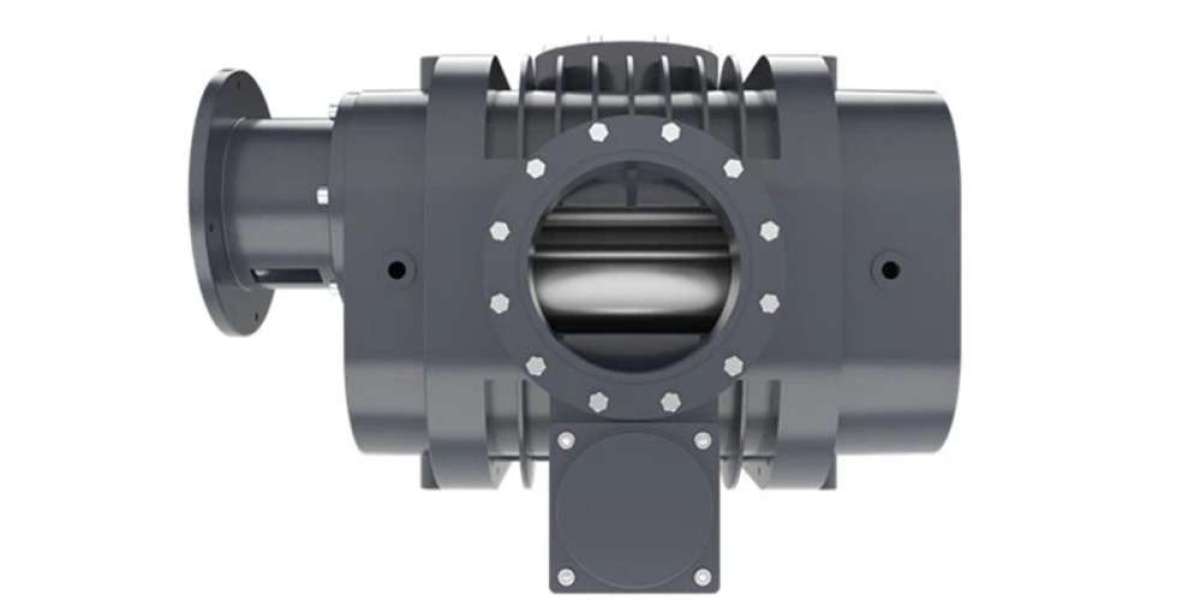

The Roots vacuum pump, often referred to as a Roots blower, is a type of positive displacement pump. It was originally developed in the 19th century by the Roots brothers and has since been widely adapted for industrial use. The fundamental mechanism consists of two rotors—usually in a figure-eight shape—that rotate in opposite directions within a sealed chamber. As they turn, gas is trapped between the rotor lobes and the pump casing and is pushed from the inlet to the exhaust.

Unlike other vacuum pump types, Roots pumps do not compress the gas internally; instead, they rely on the pressure difference between the inlet and outlet, often working in conjunction with backing pumps to achieve deeper vacuum levels. The ZJP series optimizes this principle, offering a high-efficiency, oil-free vacuum solution suitable for modern production demands.

What Is the ZJP Roots Vacuum Pump?

The ZJP Roots Vacuum Pump is a high-speed, dry-running vacuum pump that excels in medium to low vacuum environments. It’s engineered for clean, oil-free operation, making it ideal for industries where contamination control is critical. The ZJP model features a rugged design, high volumetric throughput, and a wide operational pressure range, allowing it to function effectively as a standalone unit or as part of a multi-stage vacuum system.

What sets the ZJP apart is its simplicity, efficiency, and minimal maintenance requirements, combined with high durability under tough operating conditions.

Key Features of the ZJP Roots Vacuum Pump

1. Oil-Free Compression Chamber

One of the most important features of the ZJP pump is that it operates completely oil-free in the vacuum chamber. The bearings and gear mechanism are sealed and lubricated separately, ensuring that the process gas is not exposed to any lubricant. This prevents contamination and enables the pump to be used in cleanroom and sensitive manufacturing environments.

