Friction Stir Welding Market Set to Reach USD 367.05 Million by 2030, Driven by Automotive & Railway Sectors

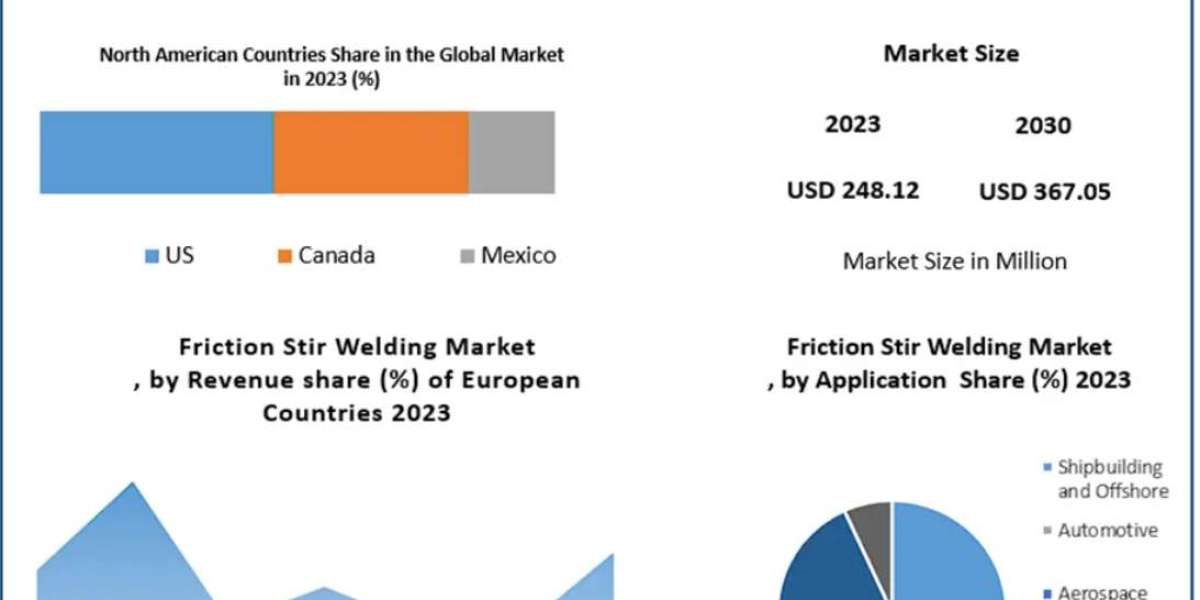

The global Friction Stir Welding (FSW) Market was valued at USD 248.12 million in 2023 and is expected to expand at a CAGR of 5.75% during the forecast period (2024–2030), reaching a market size of USD 367.05 million by 2030, according to recent industry analysis.

For detailed insights, customization, or to request a sample report:https://www.maximizemarketresearch.com/request-sample/10856/

Market Overview

Friction Stir Welding is a solid-state joining process that utilizes a rotating non-consumable tool to join materials without melting them. This unique method eliminates the need for filler materials, shielding gases, or flux, making it a cost-effective and eco-friendly alternative to traditional welding techniques. Known for its ability to produce high-strength, defect-free welds, FSW is rapidly gaining popularity across industries such as automotive, aerospace, railway, shipbuilding, and defense.

Key Market Drivers

1. Rising Demand in Automotive and Railway Industries

The automotive sector's need for lightweight and durable vehicles, driven by electric vehicle (EV) adoption and fuel efficiency goals, is significantly contributing to FSW adoption. Similarly, in the railway sector, demand for cost-effective and high-strength welding for new line construction and track maintenance is boosting the market.

2. Technological Advancements

Leading manufacturers are continually investing in R&D and product innovation. Enhanced FSW machines now feature automated control, adaptive welding capabilities, and real-time monitoring systems, improving weld consistency and cycle time.

