Automated Homogenizers Market Overview

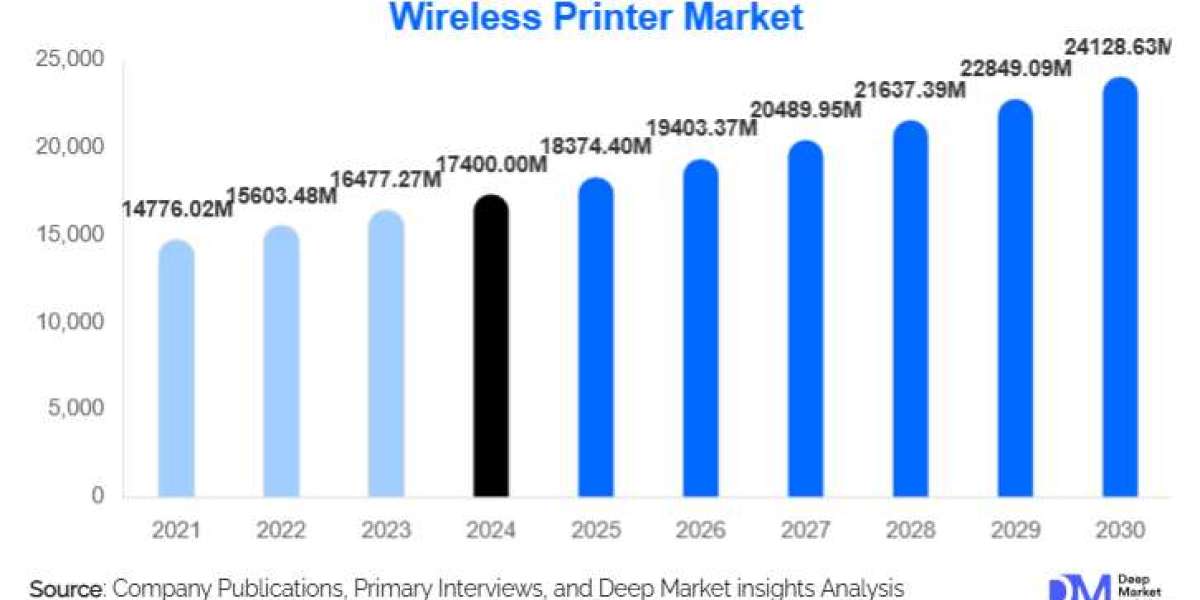

The global Automated Homogenizers market was valued at US$ million in 2024 and is anticipated to reach US$ million by 2031, witnessing a CAGR of %during the forecast period 2025-2031.

The automated homogenizers market is growing steadily as industries seek higher product consistency, better stability, and faster production with minimal manual intervention. An automated homogenizer is a processing system designed to reduce particle size and distribute solids, oils, or droplets uniformly within a liquid. By using automated controls, sensors, and programmable settings, these machines deliver repeatable results across batches while improving hygiene and reducing operator workload. Automated homogenizers are widely used in dairy and beverages, pharmaceuticals, biotechnology, cosmetics, chemicals, and food ingredients, making them an essential technology in modern manufacturing lines.

Read Full Research Report: https://www.qyresearch.in/report-details/1598423/Global-Automated-Homogenizers-Market-Insights

Key Drivers Fueling Market Growth

One of the strongest drivers in the automated homogenizers market is the rising demand for consistent quality in high-volume production. In sectors such as dairy, sauces, nutraceuticals, and injectable drugs, even small variations in particle size distribution can affect shelf life, taste, texture, appearance, and efficacy. Automation helps manufacturers control critical parameters such as pressure, temperature, flow rate, and cycle time with precision. Another key factor is the growing focus on regulatory compliance and traceability. Automated systems can log process conditions, generate digital records, and support validation protocols, which is particularly valuable for pharmaceutical and biotech users.

How Automated Homogenizers Improve Product Performance

Automated homogenization enhances product stability by preventing separation, creaming, or sedimentation. In beverages and dairy, homogenization improves mouthfeel and keeps fat globules evenly dispersed. In pharmaceuticals, it supports uniform suspensions and emulsions for topical, oral, or injectable formulations. In cosmetics, it contributes to smoother creams and lotions with consistent texture and appearance. Automation further strengthens these benefits by ensuring every run follows the same parameters, reducing rework, minimizing product waste, and improving overall equipment effectiveness.

Market Segmentation by Technology and End Use

The automated homogenizers market can be segmented by technology into high-pressure homogenizers, ultrasonic homogenizers, rotor-stator homogenizers, and microfluidizers. High-pressure systems are commonly used in dairy, beverages, and pharmaceutical emulsions due to high throughput and strong particle reduction capability. Ultrasonic systems are preferred for laboratory and small-batch applications where precise dispersion is needed. Rotor-stator designs are often selected for viscous products in cosmetics and food processing. By end use, major segments include food and beverages, pharmaceuticals and biotechnology, cosmetics and personal care, and specialty chemicals. Growth is particularly strong in pharma and biotech as advanced drug delivery systems and biologics require tighter control over formulation stability.

Automation Features and Technology Trends

Modern automated homogenizers are increasingly equipped with smart controls and integrated monitoring. Common features include touchscreen interfaces, recipe management, automated cleaning cycles, pressure and temperature sensors, safety interlocks, and remote diagnostics. Many manufacturers are moving toward Industry 4.0-ready homogenizers that can connect with plant-level systems for real-time monitoring and predictive maintenance. Energy efficiency is another key trend, with improved pump designs and optimized flow paths reducing power consumption while maintaining performance. In hygienic industries, demand is also rising for automated clean-in-place (CIP) and sterilize-in-place (SIP) capabilities to reduce downtime and contamination risks.

Regional Outlook and Demand Patterns

North America and Europe represent mature markets for automated homogenizers, supported by established food processing, pharmaceutical, and cosmetic manufacturing bases. These regions also emphasize regulatory compliance, making automated documentation and validation features highly desirable. Asia-Pacific is expected to show strong growth due to expanding pharmaceutical production, rising packaged food demand, and increasing investments in modern processing plants. Countries with fast-growing biotech ecosystems and contract manufacturing hubs are also adopting automated homogenizers to support quality upgrades and capacity expansion. Emerging markets are showing interest in scalable and modular systems that can be expanded as production grows.

Competitive Landscape and Future Outlook

The automated homogenizers market is competitive, with suppliers focusing on performance reliability, automation depth, hygienic design, and service support. Buyers increasingly prioritize total cost of ownership, which includes energy consumption, maintenance intervals, spare parts availability, and uptime guarantees. Looking forward, the market is expected to benefit from the continued rise of emulsified and suspension-based products, growth in biologics and specialty formulations, and increasing adoption of smart manufacturing practices. As manufacturers push for consistent output, reduced waste, and stronger compliance, automated homogenizers will remain a high-value investment across multiple process industries.

About Us:

QY Research established in 2007, focus on custom research, management consulting, IPO consulting, industry chain research, data base and seminar services. The company owned a large basic data base (such as National Bureau of statistics database, Customs import and export database, Industry Association Database etc), expert’s resources (included energy automotive chemical medical ICT consumer goods etc.

Contact Us:

QY Research, INC.

315 Work Avenue, Raheja Woods,

Survey No. 222/1, Plot No. 25, 6th Floor,

Kayani Nagar, Yervada, Pune 411006, Maharashtra

Tel: +91-8669986909

Emails - [email protected]