Precision casting: Crafting Perfection One Pour at a Time

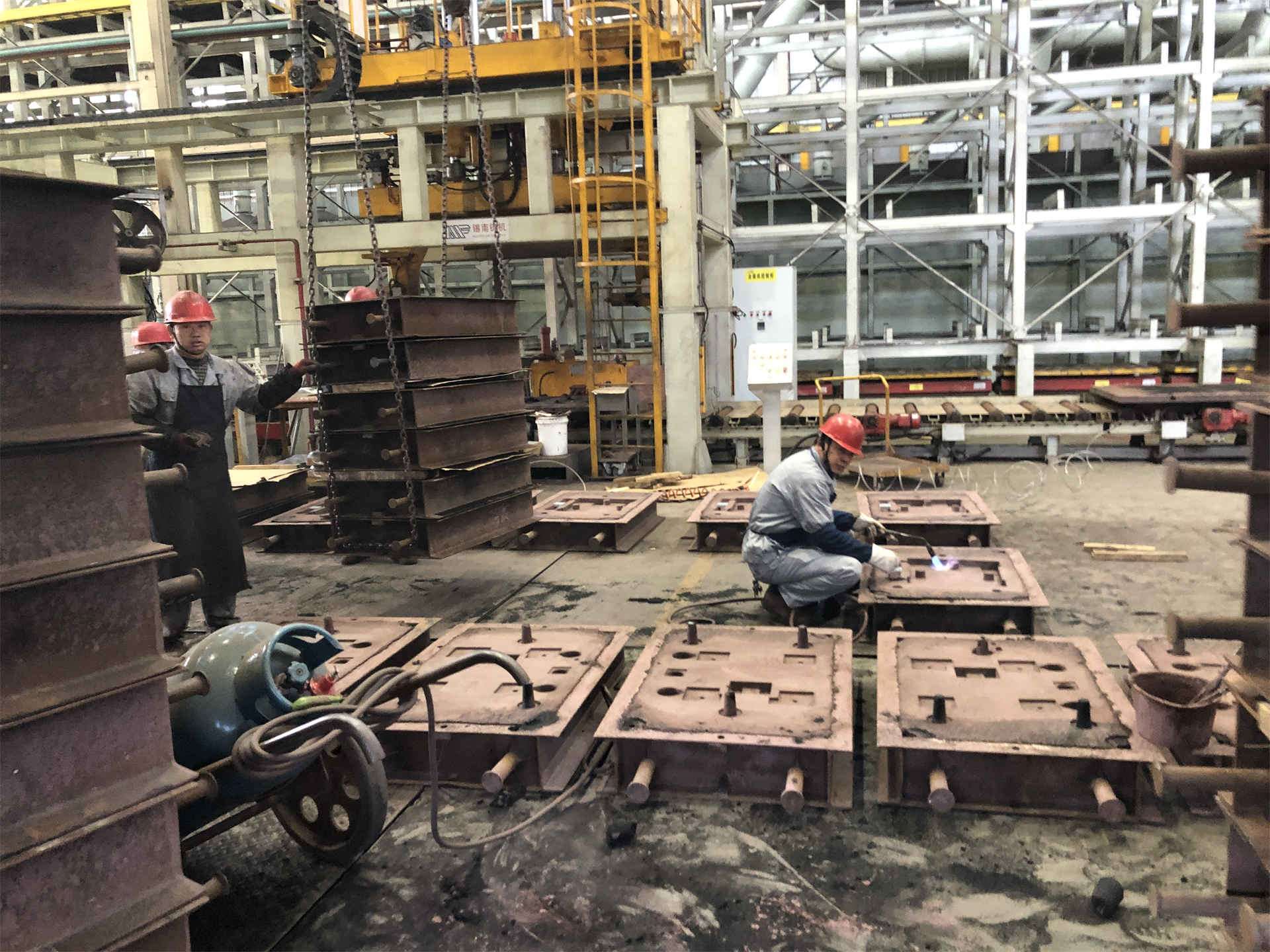

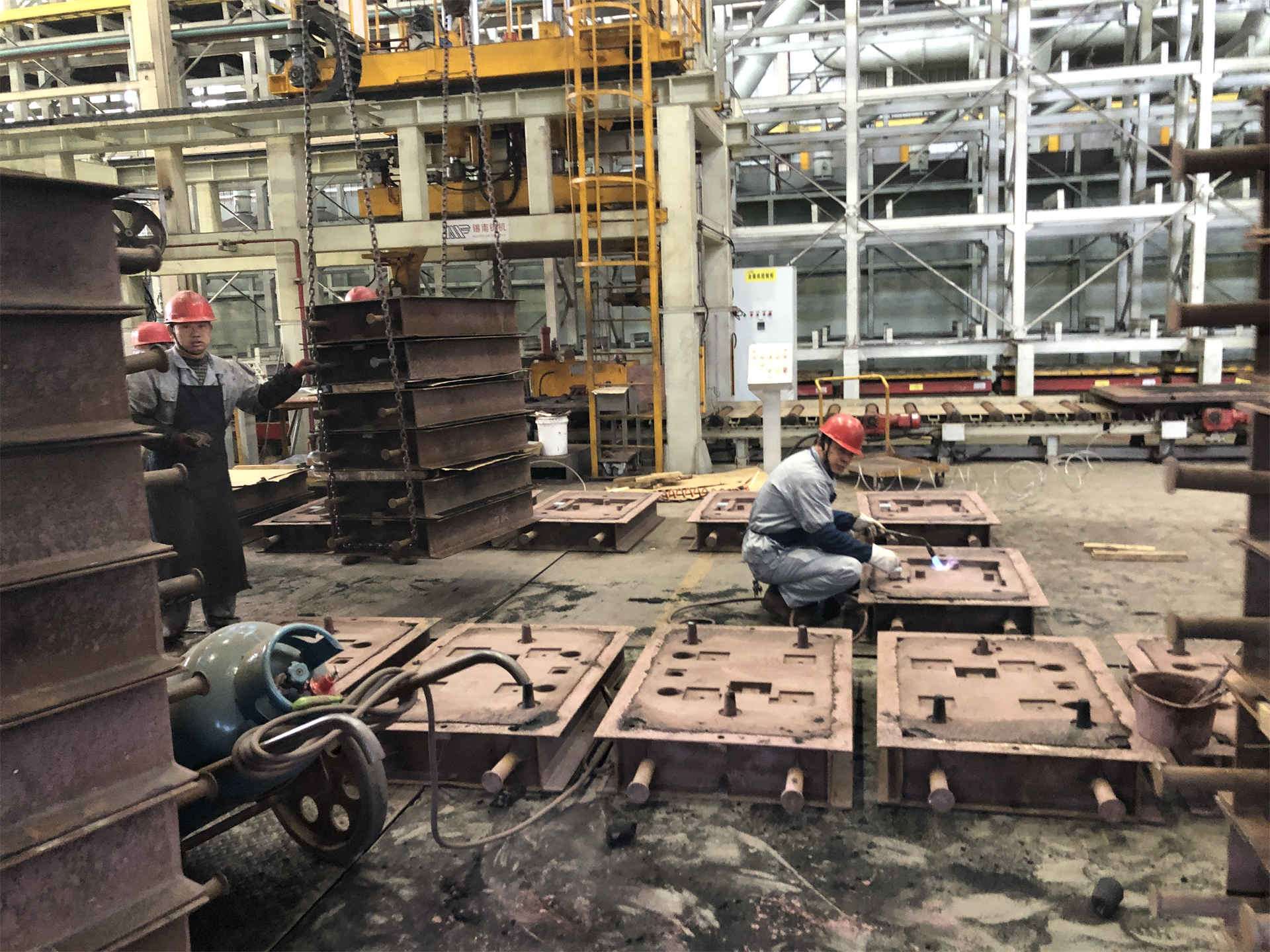

Are you in search of intricate, detailed, and high-quality parts for your next project? Look no further than Precision casting! Precision casting is a manufacturing process that involves pouring molten metal into a mold to create parts with exceptional accuracy and quality. With Precision casting, you can craft perfection one pour at a time and take your projects to the next level.

Precision casting offers a wide range of benefits for your projects. First and foremost, Precision casting allows for the production of parts with complex geometries and tight tolerances. This means that you can get parts that fit perfectly, function flawlessly, and enhance the overall performance of your project.

In addition to precision, Precision casting also offers a high degree of customization. With Precision casting, you can create parts that are tailored to your specific needs, whether it's for functionality, aesthetics, or both. This allows you to stand out from the competition and offer unique and innovative solutions that set your projects apart.

Precision casting is also a cost-effective manufacturing process. By producing parts in large quantities with consistent quality and dimensions, Precision casting reduces waste and labor costs. This allows you to offer high-quality parts at competitive prices, making it an attractive option for both consumers and businesses.

Furthermore, precision casting is versatile. It can be used to create parts for a wide range of industries, including automotive, aerospace, medical, and consumer goods. With precision casting, you can create parts that meet the specific requirements of your project, regardless of the industry or application.

In summary, precision casting is a versatile, precise, and cost-effective manufacturing process that can take your projects to the next level. With precision casting, you can get high-quality parts that enhance the performance and aesthetics of your projects, all while keeping costs low and promoting versatility. Discover the power of precision casting today and craft perfection one pour at a time!