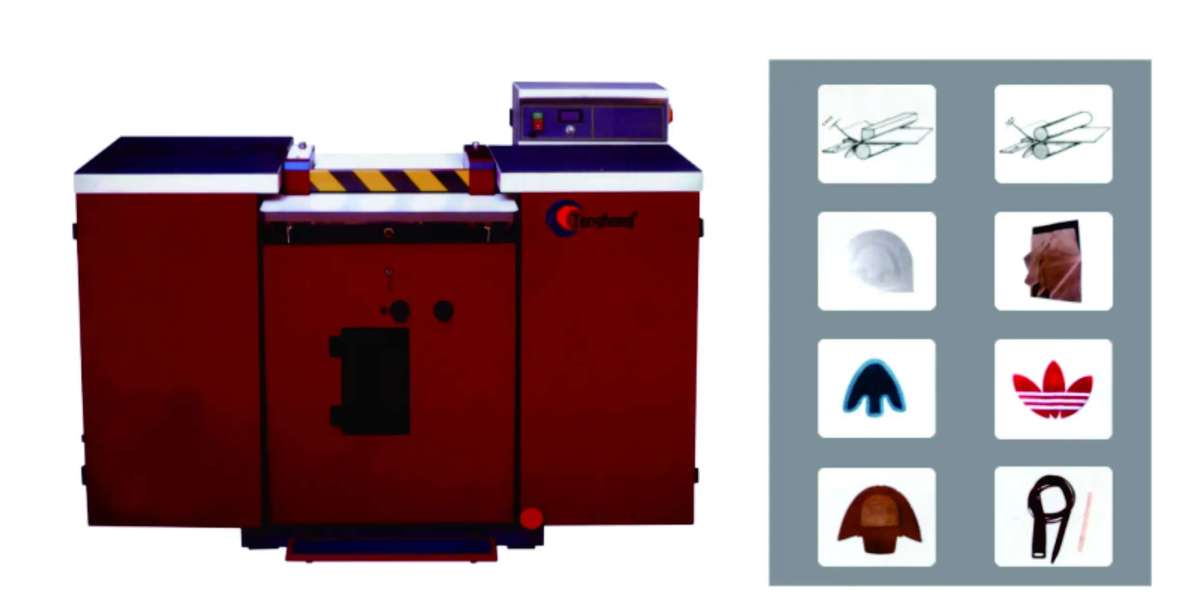

Precision Redefined: Explore the TH-400A Band Knife Splitting Machine by Guangdong Tenghong Machinery

As the demand for high-quality leather products continues to rise, manufacturers worldwide are looking for ways to improve precision, consistency, and efficiency in material processing. The TH-400A Band Knife Splitting Machine from Guangdong Tenghong Machinery Technology Co., Ltd. represents the forefront of leather manufacturing innovation — delivering precision splitting, automated control, and proven reliability to meet the needs of modern production lines.

This state-of-the-art band knife splitting machine is designed for cutting and thinning leather to exact thicknesses, enhancing productivity while maintaining superior surface quality. Featuring a digital control system, automatic positioning, and unsurpassed stability, it has become a must-have tool for footwear, handbags, furniture, and automotive leather goods manufacturers seeking long-term performance and accuracy.

Where Technology Meets Craftsmanship

The TH-400A Band Knife Splitting Machine blends intelligent engineering with practical operation, solving challenges commonly faced during manual leather processing. With its advanced digital thickness display, operators can precisely control material thickness and view changes in real time, ensuring every leather piece meets exact design requirements.

Unlike traditional splitters, the TH-400A uses stepless speed feeding regulation, allowing the user to adjust cutting speed smoothly according to the type of leather — whether it’s hard cowhide, soft sheepskin, or synthetic materials. This control enhances process accuracy and prevents over-thinning or damage to high-quality hides.

Its fully automatic feeding and positioning device eliminates the need for manual tool adjustments, greatly reducing setup time and improving operator convenience. The cutting gap between the knife and pressure plate automatically adjusts itself to achieve optimum precision during every cycle, making it ideal for continuous industrial use where maintenance efficiency and consistency are crucial.

Reliable Hydraulic Design for Uniform Splitting

Another highlight of the TH-400A Band Knife Splitting Machine is its large flywheel structure, engineered to provide stable, vibration-free blade operation. This precision mechanism ensures cutting uniformity across the entire material width, minimizing wastage while enhancing edge symmetry. The integrated electronic phase detection system ensures precise motion synchronization between components, resulting in smoother and cleaner splits.