3. Cost Efficiency and Eco-Friendly Process

The solid-state nature of FSW reduces energy consumption and the need for consumables, offering manufacturers substantial cost savings. The minimal environmental footprint of this process makes it an attractive option for sustainable industrial manufacturing.

Market Challenges

Despite robust growth, the FSW market faces limitations due to:

Shortage of skilled professionals with FSW-specific training.

Technical complexities during equipment installation and operation.

High initial investment costs, especially for advanced automated systems.

These factors may temporarily hinder the adoption of FSW, particularly among small and medium-scale enterprises.

Segmentation Analysis

By Equipment Type

Fixed Friction Stir Welding machines dominated the market in 2023 with a 52.3% revenue share. Their precision, stability, and adaptability for high-volume production make them ideal for sectors like automotive and aerospace.

Other categories include Adjustable and Self-reacting FSW machines, which are gaining traction for specialized applications.

By Application

Railway sector held the largest market share in 2023 and is projected to grow at a CAGR of 6.02% through 2030.

The automotive segment is expected to experience the fastest growth, driven by increasing EV adoption and structural optimization efforts.

By Material

FSW is applied to materials such as:

Aluminum alloys

Magnesium

Titanium

Copper

Steel alloys

These materials are commonly used in aerospace, defense, and automotive applications where strong, lightweight joints are required.

Request a Free Sample Report or Speak to Our Analysts Today:https://www.maximizemarketresearch.com/request-sample/10856/

Regional Insights

Asia Pacific: Market Leader

The Asia Pacific region, led by China, India, and Japan, held the largest market share in 2023 and is expected to maintain its dominance through 2030.

China continues to lead in automotive production, projected to reach 35 million vehicles annually by 2025.

India’s defense sector saw production surge past USD 12.6 million in 2023, driving further adoption of FSW for military-grade applications.

The region’s booming railway and aerospace sectors are also embracing FSW for its superior mechanical joint strength and reliability.

North America and Europe

North America benefits from robust defense and aerospace investments, particularly in the U.S.

Europe, with technological advancements and automotive innovation hubs in Germany, France, and Italy, contributes significantly to global FSW demand.

Competitive Landscape

The global friction stir welding market is highly competitive, with key players investing in innovation and expansion strategies:

Hitachi High-Technologies Corp. introduced new FSW machines in August 2023, optimized for the automotive and aerospace industries, boasting high productivity and real-time monitoring capabilities.

ESAB, a major welding technology company, launched the Rebel™ FSW device in September 2023, known for its adaptive control and automatic parameter optimization, enhancing usability across various material types.

Key Players in the Market

Hitachi High-Technologies Corp. – Japan

The ESAB Group, Inc. (Colfax Corporation) – USA

KUKA Systems GmbH (Midea Group) – Germany/China

Yamazaki Mazak Corp. – Japan

Concurrent Technologies Corp. – USA

FOOKE GmbH – Germany

Norsk Hydro ASA – Norway

Beijing FSW Technology Co., Ltd. – China

Eta Technology Pvt. Ltd. – India

MegaStir – USA

Grenzebach Maschinenbau GmbH – Germany

Manufacturing Technology, Inc. (MTI) – USA

PaR Systems LLC – USA

These companies are focusing on partnerships, mergers & acquisitions, and new product development to strengthen their market positions and global reach.

Outlook & Opportunities

The global friction stir welding market is positioned for steady and sustainable growth, supported by increasing applications in electric vehicles, defense manufacturing, and infrastructure development. The emergence of automated and AI-integrated FSW solutions further enhances the market potential.

Despite the challenges related to workforce skills and equipment costs, the long-term outlook remains positive due to rising demand from emerging economies, favorable government initiatives, and the increasing need for reliable and efficient joining techniques.

Conclusion

The Friction Stir Welding Market is on a dynamic growth path, with innovation and application diversity at its core. As industries prioritize durability, efficiency, and sustainability, FSW continues to prove its value across sectors. From Asia’s manufacturing boom to North America’s aerospace innovations, friction stir welding is emerging as a critical enabler of next-gen industrial manufacturing.