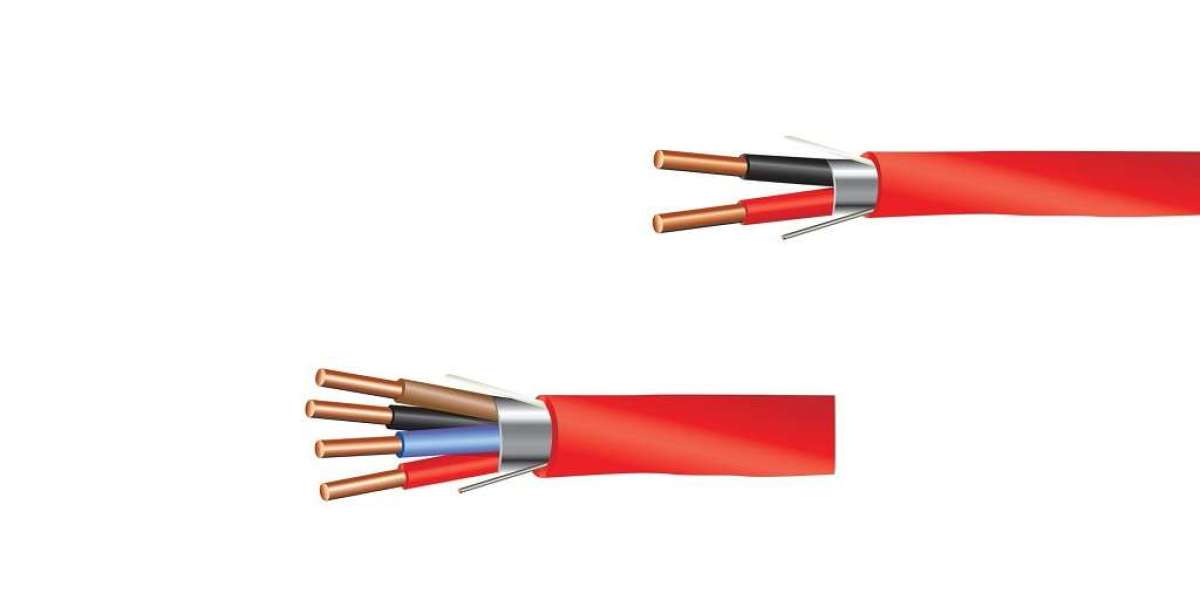

Signal accuracy in fire detection systems isn’t just about the control panel or sensors—it starts with the quality and behavior of the wiring. In large commercial or mixed-use buildings, the performance of fire alarm cables directly determines how quickly and accurately alarms respond during an emergency. Yet, few installation guides or product brochures explore the intricate science behind cable runs, material tolerance, and signal integrity.

The Challenge of Long Runs and Multi-Zone Layouts

As buildings grow more complex, so do their alarm systems. Multi-zone configurations require cables that can carry low-voltage signals over long distances without degradation. Every foot of wire adds electrical resistance, and with it, a slight voltage drop. While this drop may seem negligible on a single floor, it compounds quickly across multi-level networks—especially when hundreds of devices are connected to the same loop.

A signal delayed by even a fraction of a second can alter how panels interpret data, sometimes creating false alarms or missed triggers. To avoid this, integrators need to calculate resistance per length before installation. A common oversight is assuming any 18 AWG conductor will perform equally across 1,000 feet of wiring. In reality, variations in copper purity, strand density, and insulation thickness can cause measurable shifts in resistance and capacitance that affect detection timing.

Understanding Capacitance and Resistance Tolerance

Every cable behaves like a miniature capacitor. It stores and releases small amounts of electrical charge, influencing how a signal propagates. In fire alarm applications, excessive capacitance can round off square wave signals, distorting the data transmitted from detectors to the panel. Materials like tinned copper offer slightly better stability than bare copper in humid or high-oxidation environments because the tin coating minimizes resistance drift over time.

Dielectric materials also play a key role. Polyethylene and polypropylene, for example, have lower dielectric constants than PVC, helping preserve signal sharpness across longer runs. Engineers who specify cabling for high-rise systems often choose low-capacitance designs to maintain consistent signal velocity between zones. Even when codes allow broader tolerances, tighter control over capacitance ensures that the entire loop behaves predictably under load.

Shielding Against Interference

External noise is another hidden factor affecting alarm reliability. In mixed-use structures where alarm wiring often runs beside power cables, HVAC systems, or elevator drives, electromagnetic interference (EMI) can create unwanted pulses on the line. These disturbances can mimic alarm conditions or suppress legitimate signals.

Drain wires, another small but critical feature, provide a continuous path to ground, dispersing collected interference rather than letting it accumulate. Without proper grounding, shielding loses much of its effectiveness, turning a well-designed system into one vulnerable to erratic performance.

The Role of Twisted Pair Geometry

Twisting conductor pairs helps balance electromagnetic fields, further reducing noise pickup. This technique is especially important in addressable systems where digital data is transmitted continuously between devices. Even small differences in loop length or twist rate can alter impedance, leading to communication errors.

In practical terms, a uniform twist pattern ensures that both conductors experience equal exposure to external fields, canceling interference naturally. Twisted pairs not only improve noise rejection but also enhance overall impedance matching—keeping the signal reflections minimal and maintaining integrity throughout the circuit.

Choosing Wisely in Complex Projects

For large-scale or retrofit projects, engineers should evaluate more than just UL listings or voltage ratings. It’s worth reviewing manufacturer data sheets for parameters like nominal capacitance (in pF/ft), conductor resistance (in ohms/1000 ft), and shield coverage (in percentage). Comparing these numbers reveals how different fire alarm cables will perform under real-world conditions rather than just in controlled testing environments.

Designers who specify higher-grade materials often reduce maintenance costs later. When a building adds new zones, merges panels, or upgrades to addressable systems, cables with consistent electrical characteristics simplify integration and troubleshooting. This proactive approach also improves reliability under temperature swings or humidity changes—conditions common in utility chases and rooftop conduits.

Why It All Matters

Signal integrity isn’t just an engineering concept; it directly affects how fast occupants receive alerts and how accurately control panels distinguish between real threats and electrical noise. A well-chosen cable doesn’t only meet code—it ensures that every device in the network performs at its best.

When the goal is safety and long-term reliability, cable selection deserves the same scrutiny as any other life-safety component. For professionals who need guidance on choosing the most stable and compliant fire alarm cables, Electrical Wire & Cable Specialists offers trusted expertise and quality-tested options designed for today’s high-performance systems.

Visit Electrical Wire & Cable Specialists online to learn more about precision-grade cabling solutions for complex alarm installations.

For more information about Flexible Welding Cable and 8 AWG Marine Battery Cable Please visit: Electrical Wire & Cable Specialists.