For many hardware companies, the SMT PCBA quotation is one of the most confusing parts of the sourcing process.

Two suppliers quote very different prices for what appears to be the same board—and no one clearly explains why.

This article breaks down SMT PCBA pricing structure in detail, explains where costs actually come from, and shows practical, engineering-backed ways to reduce total cost—not just the unit price.

1. Why SMT PCBA Quotes Often Look “Unclear”

The real concern

Buyers frequently ask:

Why does SMT PCBA pricing vary so much between suppliers?

Which costs are fixed, and which are scalable?

Where does the BOM cost inflate unexpectedly?

The problem is that many quotations only show a final number, without explaining cost drivers.

A professional SMT PCBA quote should always be understood as a combination of manufacturing, materials, testing, and supply chain risk.

2. SMT PCBA Cost Breakdown: What You Are Actually Paying For

A transparent SMT PCBA quotation can be divided into four core components.

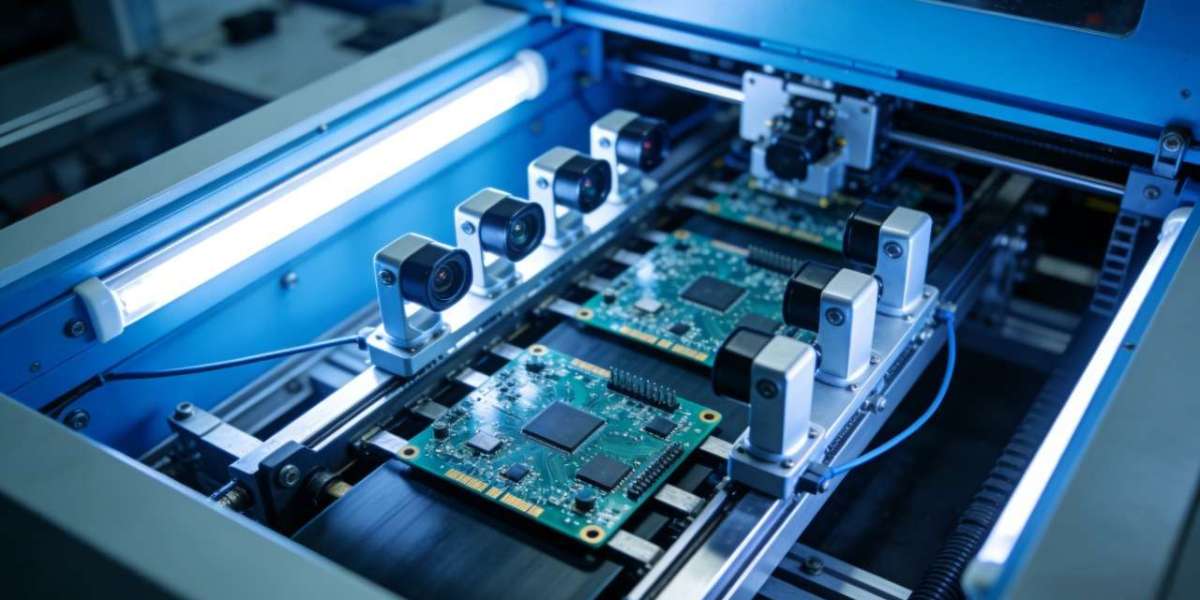

2.1 SMT Assembly Cost

This includes:

Solder paste printing

Pick-and-place operations

Reflow soldering

Basic line setup

Key cost drivers:

