The appliance industry has always had a thing for heavy lifting. It deals with a lot of different components that are heavy or oddly shaped. Material handling equipment manufacturers have stepped into the spotlight by designing attachments that aren’t just strong but surprisingly smart. Customized handling attachments are shifting the way appliance makers manage production, logistics, and warehouse operations.

- Product Protection Comes First

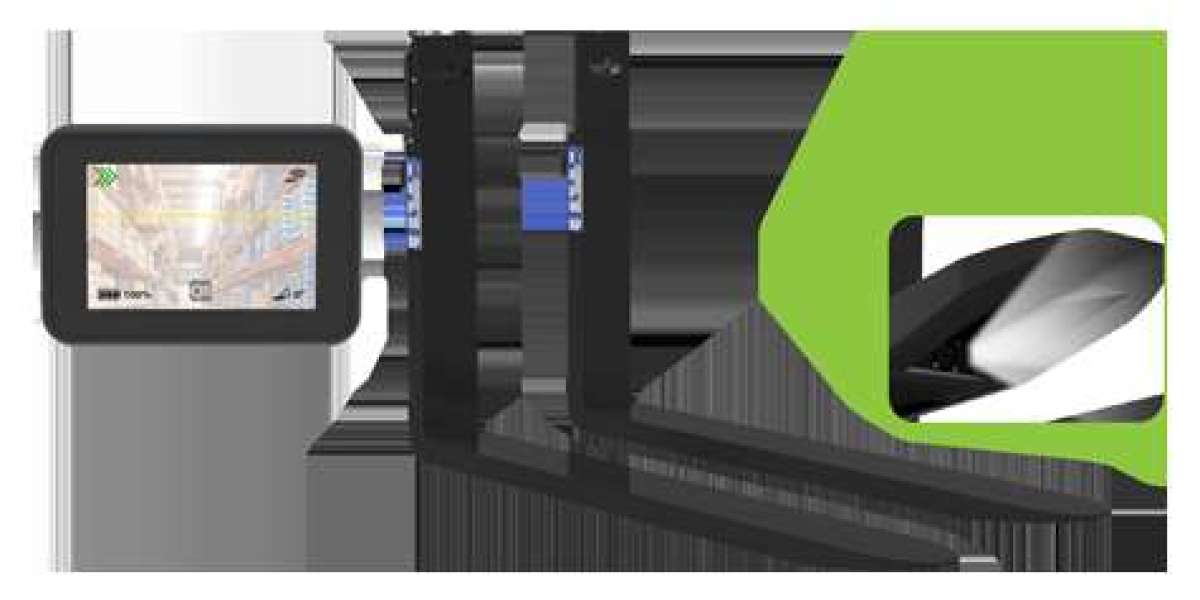

Dishwashers, washers, and ovens all have their own shape, size, and surface finish that doesn’t take kindly to careless treatment. Off-the-shelf clamps and forks don’t always cut it. That’s where customized attachments come in. Designed with specific product profiles in mind, they reduce damage during handling. That means fewer dents, fewer insurance claims, and more happy customers not calling to complain about scratched doors.

- Faster Movement and Fewer Stops

Standard equipment can slow things down when operators are constantly adjusting for awkward fits. With attachments made to match the load, placement and transfer are faster and smoother. When hundreds of units move through an assembly or distribution line daily, those saved seconds add up to serious gains.

- Better Ergonomics for Workers

Customized attachments also reduce the strain on the human element. Ergonomics isn’t just a nice-to-have. It’s a necessity when people are moving bulky items. Proper grip configurations and motion control help workers do their jobs without injuring themselves. Safer conditions also mean fewer injuries and less downtime, which is something any manager can appreciate.

- Smarter Use of Storage Space

Appliances take up space, and stacking them incorrectly isn’t just inefficient; it is risky. Attachments designed to support stable stacking and spacing allows better use of every square foot in a warehouse. That’s especially helpful during peak seasons when inventory runs high and floor space becomes a luxury.

- Ready for the Next Model

While some models stick around for years, appliance designs can shift faster than fashion trends. New dimensions, materials, and surface textures show up, and traditional tools quickly fall behind. A customized attachment can be re-engineered or modified to match the newest specs without replacing entire fleets of machines.

- Savings in the Long Run

From a cost standpoint, the math usually works in favor of customization. It is an upfront investment. But fewer damaged goods, faster workflows, better safety, and improved space usage all point to long-term savings. When the machines are working with the product instead of against it, the whole system benefits.

For appliance manufacturers looking to keep pace with changing demands, it’s worth rethinking how equipment interacts with products on the floor. Material handling equipment manufacturers who specialize in custom attachments aren’t just selling add-ons—they’re offering smarter solutions to everyday industrial headaches.

Conclusion

Customized handling attachments bring order to heavy, awkward, and oddly shaped appliances. These attachments reduce the risk of product damage during transport and storage. They also improve operator efficiency by allowing smoother and more secure handling. To get the best results, forklift parts should be procured from reputable suppliers with proper licensing.