Introduction

India is one of the world’s fastest-growing markets, and as safety and quality regulations become stronger, compliance has become essential. Manufacturers and importers who want to sell regulated products in India must obtain a BIS Certificate under the BIS Certification scheme. Without this certificate, products cannot be legally sold or imported into India.

What is a BIS Certificate?

A BIS Certificate is an official approval issued by the Bureau of Indian Standards (BIS). It confirms that a product meets all Indian safety, quality, and performance standards. Products that fall under mandatory certification must carry the ISI Mark, which shows that the item has passed testing and inspection according to BIS requirements.

A BIS Certificate is mandatory for both Indian manufacturers and foreign manufacturers whose products fall under the Compulsory Certification Scheme (CCS).

Products that often require a BIS Certificate include:

- Electrical appliances

- Steel and metal products

- Cement

- Batteries

- Pressure cookers

- Switches and wiring materials

- Many industrial and consumer goods

If a product is listed under the mandatory category, it cannot be sold in India without a BIS Certificate.

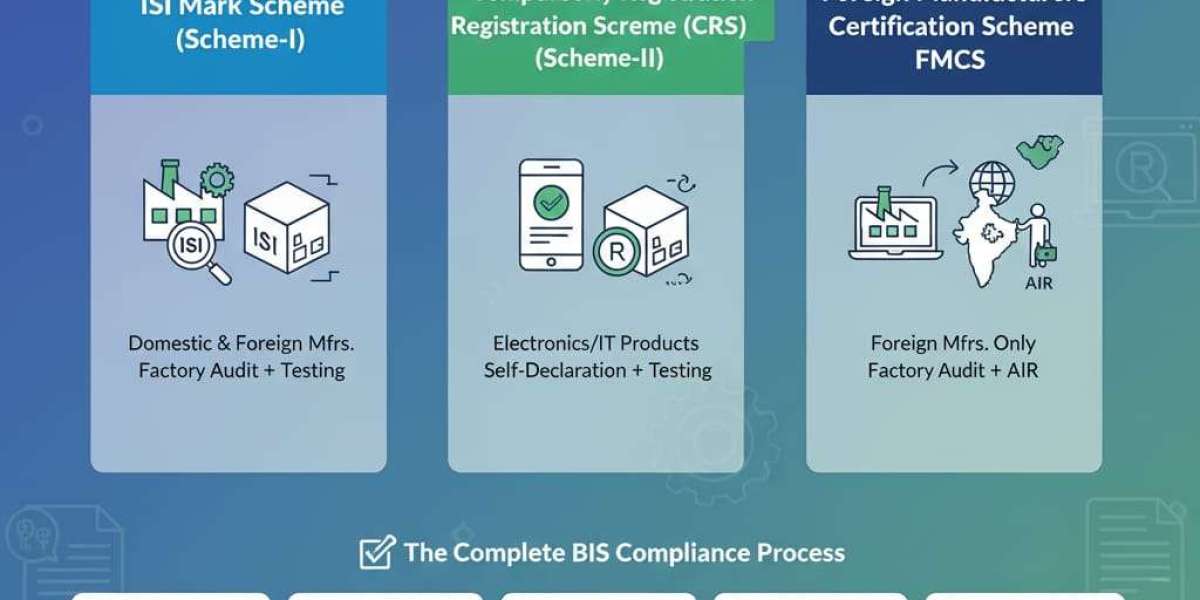

What is BIS Certification?

BIS Certification refers to the complete process through which a manufacturer applies for, tests, and receives the BIS Certificate. The certification ensures that a product undergoes rigorous testing and factory evaluation before being approved for sale.

There are two major certification methods:

1. ISI Mark Certification (Domestic Manufacturers)

For products manufactured inside India.

BIS conducts:

- Factory inspection

- Sample testing

- Quality system verification

After this, BIS issues the ISI Mark license.

2. FMCS Certification (Foreign Manufacturers)

For products manufactured outside India.

Foreign manufacturers must undergo:

- Factory audit by BIS officers

- Qualification testing

- Compliance verification

- Annual surveillance

This is mandatory for exporting regulated goods to India.

BIS Certification is therefore a complete quality assurance mechanism to ensure that products entering the Indian market are safe and reliable.

Why is a BIS Certificate Important?

Obtaining a BIS Certificate offers multiple benefits that can significantly improve a manufacturer’s market presence:

✔ Legal Requirement

Products under mandatory BIS Certification cannot enter the market without the ISI Mark.

✔ Increased Consumer Trust

A BIS Certificate signals high quality, safety, and reliability—key factors influencing customer decisions.

✔ Strong Market Competitiveness

Certified products gain easier access to distributors, retailers, and industrial buyers.

✔ Smooth Customs Clearance

Non-certified goods are stopped at Indian ports. Certified products pass through customs without delays.

✔ Protection from Legal Risks

Non-compliance can lead to penalties, product seizures, and import bans.

Documents Required for BIS Certification

Manufacturers applying for a BIS Certificate must prepare the following documents:

- Business registration documents

- Manufacturing license

- Factory layout plan

- Manufacturing process flowchart

- List of machinery and equipment

- Quality control procedures

- Raw material test reports

- Product specifications and drawings

- Sample test reports from BIS-approved labs

- Authorization letter for BIS inspection

Providing complete and accurate documentation speeds up the approval process.

Step-by-Step BIS Certification Process

The BIS Certification process typically follows these steps:

1. Application Submission

The manufacturer submits the application along with technical documents, product details, and required fees.

2. Document Verification

BIS reviews all submitted documents to ensure they meet certification standards.

3. Factory Audit

A BIS officer conducts an on-site inspection of the manufacturing unit to check:

- Production systems

- Testing facilities

- Machinery and equipment

- Quality management system

4. Product Testing

Samples are collected during the audit and tested in a BIS-recognized laboratory.

5. Evaluation of Results

If the product meets all prescribed Indian Standards, BIS proceeds to the next stage.

6. Issuance of BIS Certificate

Upon successful evaluation, BIS grants the certificate, allowing the manufacturer to use the ISI Mark.

7. Surveillance and Renewal

Periodic audits ensure that the manufacturer continues to maintain quality standards.

Who Needs BIS Certification?

BIS Certification is mandatory for:

- Indian manufacturers

- Foreign manufacturers exporting to India

- Importers of regulated products

- Companies selling electronic and industrial goods in India

If your product falls under any BIS compulsory list, obtaining a BIS Certificate is not optional—it is mandatory.

Conclusion

A sunconsultants.co.in is a critical requirement for manufacturers aiming to enter or expand within the Indian market. The BIS Certification process ensures that products meet India’s strict safety and quality standards, creating trust and credibility among consumers and business partners.