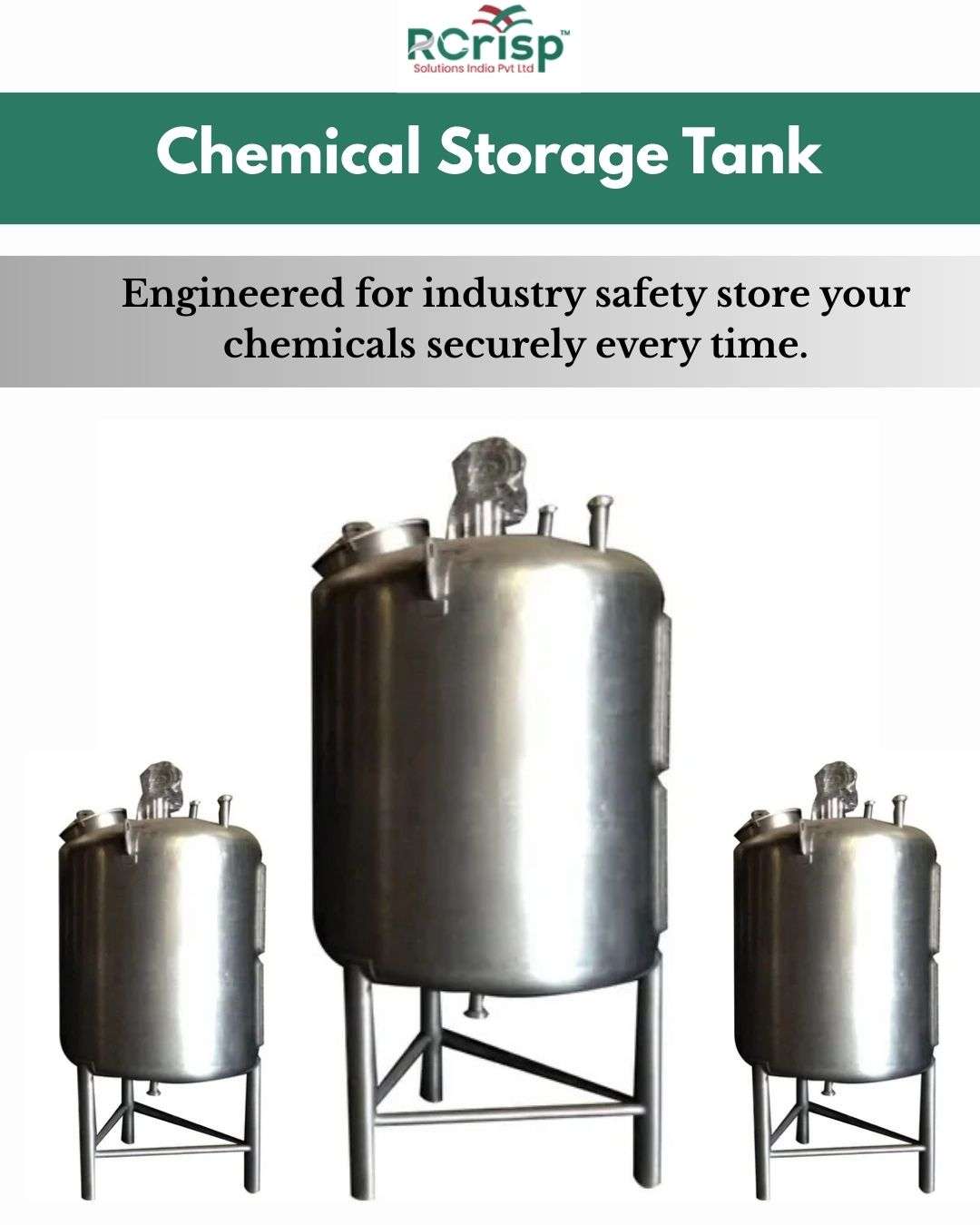

RCRISP SOLUTIONS appreciates the importance of chemical storage tanks in the industry all over the world. They are more than just tanks. They serve as storage units for hazardous and non-flammable liquids and provide a safe mechanism for the storage and handling of such liquids, protecting workers and the environment. Our company, with over twenty years of experience, has seen how safety, compliance, and efficiency are enhanced in all industries when investing in the correct storage solution. Large storage silos with the appropriate chemical storage tank are important in preventing leaks, contamination, and expensive accidents.

Usage of Chemical Storage Tanks in some Industries.

Industries like manufacturing, chemical processing, pharmaceuticals, and agriculture heavily depend on chemical storage tank to safely bulk store their chemicals. The tanks go beyond storage and serve other important functions like

Safety: Enclosed tanks reduce the risk of leaks, spills, and exposure of harmful chemicals to the workers and the environment.

Safety: with the use of tanks, compliance with safety regulations is a nonissue. These tanks are designed to meet OSHA, EPA and other local regulations, resulting in the avoidance of legal liabilities and public environmental irresponsibility.

