The global electronics market is saturated with service providers, making the task of choosing a PCBA partner increasingly complex. For senior engineers and project leads, the stakes go beyond a simple price quote; a poor choice can lead to compromised signal integrity, component lead-time disasters, and high field failure rates.

When evaluating PCBA contract manufacturing partners, you need a framework that moves beyond surface-level marketing. Here are the seven critical factors that define a world-class manufacturing partner.

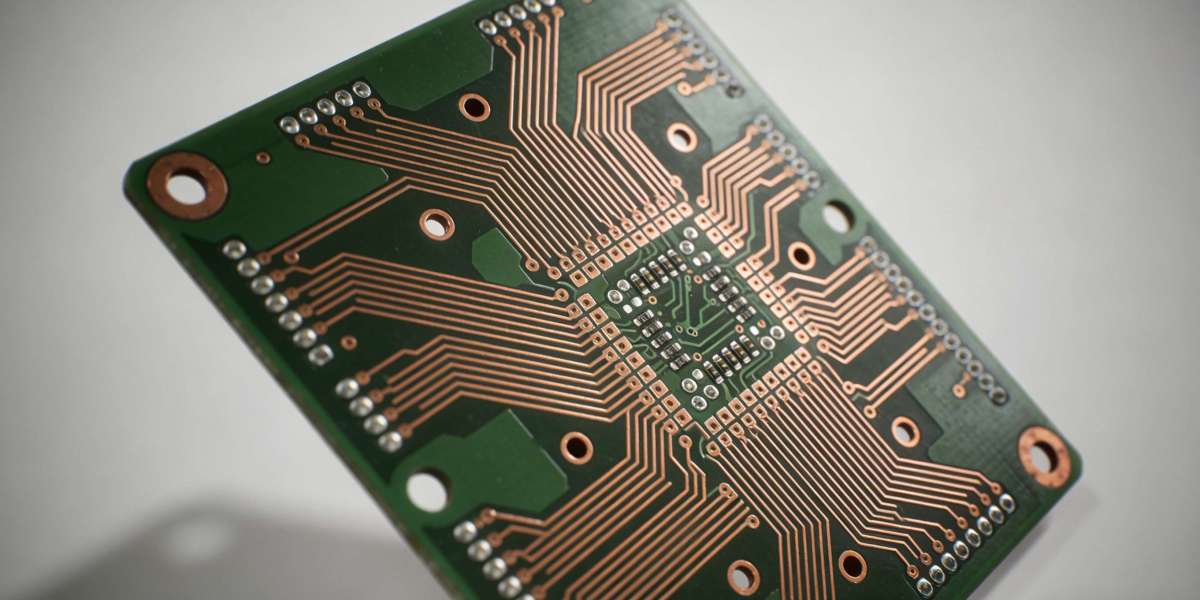

1. Advanced Technical Capability and Hardware Infrastructure

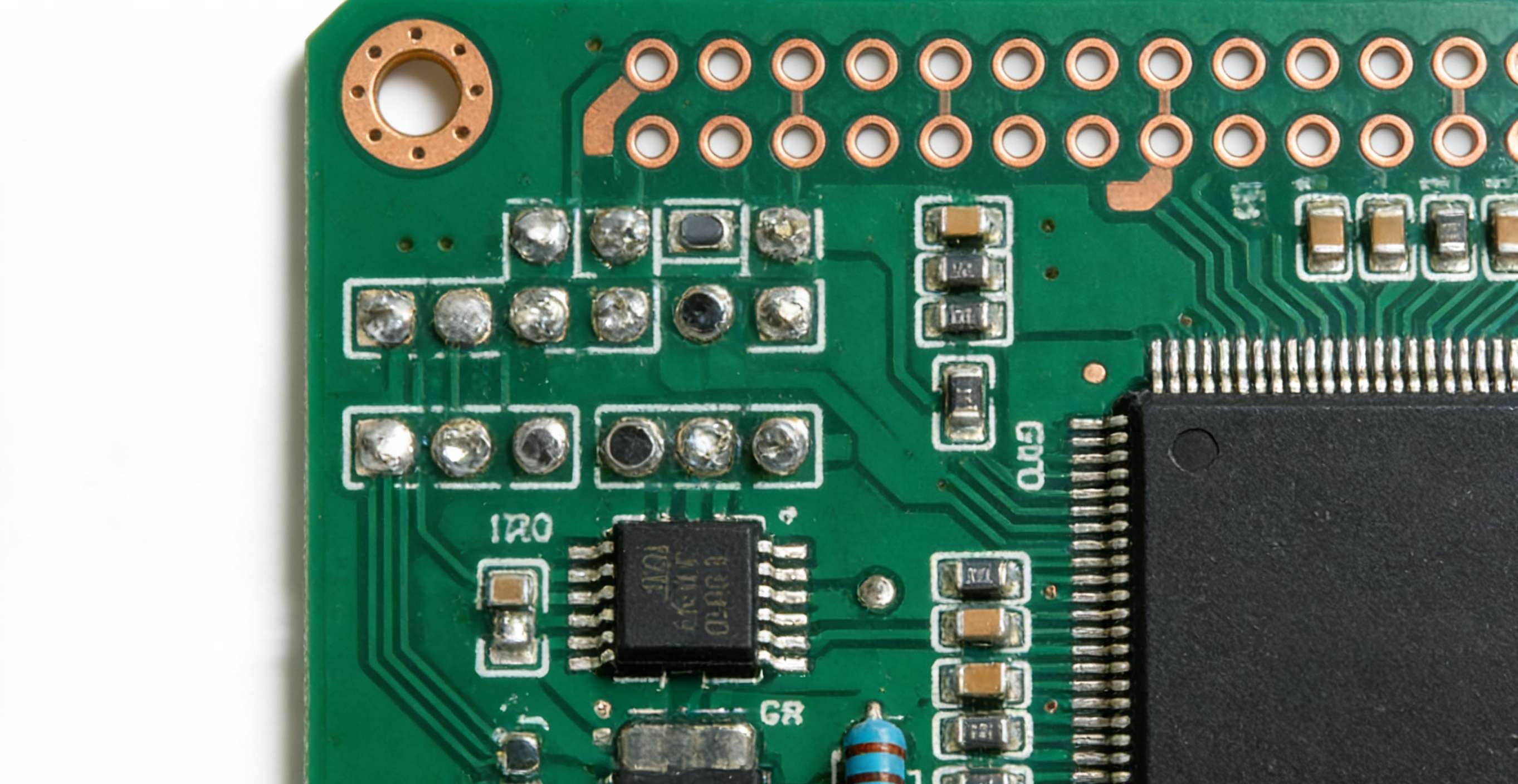

A manufacturer is only as good as the machines on their floor. In the era of miniaturization, you must verify if the provider can handle 0201 components, fine-pitch BGA, and complex double-sided SMT.

The Standard: Look for facilities equipped with 3D AOI, SPI (Solder Paste Inspection), and X-Ray capabilities. High-precision hardware is the only way to ensure quality in high-density designs.

2. Industry-Specific Experience (The 10-Year Benchmark)

Experience in electronics isn't just about time; it's about "manufacturing intelligence." A partner with 10+ years of industry experience has encountered thousands of design flaws and supply chain crises.

Why it matters: Veteran electronic assembly companies can anticipate issues like thermal management problems or component obsolescence before the first board is even printed, effectively de-risking your entire project.

3. Quality Management Systems (QMS) and Certifications

Certifications like ISO9001 and IATF16949 are not just badges; they represent a commitment to standardized processes.

The Insight: For automotive or medical projects, ensure the manufacturer follows a strict traceability protocol where every component can be traced back to its original batch and supplier.