The machine adopts a 2830/3570mm band knife blade, known for its durability and cost-effectiveness. This long blade design maintains sharpness longer and reduces replacement frequency, directly lowering operational costs. Combined with independent chip vacuum extraction, the system keeps the workspace clean and safe from flying debris or material dust. These thoughtful design elements not only help maintain consistent quality but also emphasize worker safety and machine longevity.

Stability Meets Safety and Intelligence

Safety and stability are at the heart of this leather splitting machine. The TH-400A is equipped with an automatic shutdown system that activates immediately when the leather becomes jammed or misaligned, protecting both operator and machine. The clever incorporation of a mechanical lubrication system ensures all moving components remain well-oiled during operation, extending component lifespan while minimizing downtime.

Beyond its safety measures, Tenghong designed the machine for continuous, large-scale production environments. The constant lubrication, combined with optimal motor performance, enables smooth operation even under demanding workloads. Additionally, the knife sharpening device can be adjusted easily via a single handle, controlling the sharpening cycle automatically to maintain cutting efficiency without manual intervention.

The ergonomically designed working height ensures operator comfort and reduces fatigue, supporting smoother operations throughout long work shifts. By combining human-centered design with digital precision, Guangdong Tenghong has made this model both powerful and user-friendly.

Built for Superior Adaptability in Production

The TH-400A is not just limited to one type of application. Its performance and adjustable systems make it a versatile tool in multiple sectors. The machine processes leather up to 420mm wide and materials with thicknesses less than 8mm, giving it a broad range of compatibility.

In footwear production, it handles shoe uppers, insoles, and lining preparation with perfect thickness balance. In handbag and furniture manufacturing, it refines thick or reinforced hides into leveling materials for luxury goods. Even in automotive upholstery, it delivers uniformity across seats and interior coverings, ensuring smooth texture and durability.

By allowing users to easily adjust the slicing thickness and feed speed, the machine supports mass production while maintaining product uniformity — a vital balance for competitive manufacturers aiming to strengthen brand reputation through flawless craftsmanship.

Energy-Efficient and Cost-Effective Performance

One of the defining strengths of the TH-400A Band Knife Splitting Machine is its energy efficiency. It maximizes output using a motor system that balances power delivery and flexibility. Unlike many industrial machines that consume excess power under strain, the TH-400A maintains optimal performance without overheating or overloading, resulting in longer operational cycles and lower total energy costs.

Manufacturers concerned with sustainability will appreciate this cost-effective design, which reduces energy usage while keeping precision at a premium. Moreover, the vacuum chip device and automatic feed synchronization minimize material waste, further cutting production costs and supporting environmentally conscious business practices.

The reliable internal systems of the TH-400A ensure less downtime and simplified maintenance. Quick blade changeovers, combined with components that are always lubricated, mean fewer delays between production batches — delivering measurable savings over time.

Advancing Industrial Leather Cutting with Guangdong Tenghong Expertise

Behind the success of the TH-400A Band Knife Splitting Machine stands Guangdong Tenghong Machinery Technology Co., Ltd., a leading name in high-performance leather and shoe production machinery. Established in 2000 and located in Houjie, Dongguan, Tenghong blends over twenty years of expertise with international industry innovations.

Recognized globally for its ISO9001:2008 certification and CE-marked machinery, Guangdong Tenghong operates under stringent quality standards and exports its equipment to Southeast Asia, Europe, and beyond. Supported by a team of over 150 engineers and technicians, the company specializes in developing machinery that meets the evolving requirements of global manufacturers — striving for seamless integration between automation, reliability, and affordability.

From pre-sale consultation to machine installation, on-site debugging, operator training, and after-sales maintenance, Tenghong offers full-spectrum service to its clients. This dedication ensures every customer benefits not only from superior equipment but also from a long-term partnership built around shared growth and success.

The company’s philosophy — “shared benefits and ideal achievements” — reflects its commitment to delivering high-quality Chinese engineering that enhances productivity across the global manufacturing marketplace.

The Smart Choice for Future-Ready Manufacturers

Selecting the TH-400A Band Knife Splitting Machine is not just a technological upgrade; it’s an investment in production reliability and precision. By automating key processes like feeding, gap adjustment, and thickness calibration, factories minimize inefficiencies and maximize profitability.

With its extended blade life, durable construction, and ease of operation, this equipment reduces labor dependency while maintaining craftsmanship excellence. The combination of digital control, vacuum-assisted precision, and safety-focused design creates a dynamic system capable of meeting modern industrial demands without sacrificing simplicity or energy efficiency.

For manufacturers seeking a long-term solution that blends automation and artistry, Guangdong Tenghong’s TH-400A offers the perfect balance of performance and value. It’s an all-purpose machine built for scalability, accuracy, and sustainability — three qualities that define success in today’s evolving industrial landscape.