Maximizing Space: Your chemical storage silo and tanks will consolidate chemicals into one location and free up valuable floor space for other, more productive operations.

Improvement in Operations: Your bulk storage means not only fewer containers to manage but also simpler overall inventory and labor cost efficiencies.

Protecting People and the Environment: The most important consideration of chemical storage and chemical storage tanks is the people and the environment. Chemical storage tanks help to

Prevent Leakage and Spills: Double-walled tanks and corrosion-resistant materials will eliminate the escape of any and all harmful chemicals.

Reduce Handling: The use of larger tanks means a reduced number of transfers of the chemicals, therefore reducing the chances of a spill.

Monitor Contents: Sensors and level indicators tracking the volume of chemicals in the tank assist in preventing overfilling or even a shortage.

Containment of Dangerous Chemicals: Chemical storage silos designed for certain chemicals will provide the proper stable surroundings to eliminate the chances of an environmentally hazardous reaction.

Investing in Quality Tanks: As a result of experience and reliability, chemical storage tank manufacturers have learned that there is a positive return on investment attributable to the use of quality storage tanks.

Material and Construction: Does the most should provide the most. Selecting the right chemical storage tank should consider the chemical nature and the intended storage conditions. Tanks come in various materials.

Polyethylene and Fiberglass: Polyethylene is ideal for the storage of many acids and corrosive chemicals due to its resistance properties. Fiberglass Reinforced Plastic is also lightweight and offers more strength for a diverse array of chemical storage.

Stainless Steel: Ideal for high-endurance applications involving extremely reactive chemicals or extremely high temperatures.

At RCRISP SOLUTIONS, our chemical storage tank is constructed with premium materials built for long-term performance with minimal maintenance.

Maximizing Space with Vertical Storage Silos

Massive storage: Perfect for keeping large amounts of chemicals, so you don’t have to refill over and over again. Storage Silos: A Unique Variant of Chemical Storage Tanks Storage silos are large vertical structures designed for the storage of chemicals, especially powders and granules, although they may also hold liquids. They provide:

Effective space utilization: The vertical design allows for the economical use of ground space.

Shielding from moisture: Silos provide an airtight seal, preventing moisture and other impurities from contaminating the stored materials.

In large-scale industrial facilities, the use of storage silos and chemical storage tanks together improves the overall available storage solutions.

What Ways Do Chemical Storage Tanks Improve Efficiency and Reduce Expenses?

From our experience, chemical storage tanks can provide multiple cost-saving advantages:

- Reduced operational expense: Having a single storage unit for multiple consolidated chemicals reduces the maintenance and supervision labor for single-use containers.

- Longevity of Chemicals: You reduce deterioration and contamination through proper storage.

- Less Downtime: Proper monitoring of available chemicals keeps track of chemicals and avoids stopping production processes.

- Less Cost Related to Spills: The tanks are designed to reduce the legal penalties and expenses after a spill.

The choice of RCRISP SOLUTIONS chemical storage tanks allows companies to achieve a high return on investment while ensuring the safety of the employees.

Compliance and Environmental Responsibility

Chemicals are everywhere, and every industry has an obligation to comply with safety and environmental regulations. Chemical storage tanks made by vetted manufacturers like RCRISP SOLUTIONS are fully compliant and provide:

Legal compliance: No legal fines or shutdowns.

Lowered environmental risks: No toxic leakage and protection from chemical exposure to local life.

Corporate citizenship: Commitment and responsibility to community health and sustainable practices.

Installation and Maintenance

Today’s chemical storage tanks are built for ease of installation and maintenance. Numerous tanks are prefabricated and can be set up in minutes. Scheduled repairs are less frequent due to specialized tank linings and coatings that slow corrosion and extend tank life.

Inventory Control and Monitoring

- Fully equipped chemical storage tanks provide industries with the ability to:

- Monitor current chemical levels in real time.

- Order at precise intervals.

- Maintain optimal stock levels.

- Streamline purchasing.

- Cost-effective control is critical to the industry at this level.

- Choosing the Right Chemical Storage Tank Manufacturer

Choosing chemical storage tank manufacturers to ensure the reliability of the product is the most critical aspect. RCRISP SOLUTIONS has received sector-specific service for over 20 years and supplies durable tanks to all industries. Our experience will guarantee that our clients will have bespoke storage systems with complete tailored after-sales services.

Conclusion

An industrial chemical storage tank is essential for any industrial activity due to its safety features, effective designs, and regulatory compliance. RCRISP SOLUTIONS manufactures high-quality chemical storage tank and storage silos that protect employees, cut costs, and improve overall efficiency. It is choosing a reputable name with proven experience. Get your chemical storing units now.

For safe and budget-friendly tank storage for your chemicals for industrial operations, contact RCRISP SOLUTIONS and enhance your industrial operations today!

SOURCE URL:

https://rcrispsolutions.blogspot.com/2025/11/how-do-chemical-storage-tanks-improve.html