Let’s be honest: there is nothing more frustrating than having a batch of high-end electronics returned from the field because of "mysterious" circuitry failure. You applied the pcba coating thinking your boards were bulletproof, only to find that harsh environments—like the salty air of a coastal wind farm or the sweltering humidity of an industrial plant—have a way of sniffing out the tiniest weakness. It’s a common headache for engineers: you spend weeks on the layout, but the final PCB protective coating peels or cracks when things get real. So, why does this happen, and how can you ensure your pcba coating actually does its job? Let’s break down the pitfalls and the professional fixes that save your reputation (and your budget).

1. The "Invisible" Killers: Why Conformal Coating Fails

Even the best acrylic or polyurethane resins can’t save a board if the coating process control is ignored. When we talk about failures in pcba coating, we aren't usually blaming the material itself, but how it interacts with the substrate and the production environment.

Surface Contamination: The biggest silent killer is what stays on the board before the coating process. Fingerprint oils and flux residues prevent the coating from bonding.

Delamination: This leads to the protective film peeling away like a bad sunburn, leaving your sensitive components exposed to electrochemical migration and short circuits.

Moisture Ingress: If the viscosity of the fluid is off, you get tiny bubbles. Each bubble is a microscopic cave where moisture settles and starts corrosion from the inside out.

Expert Tip: To achieve High-Reliability Coating results, always ensure your boards meet IPC-A-610 Class 3 standards for cleanliness before application.

[Want to prevent delamination? Contact our experts for a free process audit.]

2. Choosing the Right Shield: PCBA Coating Material Comparison

Not all environments are created equal. A pcba coating for a TV remote won't last a day inside an automotive engine bay. To avoid failure, you must match your chemistry to the specific stress it will face.

| Material Type | Pros (LSI Key) | Cons | Best Harsh Environment |

| Acrylic (AR) | Easy to rework; fast drying | Poor solvent resistance | Consumer gadgets |

| Polyurethane (UR) | Chemical resistance | Hard to repair | Industrial & Fuel sensors |

| Silicone (SR) | Thermal stability (200°C) | Poor abrasion resistance | Automotive & Outdoor |

| Parylene (XY) | Vacuum deposition | High cost; slow process | Aerospace & Medical |

Choosing the wrong material is the #1 cause of long-term degradation. Ensure your choice aligns with IPC-CC-830 requirements.

3. Best Practices for PCBA Coating Process Control

To move beyond "luck-based" protection, your electronics manufacturing services (EMS) workflow needs a systematic upgrade in how the pcba coating is applied and verified.

Precision Thickness & Selective Application

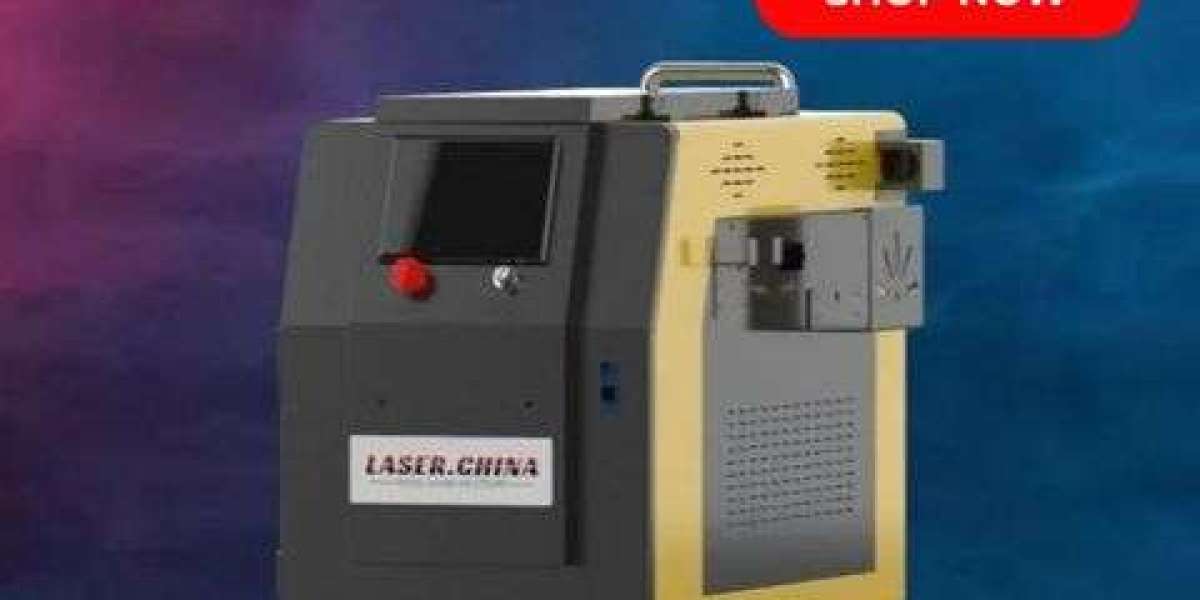

Too thick, and the coating cracks during thermal shock; too thin, and it’s useless. Utilizing automated selective coating machines ensures a consistent micron-level finish while protecting "keep-out zones" like connectors and sensors.

Advanced Validation Techniques

Ionic Contamination Testing: Ensure the board is surgically clean of all ionic residues.

UV Inspection: Use coatings with a UV trace. If it doesn't glow uniformly under a blacklight, your pcba coating will fail in the field.

[Is your current coating process failing? Explore Sanshun Smart’s Automated Solutions today.]

4. Bulletproof Your Electronics with Sanshun Smart

At Sanshun Smart, we’ve seen every pcba coating failure in the book, and we’ve built the precision equipment to stop them. We don't just sell machines; we provide complete, high-reliability coating solutions that guarantee performance in the toughest conditions on Earth. Whether you are struggling with delamination or looking to automate your production line for better coating process control, our engineering team is ready to assist.

Tired of field failures? Check out our Precision PCBA Coating Equipment or contact us for a free technical consultation today.

FAQ: Mastering PCBA Coating Reliability

Q1: What is the ideal thickness for a standard pcba coating?

A: It depends on the material chemistry. For acrylic resins, 30-75 microns is the sweet spot. For silicone, you might go up to 210 microns to handle vibration and extreme heat. Proper coating process control is essential to maintain these tolerances.

Q2: Can I apply pcba coating over "no-clean" flux?

A: While possible, it's risky for harsh environments. The "no-clean" residues can reduce surface energy, leading to poor wetting and eventual peeling. We always recommend a dedicated cleaning cycle for mission-critical boards.

Q3: How do I choose between different PCBA coating materials?

A: Focus on your "worst-case" environmental factor. If it's heat, go Silicone. If it's fuel/chemicals, go Polyurethane. For general moisture in consumer goods, Acrylic is often sufficient.

Q4: Is automated pcba coating better than manual spraying?

A: Absolutely. Automated pcba coating eliminates human error, ensures repeatable thickness, and is the only way to consistently meet IPC-Class 3 reliability standards for industrial and medical electronics.