Introduction

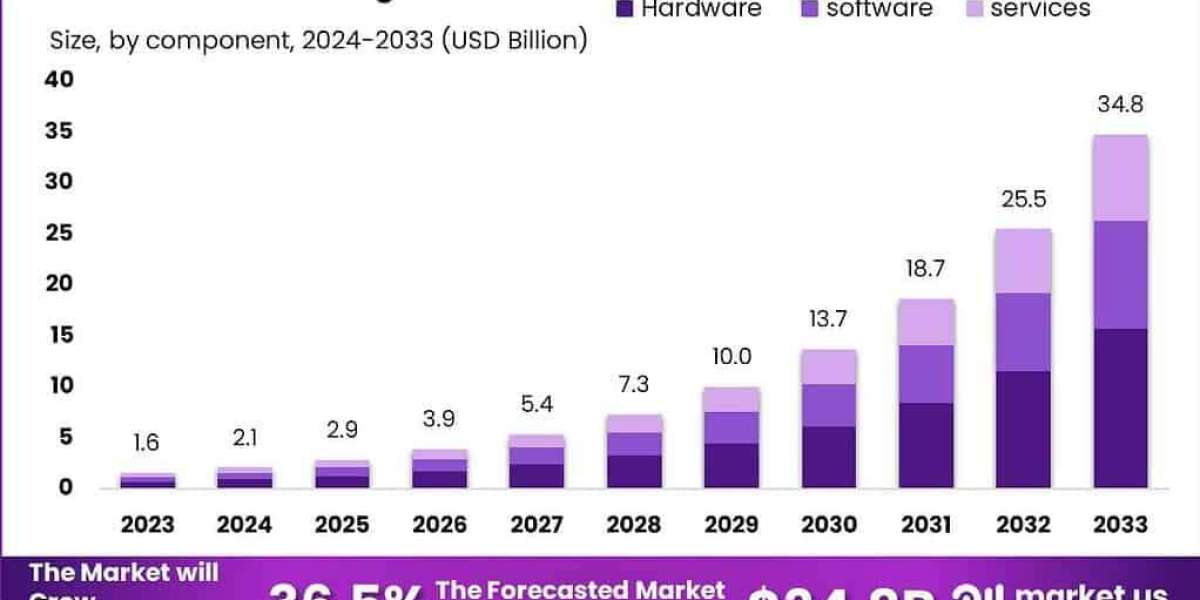

The Global AI in 3D Printing Market, valued at USD 1.6 billion in 2023, is projected to reach USD 34.8 billion by 2033, growing at a CAGR of 36.5%, driven by the demand for precision, efficiency, and customization in additive manufacturing. AI technologies, including machine learning, computer vision, and deep learning, optimize design, production, and quality control. North America leads with a 38% share, fueled by advanced manufacturing infrastructure, while Asia-Pacific grows rapidly due to industrial adoption in China and Japan. This market reflects the shift toward intelligent, automated 3D printing solutions across industries.

Key Takeaways

Market Growth: USD 1.6 billion in 2023 to USD 34.8 billion by 2033, at a 36.5% CAGR.

Growth Drivers: Demand for precision manufacturing and automation.

Leading Segments: Software (48% share), quality control (35%), machine learning (42%).

Challenges: High costs and technical complexity.

Outlook: North America dominates; Asia-Pacific grows fastest at 40% CAGR.

Component Analysis

The market is segmented into hardware, software, and services, with software leading at a 48% share in 2023 due to AI-driven design optimization and process automation. Hardware, including AI-integrated printers and sensors, supports real-time monitoring. Services, growing rapidly, provide integration, training, and maintenance, ensuring seamless adoption in manufacturing workflows.

Application Analysis

Quality control dominates with a 35% share, using AI to detect defects and ensure precision, followed by design optimization for complex geometries. Predictive maintenance reduces downtime by 25%, while process automation enhances production efficiency. AI-driven material selection grows rapidly, driven by demand for customized 3D-printed components.

Technology Analysis

Machine learning leads with a 42% share, optimizing design and predicting failures, followed by computer vision for real-time defect detection. Deep learning, a fast-growing subset, enhances material analysis, reducing waste by 20%. NLP improves user interfaces for design software, streamlining workflows and accessibility in 3D printing processes.

End-User Analysis

The automotive sector dominates with a 40% share, leveraging AI for rapid prototyping and lightweight parts. Aerospace follows, using AI for complex components, while healthcare grows at a 38% CAGR, driven by personalized implants. Manufacturing and consumer goods adopt AI for efficient production and customized products.

Market Segmentation

By Component: Hardware, Software, Services

By Application: Quality Control, Design Optimization, Predictive Maintenance, Process Automation, Material Selection

By Technology: Machine Learning, Computer Vision, Deep Learning, NLP

By End-User: Automotive, Aerospace, Healthcare, Manufacturing, Consumer Goods

By Region: North America (38% share), Asia-Pacific (40% CAGR), Europe, Latin America, Middle East & Africa

Restraints

High implementation costs for AI-integrated 3D printing systems limit adoption, particularly for SMEs. Technical complexities, including integration with existing workflows and a shortage of skilled AI professionals, hinder scalability. Data security concerns and regulatory compliance, such as GDPR for healthcare applications, pose challenges, slowing market growth.

SWOT Analysis

Strengths: Enhanced precision and automation; strong North American adoption.

Weaknesses: High costs and technical complexity.

Opportunities: Expansion in Asia-Pacific and personalized manufacturing.

Threats: Data security risks and regulatory challenges. This analysis highlights AI’s transformative potential in 3D printing against implementation barriers.

Trends and Developments

AI-driven quality control reduces defects by 30%, while cloud-based platforms, like GE Additive’s 2024 Arcam EBM update, cut costs byvalo 35%. Siemens’ 2024 AI design toolkit enhances prototyping. Asia-Pacific’s 40% CAGR reflects China’s USD 2 billion 3D printing investment. Autonomous printing and AI-optimized materials gain traction, boosting efficiency.

Key Players Analysis

GE Additive, Siemens, Stratasys, 3D Systems, and HP Inc. lead, driving AI innovation in 3D printing. GE Additive’s AI-driven Arcam systems optimize production, while Siemens’ NX software enhances design. Stratasys’ 2024 AI material selector and HP’s Multi Jet Fusion AI integration, alongside acquisitions, intensify competition.

Conclusion

The AI in 3D Printing Market is set for rapid growth, driven by precision and automation demands. Despite cost and complexity challenges, opportunities in Asia-Pacific and personalized manufacturing ensure a transformative future. Key players’ innovations will redefine 3D printing by 2033.