In the demanding sectors of industrial automation and outdoor telecommunications, the performance of pcba electronics is not measured in days, but in years. For many quality managers, the most pressing concern is: "Why do our electronic devices fail prematurely in the field?" When your hardware operates in extreme environments, ensuring the stability of your system requires more than just standard manufacturing—it demands a mastery of failure analysis and proactive reliability engineering.

Understanding the Roots of Failure in PCBA Electronics

Field failures in rugged environments are rarely random. Most issues can be traced back to specific environmental stressors that compromise the integrity of the. Key culprits identified during our diagnostics include:

Electrochemical Migration: High humidity leads to dendritic growth between conductive traces on the board, causing intermittent shorts.

CTE Mismatch: Constant thermal cycling can crack solder joints, a common issue in high-density.

Ionic Contamination: Residual flux or salts accelerate corrosion, leading to the long-term degradation of the assembly.

To combat these, Sanshun Smart integrates rigorous cleaning and ionic testing into its workflow, ensuring that every piece is free of the contaminants that act as precursors to failure.

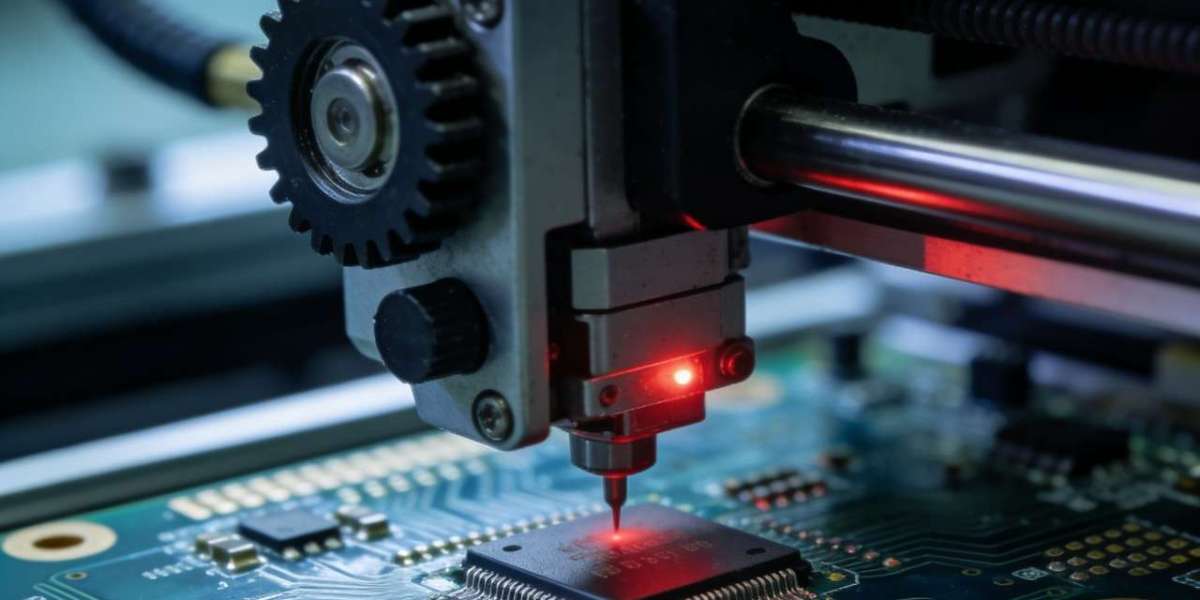

[Image: Microscopic failure analysis in PCBA electronics showing corrosion points]

Strategic Thermal Management for High-Power PCBA Electronics

Heat is the primary enemy of electronic longevity. Effective involves a holistic design approach. At Sanshun Smart, we optimize the heat dissipation through:

High-Thermal Conductivity Substrates: Utilizing metal-core or heavy copper PCBs.

Strategic Component Placement: Isolating heat-sensitive sensors from power modules during the stage.

Advanced TIMs: Implementing high-grade Thermal Interface Materials to bridge components and heat sinks.

Extending the Life of Industrial PCBA Electronics

For mission-critical hardware, is often achieved through automated conformal coating. This specialized thin-film protects against salt spray, moisture, and dust.

As a premier, Sanshun Smart utilizes precision selective coating lines. This ensures that while the vital circuitry of the is hermetically sealed, connectors and test points remain accessible and uncontaminated.

[Image: UV inspection of conformal coating on a high-reliability pcba electronics board]

Conclusion: Reliability as a Core Discipline

Reliability is not an accidental outcome; it is a manufacturing discipline. The longevity of your pcba electronics directly impacts your brand’s reputation and bottom line. Whether you are dealing with automotive stressors or industrial endurance, the technical depth of your provider is your strongest asset.

By leveraging the advanced and protective technologies offered by Sanshun Smart, hardware innovators can move beyond reactive repairs to proactive durability, ensuring their products thrive in the most demanding conditions.