2. High Pumping Speed

ZJP pumps provide rapid evacuation and high throughput. Their high rotational speed and minimal internal clearance mean they can move large volumes of gas quickly, making them ideal for applications that require fast cycle times.

3. Durable and Compact Design

Engineered with precision, ZJP pumps are compact and space-efficient, allowing for easier installation in production environments with limited floor space. Despite their compact form, they are built with robust materials to handle continuous operation and demanding environments.

4. Energy Efficient

Thanks to their dry-running mechanism and efficient rotor geometry, ZJP pumps consume less energy than many traditional vacuum systems, translating to lower operational costs over time.

5. Low Vibration and Noise Levels

ZJP Roots pumps are designed for quiet and smooth operation, which is crucial in laboratory settings or sensitive production lines where vibration and noise can impact results or equipment integrity.

Industrial Applications of the ZJP Roots Vacuum Pump

The versatility of the ZJP pump makes it suitable for a wide range of applications across multiple industries:

• Semiconductor and Electronics Manufacturing

In processes like vacuum drying, degassing, etching, and thin-film deposition, an oil-free and reliable vacuum source is essential. The ZJP pump ensures clean operation without backstreaming oil vapor.

• Chemical and Petrochemical Industry

ZJP pumps are used to handle inert, corrosive, or reactive gases in chemical reactors, distillation columns, and extraction systems. Their dry operation makes them compatible with aggressive chemicals when the correct materials are used.

• Pharmaceutical and Food Production

Cleanliness and contamination control are crucial in drug and food production. ZJP pumps provide a hygienic vacuum solution for applications such as freeze-drying, vacuum filtration, and packaging.

• Metallurgy and Heat Treatment

Vacuum furnaces and metal processing often require sustained vacuum levels at high temperatures. The ZJP pump can handle the thermal stress and long-duty cycles typically required in these operations.

• Research and Development Laboratories

From surface analysis instruments to space simulation chambers, ZJP pumps deliver stable vacuum conditions vital for accurate experimental results.

Benefits of Using the ZJP Roots Vacuum Pump

The ZJP Roots Vacuum Pump brings a wide range of advantages to the table:

- Contamination-Free Operation – No oil contact with the process gas ensures pure vacuum conditions.

- Lower Maintenance Requirements – With fewer parts in contact and no oil change needed in the compression chamber, maintenance is simple and infrequent.

- Quick Startup and Shutdown – The ZJP pump reaches full operational speed quickly, enhancing productivity.

- Flexibility in System Integration – Whether used with backing pumps or as part of a multi-stage vacuum system, the ZJP integrates seamlessly into existing configurations.

- Environmentally Friendly – The dry operation eliminates oil disposal concerns and aligns with eco-friendly industrial practices.

Maintenance and Operational Tips

To maximize the lifespan and efficiency of a ZJP Roots pump, basic maintenance routines should be observed:

- Check Gear Oil Levels in the sealed gearbox and top up or replace as needed.

- Inspect Bearings and Seals periodically for wear, particularly in high-duty cycles.

- Ensure Clean Inlet Gas by using proper filters if the pump is exposed to dust or particulates.

- Monitor Rotor Alignment to prevent excessive vibration or clearance issues over time.

With these minimal upkeep measures, a ZJP Roots pump can serve reliably for many years.

The Future of ZJP Roots Vacuum Technology

As industries demand higher levels of cleanliness, efficiency, and automation, the ZJP Roots Vacuum Pump is evolving to meet modern expectations. Newer models are being designed with smart controls, IoT integration, and predictive maintenance capabilities, allowing for remote diagnostics and energy optimization.

Future enhancements may also include advanced coatings, hybrid materials, and adaptive speed controls, ensuring even greater durability and efficiency for emerging technologies and sustainable manufacturing practices.

Conclusion

The ZJP Roots Vacuum Pump represents the perfect combination of simplicity, strength, and sophistication in vacuum technology. Its oil-free, high-performance operation and low maintenance design make it indispensable for a wide range of industries seeking clean and efficient vacuum solutions. Whether you’re managing a high-tech semiconductor plant or a cutting-edge research lab, the ZJP pump delivers the power, reliability, and cleanliness required to keep operations running at their best. Click here to view more details https://www.bokevac.com/