In the hyper-competitive hardware market, your success isn't just about a great design; it’s about supply chain efficiency and manufacturing precision. A disorganized production line leads to wasted components and costly rework. However, by fine-tuning your SMT PCBA manufacturing strategy, you can significantly reduce overhead and boost your product’s reliability.

Here is how industry leaders optimize their process to ensure high yield and lower costs:

1. Precision Solder Paste Deposition

The foundation of a high-yield board starts with the stencil. By utilizing 3D Solder Paste Inspection (SPI), manufacturers can catch volume inconsistencies before components are even placed. This prevents "tombstoning" and bridge defects that haunt cheaper production runs.

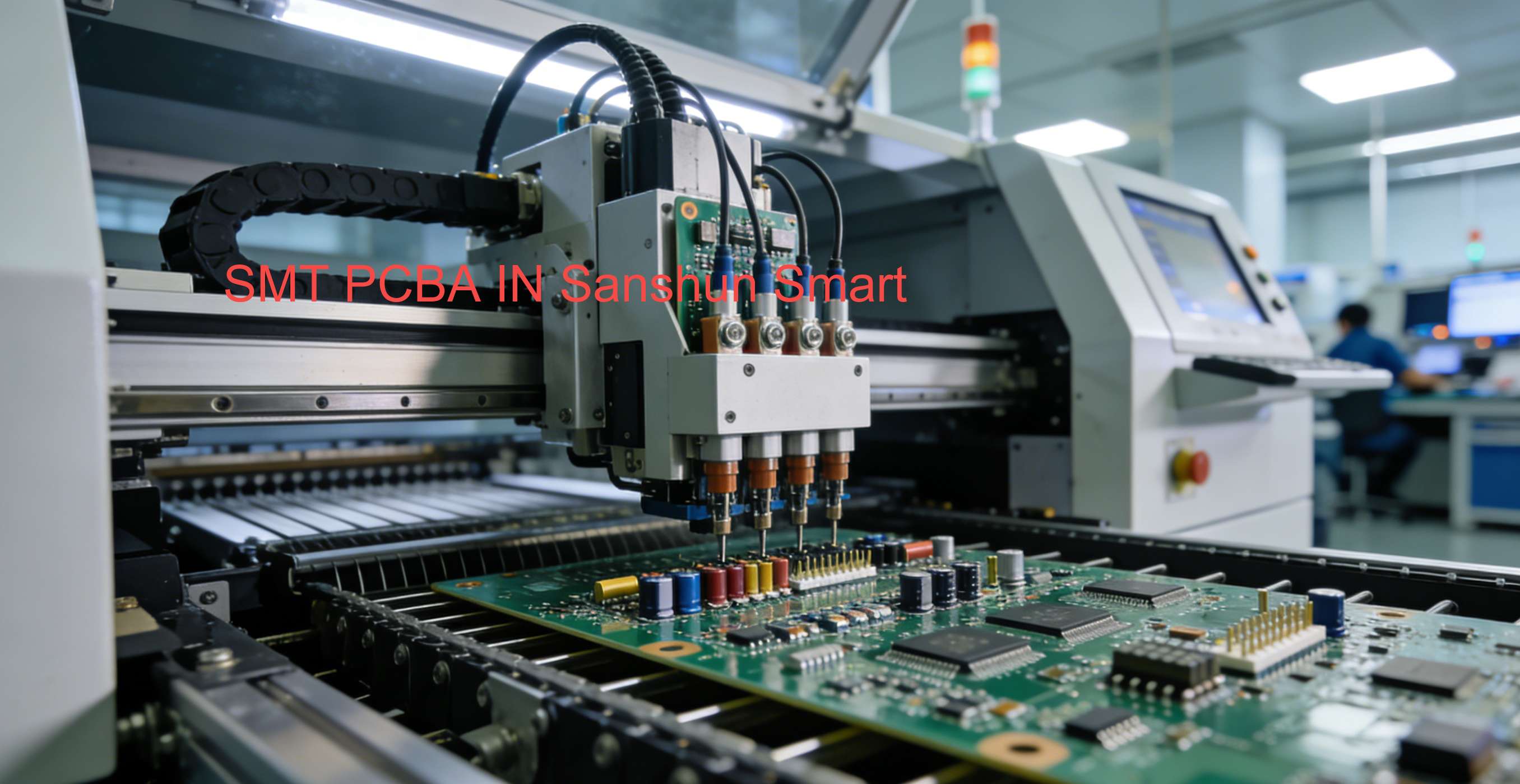

2. Streamlined Pick-and-Place Accuracy

High-speed automated mounting is the heart of the SMT line. Integrating smart feeders and vision-alignment systems ensures that even 0201 or ultra-fine-pitch BGA components are seated with micron-level precision. This eliminates manual corrections and speeds up the "Time to Market."

3. Reflow Profile Optimization

Thermal management during soldering is a science. A professional partner will calibrate the reflow oven’s multi-zone temperature curve to match the specific thermal mass of your PCB. This prevents component stress and ensures long-term joint integrity.

4. Continuous AOI and X-Ray Integration

Quality shouldn't be checked only at the end. By embedding Automated Optical Inspection (AOI) at multiple gates, defects are identified in real-time. For complex multi-layer boards, X-ray inspection is used to verify hidden solder joints, ensuring 100% functional reliability.

5. Partnering with a Technical Expert

Hardware startups often fail because they treat manufacturing as a simple transaction. To truly scale, you need a partner that offers DFM (Design for Manufacturing) feedback to simplify the assembly process. Sanshun Smart has established itself as a leader in this space, providing the specialized equipment and engineering expertise required to navigate complex SMT PCBA manufacturing challenges.

Bottom Line

Optimizing your SMT process isn't just about cutting corners—it's about removing the friction that leads to failure. Choosing a manufacturer that prioritizes precision over-speed alone will save you thousands in the long run.

Ready to elevate your production standards? Explore the advanced equipment and full-turnkey solutions offered by Sanshun Smart to see how they can streamline your next hardware launch.