Keşfedin Mesajları

Deepen Your Yoga Journey with 300 Hours Yoga Teacher Training in Rishikesh | ##300hoursyogatraining #yogateachertrainingrishikesh #advancedyogacourse #yogainrishikesh #rishikeshyogaschool #300hourytt #yogacertificationindia #yogaalliancecertified #yogaashramrishikesh #intensiveyogatraining #yogalifestyle #hathayogatraining #ashtangayogarishikesh #meditationandyoga

L'Académie de la Liberté Numérique

Boutique By Eiji Aide les femmes ambitieuses à être libre financièrement. The Digital Wealth Academy 2.0 AOS Academy-Formations trading & DP. Dédiés à ceux qui veulent une carte visa gratuite. Boutique produits beauté pour femmes uniquement. Boutique de produits de beauté en ligne

https://stan.store/Vaihanatamata

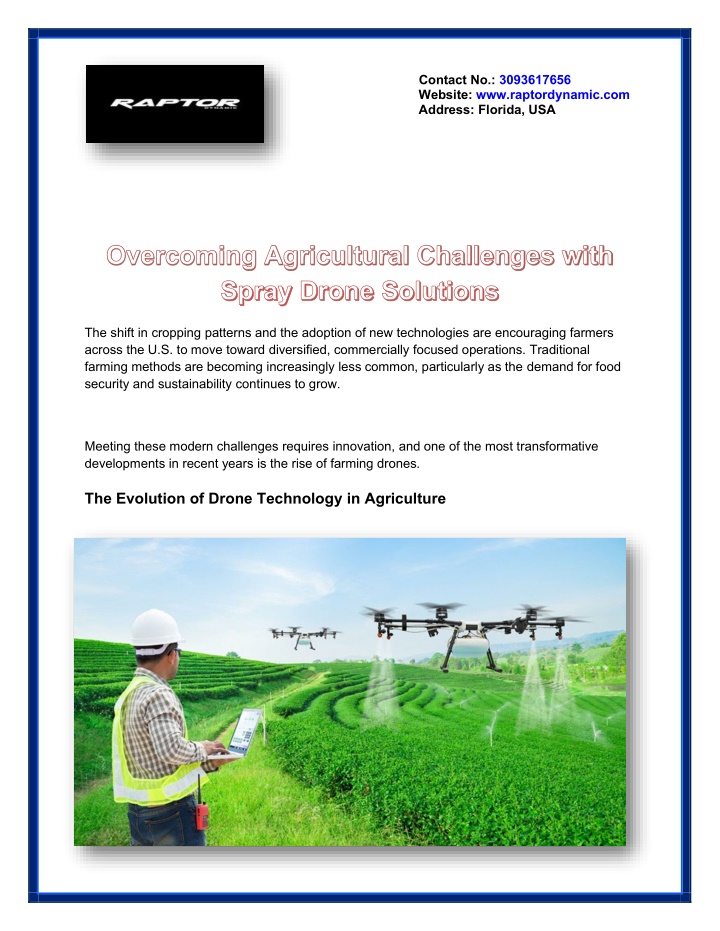

Overcoming Agricultural Challenges with Spray Drone Solutions

Farmers seeking to future-proof their operations can look to solutions like the Vector HD580 for sale and insights from the XAG P150 agricultural drone review to guide their investments. With features like automated delivery systems, terrain-sensitive flight paths, and minimal downtime, today’s spray drones are built for real-world impact.

Read More: https://www.slideserve.com/Rap....tor2/overcoming-agri

#agriculturespraydrone #wetfieldsagriculturedrone #farmdronesprayercost #xagdronedealernearme #heavypayloadagriculturaldrone #xagdronedealernearme

Hire Full Stack Developers to Elevate Your Performance Oriented Web Projects | ##hirefullstackdeveloper ##fullstackdeveloper ##softwaredevelopment

Mọc răng khôn có nên nhổ không? Chuyên gia giải đáp chi tiết | #nhakhoa

The Future of Home Services: 5 Reasons Why Your Business Needs an Uber-Like Handyman App | #handymancloneapp #handymanapplikeuber #handymanapp #ondemandhandymanapp #handymanclonescript #whitelabelhandymanapp #ondemandappdevelopmentcompany #handymanappclonescript

Global Woven Fabric Market Set for Sustainable Growth Amidst Rising Demand Across Industries

https://dataintelo.com/report/....global-woven-fabric-

The global Woven Fabric Market is experiencing strong growth, driven by expanding applications across industries including fashion, automotive, home furnishings, and technical textiles. Woven fabrics—known for their durability, versatility, and performance—are widely used in everything from apparel to industrial gear, making them an essential part of modern manufacturing and consumer goods.

The rise in disposable income, evolving consumer preferences, and increased focus on eco-friendly materials are reshaping demand dynamics. Market players are shifting toward sustainable production methods, including the use of organic and recycled fibers, further boosting the market’s global appeal.