The sea is a hostile place, and not just physically. Chemically, the sea is alive and raging, and iron, copper, and other reactive elements don’t stand a chance with respect to any extended stay in the vicinity of marine conditions.

Not to wax poetic, but rust and corrosion are something with which you’ll need to get very familiar if you spend any appreciable amount of time by saltwater.

This brings up the question of boats and electronics - how do you protect them?

Here are 4 big suggestions that will go a long way.

Use Marine Battery Cable in the First Place

What’s that expression? An ounce of prevention is worth a pound of cure? It goes something like that.

In this case, it means this: don’t do your wiring on board boats with anything but approved and appropriate marine battery cable.

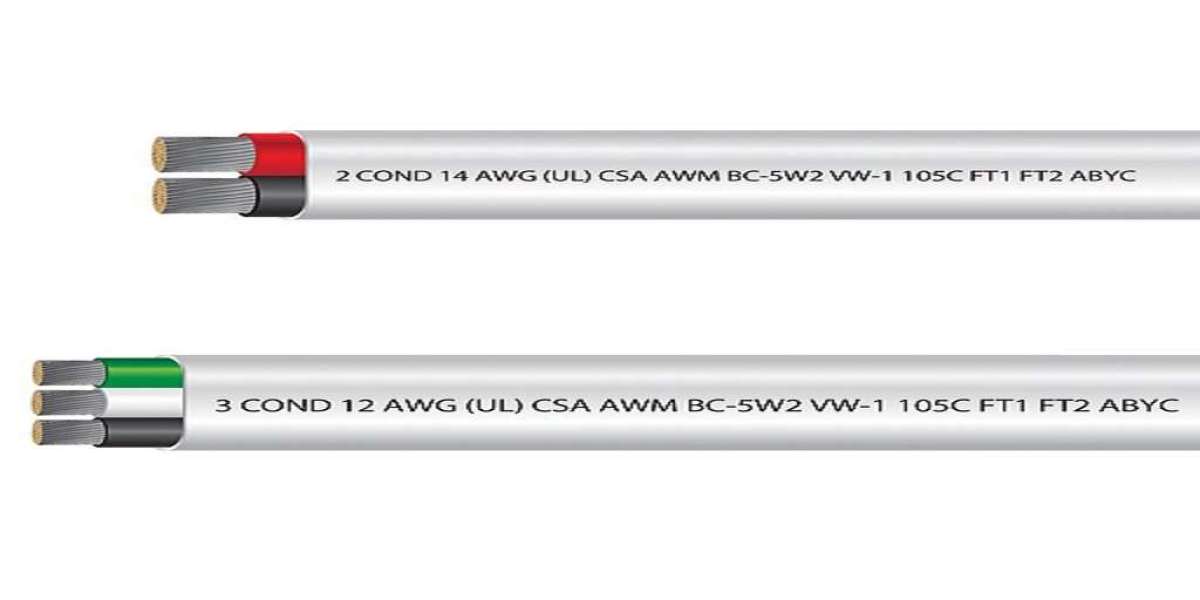

Marine battery cable is like regular battery cable in that it is highly flexible to ensure strong connections, but there’s another layer of protection.

All of the conductors are individually tinned so as to resist corrosion; even if the jacket is compromised and the wire exposed, the tinning helps prevent corrosion from traveling up the wire, underneath the jacket.

It doesn’t eliminate the risk, but let’s put it this way: marine grade battery wire will last much longer in saltwater installations than standard, exposed-copper battery wire.

Use Approved Shrink Tubing

Wherever you must strip your marine battery cable to establish connections, there you should also use approved shrink tubing, where possible, to insulate it.

Once you strip both wires, before you make the connection, slide a piece of shrink tubing over one of the wires that’s approximately twice the diameter of the wire, if not a little more snug.

Make your connection, slide the tubing over the area where naked wire is exposed, and use a lighter, torch or heater to force the tubing to shrink down on the wire.

Don’t Just Trust the Shrink Connection

Where possible, you should not trust passive connections (like shrink tubing alone) to secure your electrical infrastructure. Wherever possible, use a mechanical connector, like an electrical nut, to create a stronger, surer connection.

This will help prevent weak connections that can cause blackouts, arcing, and worse. Doing so is not just a matter of preserving the functionality of your electrical circuits, but of safety at sea.

Apply Dielectric Grease to Exposed Connections

Lastly, if there are any areas where you have some wire exposed, but there’s no other way to insulate it reasonably (which is a condition that you will find happens) one thing you can do to provide a higher level of protection is to apply dielectric grease.

Dielectric grease is a silicone-based insulant that can be applied to exposed wire to help prevent corrosion. There’s just one caveat. Do not allow any of the grease to interrupt the connection.

It is an insulator, so if the grease gets between the two wires, or between the wire or the terminal, it will short out the circuit. Establish your connections, tighten them down, and only then apply dielectric grease if there’s any exposed wire showing.

Here for High-Quality Marine Battery Wire?

If you landed here looking for high-quality marine battery cable to use on vessels or in other marine installations, look no further than EWCS Wire.

EWCS Wire carries a wide range of specialty electrical wire and cable, along with accessories, and carries marine-grade wire, welding cable, aluminum wire, bare copper wire, pump cable, building wire, alarm and instrumentation cable, and much more. Visit their website for more information.

For more information about Aluminum Wire and Fire Alarm Cables Please visit: Electrical Wire & Cable Specialists.