Ever spent weeks perfecting a design, only to watch your mass production hit unexpected delays or lead to costly redesigns? If your prototype PCBA assembly isn’t handled with production-scale foresight, that nightmare becomes reality. In the fast-paced electronic manufacturing services (EMS) industry, hardware teams often prioritize speed over manufacturability during the early stages. However, the way you approach quick-turn prototypes has a massive impact on your final product’s yield, reliability, and total cost of ownership.

Getting it right at the prototyping stage isn't just about getting a working board; it's about validating your Surface Mount Technology (SMT) process for the future. Let’s break down the fundamental differences between prototyping and full-scale manufacturing, and how to bridge the gap without surprises.

1. Is Prototype PCBA Assembly Just "Small Mass Production"?

Actually, no. While mass production focuses on repeatability and unit cost optimization, prototype PCBA assembly is a specialized, low-volume build designed for design validation, debugging, and DFM (Design for Manufacturing) testing.

| Feature | Prototype PCBA Assembly | Mass Production |

| Core Objective | Validation & Debugging | Scalability & Cost Efficiency |

| Typical Volume | 1 - 25 Units | 1,000 - 100k+ Units |

| Setup & Tooling | Minimal NRE Charges | High (Custom Fixtures, Wave Solder Pallets) |

| Lead Time | Quick-turn (3-10 Days) | Standard (4-12 Weeks) |

| Inspection | Manual & Visual / Bench Testing | AOI, X-Ray (AXI), and Automated Functional Testing |

2. Technical Process Differences: Why Context Matters

The jump from a few units to thousands changes how the assembled board is handled. Understanding these shifts helps you avoid "production hell."

DFM and DFT: The Cost-Saving Shield

In the prototype PCBA assembly phase, a thorough DFM and DFT (Design for Test) review can save thousands in redesign fees. At SanshunSmart, we don't just "build to print." We perform BOM scrubbing to identify obsolete components or risky footprints before they reach the assembly line.

Component Sourcing and Lifecycle Risk

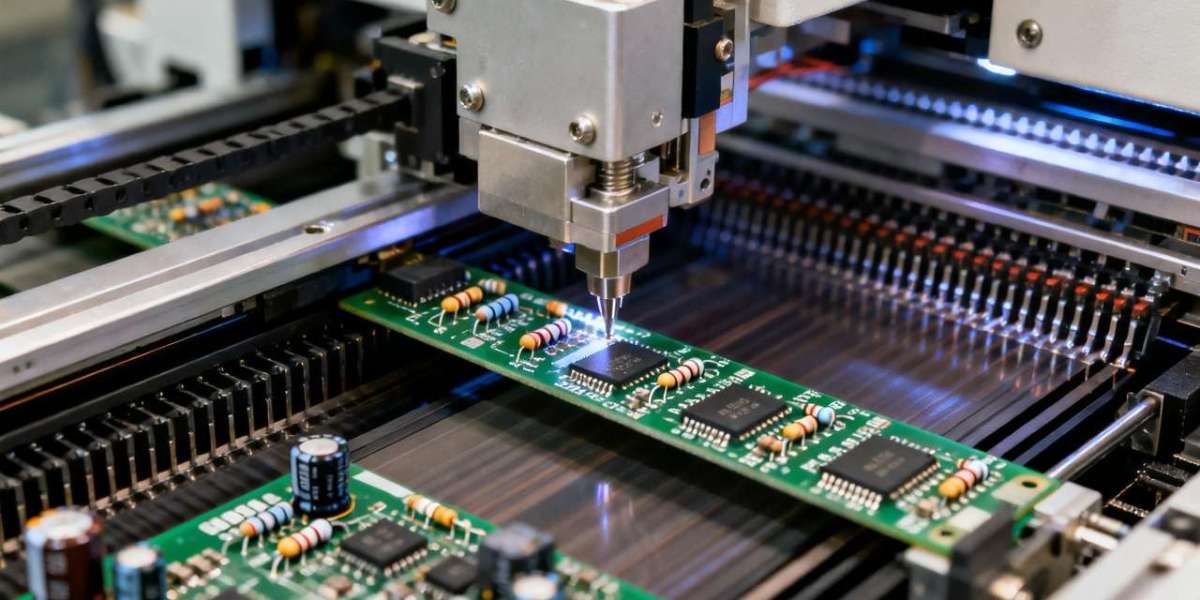

Prototyping allows for some flexibility, like using "cut-tape" or hand-soldering specialized ICs. However, mass production requires components in reels to fit Pick-and-Place machines. Failing to verify the long-term availability of a part during prototyping is a common cause of mass production delays.

3. Why is Prototype PCBA Assembly Priced Differently?

Many teams are surprised by the higher per-unit cost of prototypes. This is driven by Non-Recurring Engineering (NRE) costs, including Stencil fabrication, machine programming time, and manual handling.

Smart hardware teams manage these costs by:

Strategic Planning: Validating critical design points in a single "alpha" run to avoid multiple "beta" revisions.

DFM-First Approach: Running design checks early to ensure the prototype is compatible with high-speed SMT lines.

Transparency: Working with partners like SanshunSmart, who provide clear breakdowns of setup fees vs. component costs.

4. Managing Quality and Latent Risks

The definition of "quality" evolves as you scale:

Prototype Focus: Catching design flaws, polarity errors, or footprint mismatches.

Mass Production Focus: Ensuring First Pass Yield (FPY), process stability, and preventing solder joint fatigue.

Neglecting high-end inspections—like 3D SPI (Solder Paste Inspection)—during the prototype stage can mask underlying issues that only appear as "latent defects" once you hit volume production.

5. Taking Action: Your Pre-Production Checklist

Before transitioning from prototype PCBA assembly to full-scale manufacturing, ensure you have ticked these boxes:

[ ] BOM Verification: Are all components in stock and available for the next 12-18 months?

[ ] Test Coverage: Do you have a scalable testing fixture (ICT or Functional) ready for volume?

[ ] Assembly Feedback: Have you incorporated the "lessons learned" from the assembly technicians during the prototype build?

[ ] Documentation: Is your Pick-and-Place data and Centroid file fully updated and verified?

6. Partnering for the Transition: The SanshunSmart Advantage

Choosing a manufacturer that understands the nuances of both quick-turn builds and large-scale manufacturing is critical. At SanshunSmart, we guide OEMs through the tricky transition from a proof-of-concept to a market-ready product.

By identifying manufacturing risks early and maintaining cost transparency, we help our clients launch reliably without the "hidden costs" of late-stage redesigns.

Ready to bridge the gap? [Contact SanshunSmart today for a DFM-focused quote on your next Prototype PCBA Assembly project.]

FAQ: Prototype vs. Mass Production Insights

Q: Can I use the same manufacturer for both prototypes and mass production?

A: Yes, and it’s often preferred. Using a versatile partner like SanshunSmart ensures that the technical knowledge gained during the prototype build is directly applied to the mass production setup, reducing the "learning curve" errors.

Q: Why do prototypes take 1 week while mass production takes 8 weeks?

A: Prototypes use existing machine capacity and "in-stock" parts. Mass production requires custom material procurement (Lead Times), dedicated line scheduling, and extensive quality documentation.

Q: Does every prototype need a DFM review?

A: If you plan on scaling to more than 100 units, absolutely. A PCBA board that is "hand-soldered" successfully may be impossible for an automated machine to build consistently.