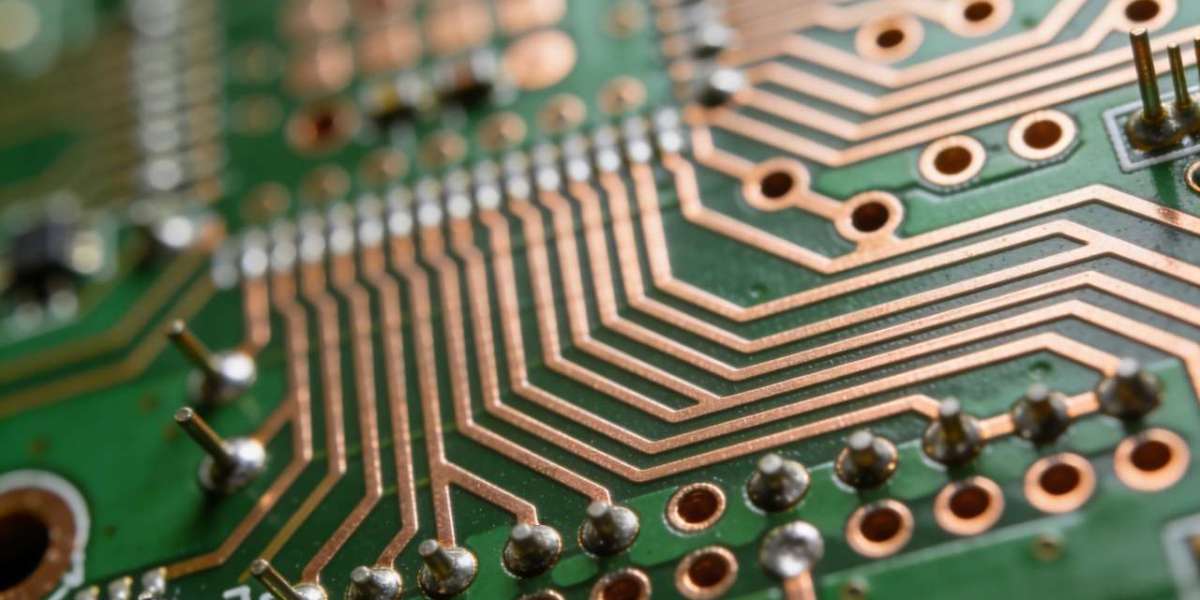

Number of components

Component density and package types (BGA, QFN, fine-pitch parts)

Board size and panelization efficiency

2.2 Testing and Quality Control Cost

Testing is not optional—it directly affects yield and field reliability.

Typical cost elements include:

AOI inspection

Functional testing

X-ray inspection for hidden joints

Low quotes often minimize this section, which may reduce upfront cost but increase long-term failure risk.

2.3 BOM and Component Cost

This is usually the largest portion of the SMT PCBA cost.

BOM cost is influenced by:

Component sourcing channels

Availability and lifecycle status

Packaging and MOQ constraints

One major reason for BOM inflation is poor BOM optimization early in the project.

With a strong engineering team and stable supply chain resources, Sanshun Smart supports PCBA BOM optimization, helping customers:

Identify cost-effective alternatives

Avoid EOL or high-risk components

Reduce unnecessary over-specification

This directly lowers total SMT PCBA cost—not just assembly price.

2.4 Non-Recurring Engineering (NRE) and Setup Costs

Especially relevant for prototypes and low-volume builds.

Includes:

Line setup

Programming

Engineering review

Suppliers with structured NPI processes can amortize these costs efficiently, making small-batch SMT PCBA far more economical.

3. Small-Batch vs Medium/High-Volume SMT PCBA: Cost Differences Explained

Low-Volume / Prototype SMT PCBA

Typical challenges:

Higher setup cost per unit

Lower component price leverage

Cost optimization strategies:

Panelization optimization

Flexible line scheduling

Engineering-led DFM review

Medium & High-Volume SMT PCBA

Cost advantages come from:

Automated placement efficiency

Bulk component procurement

Yield improvement through process tuning

Here, process stability and supply chain strength matter more than headline unit price.

4. How to Reduce Total SMT PCBA Cost (Not Just the Quote)

Practical cost reduction methods that actually work:

BOM optimization before mass production

Early DFM feedback to reduce rework

Choosing the right testing level—not under-testing

Aligning batch size with manufacturing efficiency

The most cost-effective SMT PCBA projects are those where engineering, sourcing, and production decisions are aligned early.

This is why manufacturers with in-house engineering teams—like Sanshun Smart—deliver better long-term cost outcomes than assembly-only suppliers.

5. Why Transparent Quotation Matters More Than the Lowest Price

A low SMT PCBA quote can hide:

Inadequate testing

Unstable sourcing

High failure risk in later stages

A transparent quotation reflects:

Clear cost structure

Predictable production outcome

Lower total cost of ownership

Sanshun Smart emphasizes clear communication and realistic SMT PCBA pricing, allowing customers to make informed decisions rather than chasing artificially low numbers.

6. When to Request an Online SMT PCBA Quote

You should request a detailed SMT PCBA quotation when:

Your BOM is stable or near-stable

You want cost feedback before scaling

You need engineering input for optimization

Online quotation and fast estimation tools help shorten decision cycles and identify cost issues early—before they become expensive problems.

Conclusion: Smart SMT PCBA Pricing Is About Control, Not Guesswork

Understanding SMT PCBA cost structure empowers buyers to:

Compare suppliers fairly

Reduce BOM inflation

Avoid hidden risks

By combining:

Automated SMT PCBA manufacturing

Engineering-driven BOM optimization

Integrated quality control

Transparent pricing logic

Sanshun Smart helps customers reduce total SMT PCBA cost, not just the number on the quote.