4. DFM (Design for Manufacturing) Integration

The best pcba contract manufacturing partners act as an extension of your engineering team. A robust DFM process identifies potential manufacturing bottlenecks—such as insufficient solder dams or copper-to-edge clearances—early in the NPI (New Product Introduction) phase.

5. Supply Chain Resilience and Component Sourcing

In a volatile semiconductor market, your manufacturer’s sourcing strategy is your lifeline. Evaluate their relationships with authorized distributors and their ability to suggest qualified "drop-in" alternatives for long-lead-time parts without compromising performance.

6. Testing and Inspection Rigor

Manufacturing is only half the battle; verification is the other. Does the manufacturer offer Flying Probe testing, ICT (In-Circuit Testing), and custom Functional Testing (FCT)? A partner that provides a comprehensive test coverage report reduces your "hidden costs" of field returns.

7. Scalability and Flexibility

Your manufacturing partner should be able to grow with you. Can they handle a 10-unit prototype run with the same precision as a 10,000-unit mass production order? Flexibility in batch sizes is crucial for modern, agile hardware development.

Conclusion: Moving Beyond the Quote

Selecting a partner for pcba contract manufacturing is a strategic decision that affects your product's lifecycle and brand reputation. By prioritizing technical infrastructure, decade-long expertise, and rigorous testing, you ensure that your design is translated into a reliable, high-performing reality.

At Sanshun Smart, we combine 10+ years of manufacturing excellence with state-of-the-art SMT lines to provide a seamless transition from design to delivery.

Ready to elevate your manufacturing standards? [Explore our Hardware Capabilities at Sanshun Smart].