In the realm of chemical manufacturing, understanding production costs is pivotal for both industry players and consumers alike. Among the many compounds synthesized in the chemical world, hexachlorophene stands as a notable subject of scrutiny, particularly in terms of its production expenses. Let's embark on a journey to uncover the intricacies of hexachlorophene production costs, delving into its nuances and conducting a comprehensive cost analysis.

Request Free Sample - https://www.procurementresource.com/production-cost-report-store/hexachlorophene/request-sample

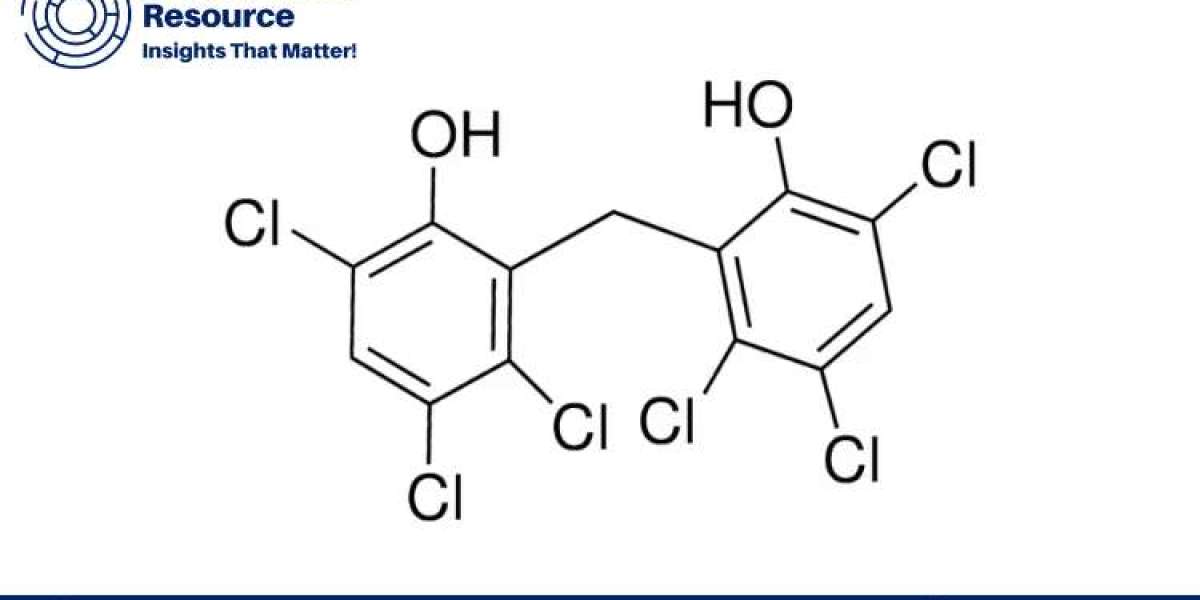

Hexachlorophene: An Overview

Before delving into production costs, it's essential to grasp the significance of hexachlorophene. This chemical compound, often utilized as an antimicrobial agent and a preservative in various products, holds a significant position in both the pharmaceutical and personal care industries. Its applications range from medical formulations to cosmetic products, highlighting its versatility and importance in modern manufacturing.

The Dynamics of Hexachlorophene Production

Hexachlorophene is primarily synthesized through chemical processes involving chlorination of phenols. The production process entails several stages, including raw material procurement, synthesis, purification, and quality control measures. Each step contributes to the overall production cost, thereby warranting a thorough examination to understand cost drivers and potential areas for optimization.

Factors Influencing Production Costs

Raw Material Costs: The cost of phenol, chlorine, and other reagents directly impacts hexachlorophene production expenses. Fluctuations in raw material prices can significantly influence overall production costs.

Energy Consumption: Chemical synthesis processes often require substantial energy inputs, contributing to production expenses. Optimization of energy usage and adoption of energy-efficient technologies can mitigate these costs.

Labor Costs: Skilled labor is indispensable for operating production facilities and ensuring product quality. Labor expenses, including wages, benefits, and training costs, form a significant component of overall production costs.

Regulatory Compliance: Compliance with regulatory standards and environmental regulations necessitates investment in equipment, infrastructure, and compliance-related activities, adding to production costs.

Purification and Quality Control: Rigorous purification processes and quality control measures are essential to ensure product purity and consistency. These measures incur additional costs but are crucial for meeting industry standards and ensuring customer satisfaction.

Production Cost Analysis: Unraveling the Numbers

Conducting a thorough cost analysis is essential for evaluating the economic feasibility of hexachlorophene production. By meticulously scrutinizing each cost component and identifying potential cost-saving opportunities, manufacturers can optimize production processes and enhance profitability.

Conclusion

In conclusion, understanding hexachlorophene production costs is indispensable for stakeholders across industries. By dissecting the intricacies of production expenses and conducting comprehensive cost analyses, manufacturers can make informed decisions, streamline production processes, and ensure cost-effective operations. In a world driven by innovation and efficiency, unlocking the secrets of hexachlorophene production costs is paramount for sustainable growth and success in the chemical manufacturing landscape.