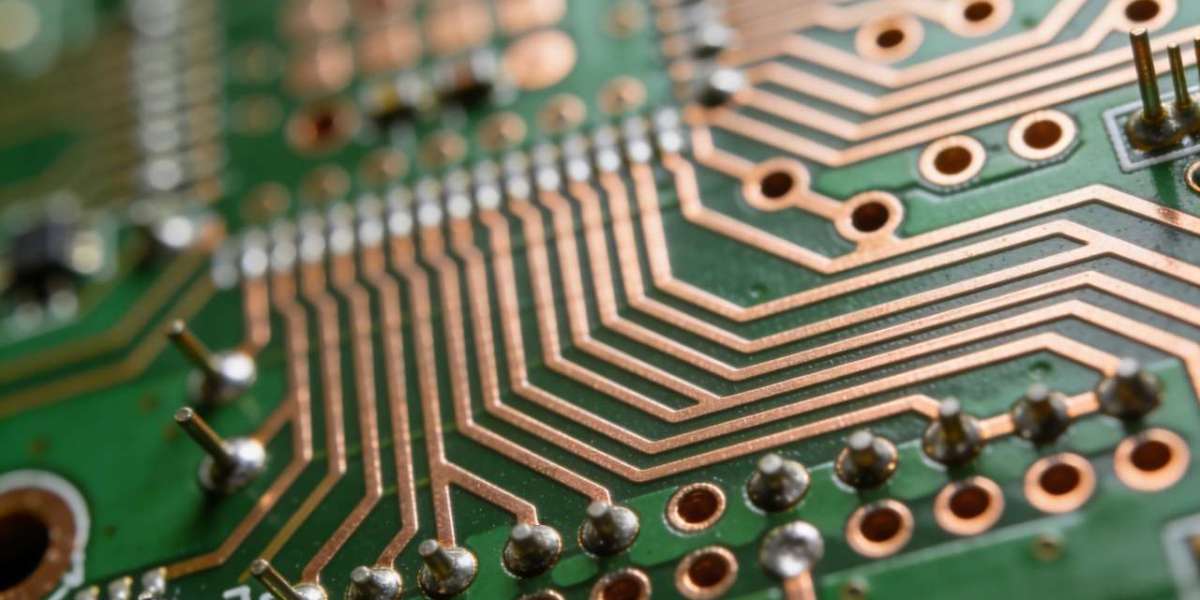

In today’s electronics-driven world, product performance and reliability are no longer defined only by innovative design or advanced software. At the core of every electronic device lies PCBA electronics, which plays a decisive role in determining whether a product performs consistently throughout its lifecycle or fails prematurely in real-world use.

From industrial automation systems to consumer smart devices, the quality of PCBA electronics directly influences electrical stability, signal integrity, and long-term operational safety. Understanding how PCBA electronics work—and what defines high-quality manufacturing—is essential for businesses developing electronic products for global markets.

What Is PCBA Electronics?

PCBA electronics refers to the complete assembly process where electronic components are mounted and soldered onto a printed circuit board (PCB). While a bare PCB provides the physical foundation and circuit pathways, it is the PCBA stage that transforms the board into a functional electronic module.

This process typically includes:

Surface Mount Technology (SMT) assembly

Through-Hole Technology (THT) when required

Precision soldering and reflow processes

Functional and electrical testing

High-quality PCBA electronics ensure that components are accurately placed, securely soldered, and electrically reliable under varying operating conditions.

Key Factors That Define High-Quality PCBA Electronics

Not all PCBA electronics are created equal. The reliability of an assembled board depends on multiple manufacturing factors that go beyond basic assembly capability.

Component Sourcing and Traceability

Using authentic, well-documented electronic components is essential. Traceability helps reduce risks related to counterfeit parts, inconsistent electrical behavior, and unexpected failures in long-term operation.

SMT Accuracy and Soldering Quality

Modern electronics demand fine-pitch components and high-density layouts. Precise SMT placement and controlled soldering profiles are critical to avoiding defects such as cold joints, tombstoning, or solder bridging.

Inspection and Testing Processes

Quality-focused PCBA electronics manufacturing integrates inspection methods such as AOI (Automated Optical Inspection) and functional testing to detect assembly issues early. These steps significantly reduce field failure rates and improve product stability.

Process Consistency for Scale Production

For businesses moving from prototype to mass production, process consistency becomes vital. Stable production workflows ensure that every batch of PCBA electronics meets the same performance and reliability standards.

PCBA Electronics in Real-World Applications

The importance of PCBA electronics becomes even more apparent when viewed through practical application scenarios.

Industrial Control Systems: Require stable electrical performance under vibration, temperature fluctuations, and continuous operation.

Smart Devices and IoT Products: Depend on compact layouts and reliable soldering to maintain signal accuracy and power efficiency.

Automotive Electronics: Demand high-reliability PCBA electronics capable of operating in harsh environments.

Communication Equipment: Requires consistent signal transmission and low electrical noise for dependable connectivity.

Across these industries, PCBA electronics quality directly impacts product lifespan, safety compliance, and end-user trust.

Choosing the Right PCBA Electronics Manufacturing Partner

As electronic products become more complex, selecting an experienced PCBA electronics manufacturing partner is no longer optional—it is a strategic decision. Businesses must look beyond cost considerations and evaluate manufacturing capability, quality control systems, and production scalability.

For companies seeking stable and scalable PCBA electronics manufacturing, working with an experienced partner can significantly reduce production risks. Manufacturers such as Sanshun Smart offer end-to-end PCBA solutions, covering prototype development, mass production, and quality management for a wide range of electronic applications.

By collaborating with a reliable PCBA electronics manufacturer, businesses can focus on product innovation while ensuring consistent manufacturing quality.

Final Thoughts

PCBA electronics is the foundation upon which modern electronic products are built. From component selection to final testing, every step of the assembly process contributes to overall product performance and reliability.

For businesses developing electronics in competitive markets, understanding PCBA electronics—and choosing the right manufacturing partner—can make the difference between a product that succeeds in the field and one that struggles with quality issues. Prioritizing manufacturing expertise, process control, and application experience is the most effective way to ensure long-term success.